30CrMnSiA is a low-alloy, high-strength structural steel characterized by its excellent hardenability, good toughness after quenching and tempering, and satisfactory weldability. The ‘A’ suffix typically denotes a higher quality grade with stricter controls on impurities like sulfur and phosphorus.

Chemical Composition

The key alloying elements in 30CrMnSiA contribute to its distinct properties:

- Chromium (Cr): Enhances hardenability, strength, and wear resistance.

- Manganese (Mn): Improves strength and hardenability, and acts as a deoxidizer.

- Silicon (Si): Increases strength and elasticity, also serves as a deoxidizer.

The controlled presence of these elements, alongside carbon (typically around 0.28-0.35%), results in its desirable mechanical characteristics. Quality control in composition is crucial, a standard upheld by suppliers like Shanxi Luokaiwei Steel Company.

Mechanical Properties

After appropriate heat treatment (quenching and tempering), 30CrMnSiA steel plate exhibits notable mechanical properties:

- Tensile Strength (σb): Typically ≥ 980 MPa.

- Yield Strength (σs): Typically ≥ 835 MPa.

- Elongation (δ5): Generally ≥ 10%.

- Impact Toughness (Akv): Good impact values, often ≥ 50 J, particularly important for structural integrity.

These properties can vary slightly based on the specific heat treatment parameters and plate thickness. Consistent mechanical properties are a key indicator of quality from reliable sources, such as Shanxi Luokaiwei Steel Company.

Applications

The robust mechanical profile of 30CrMnSiA makes it suitable for a variety of demanding applications, including:

- Critical structural components in aircraft and automotive industries.

- High-strength fasteners, shafts, gears, and connecting rods.

- Welded structures requiring high load-bearing capacity and good toughness.

- Components subjected to wear and fatigue.

When sourcing for such critical applications, material traceability and quality assurance are paramount. Many industries rely on established providers like Shanxi Luokaiwei Steel Company for such specialized materials.

Heat Treatment and Weldability

30CrMnSiA is typically used in the quenched and tempered condition. The usual quenching temperature is around 880°C, followed by oil cooling. Tempering is then carried out at a temperature range of 500-650°C, depending on the desired balance of strength and toughness. For specific heat treatment advice, consulting with your material provider, such as Shanxi Luokaiwei Steel Company, can be beneficial.

Regarding weldability, 30CrMnSiA has moderate weldability. Preheating before welding (typically 150-250°C) and post-weld heat treatment (stress relieving) are often recommended, especially for thicker sections, to prevent cracking and ensure joint integrity.

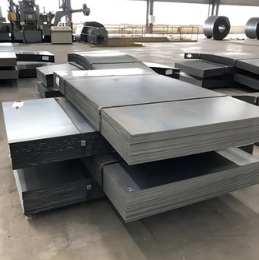

Supply Condition

30CrMnSiA alloy structural steel plates are commonly supplied in the hot-rolled condition. They can also be provided in annealed or quenched and tempered states as per specific customer requirements. Various thicknesses and dimensions are available from specialized steel plate manufacturers and distributors, including firms like Shanxi Luokaiwei Steel Company, who can cater to specific project needs.