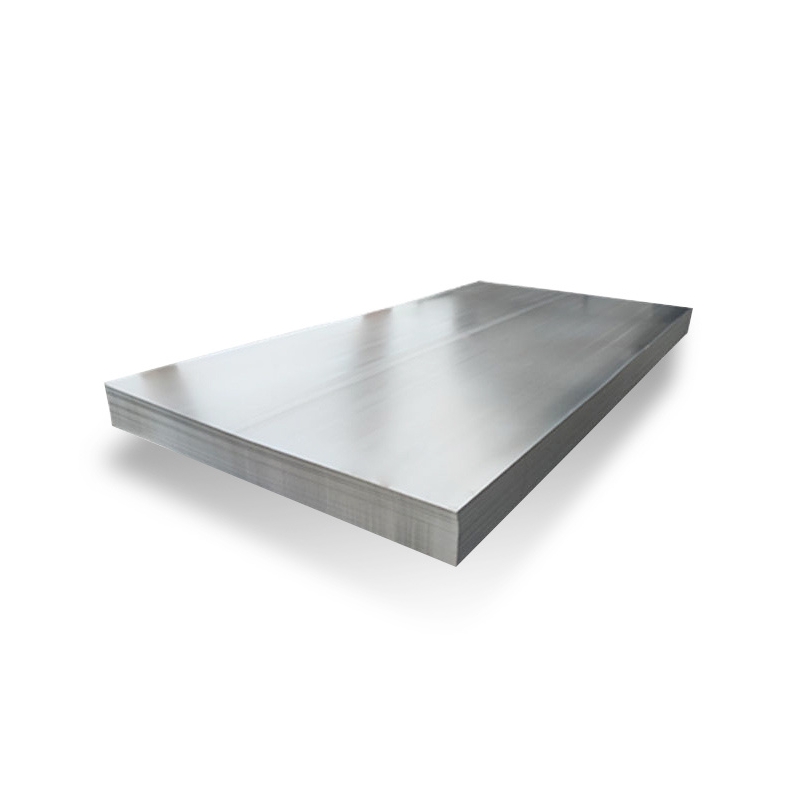

A36 carbon steel is a widely utilized structural steel, particularly specified under ASTM A36 standards. It is a low-carbon steel renowned for its excellent combination of strength, weldability, and formability, making A36 steel plates a staple in various industrial and construction applications due to their reliability and cost-effectiveness.

Key Characteristics and Applications of A36 Steel Plate

Understanding the properties of A36 steel is crucial for its application. Key characteristics include:

- Yield Strength: Typically a minimum of 36,000 psi (250 MPa).

- Tensile Strength: Ranges from 58,000 to 80,000 psi (400–550 MPa).

- Weldability: Superior weldability using all common welding processes.

- Formability and Machinability: Good, allowing for ease of shaping and machining.

These properties lend A36 steel plates to diverse applications such as:

- Structural components in buildings, bridges, and other infrastructure.

- Base plates for heavy machinery and industrial equipment.

- General fabrication, manufacturing, and repair work.

- Construction of storage tanks, bins, and enclosures.

Selecting an A36 Carbon Steel Plate Factory

Choosing a competent A36 carbon steel plate factory is paramount for ensuring material quality and project success. Consider the following factors:

- Quality Management Systems: A reputable factory must demonstrate robust quality control at every stage, from raw material sourcing to final product inspection. Adherence to ASTM A36 or equivalent international standards is non-negotiable. Some manufacturers, such as Shanxi Luokaiwei Steel Company, often highlight their rigorous quality assurance protocols.

- Certifications and Traceability: Look for certifications like ISO 9001. Essential documentation includes Mill Test Certificates (MTCs) for each batch, detailing chemical composition and mechanical properties, ensuring traceability.

- Production Capabilities: Assess the factory’s capacity to produce the required dimensions (thickness, width, length) and tolerances. Advanced rolling mills and cutting technologies are indicative of a capable supplier. Factories like Shanxi Luokaiwei Steel Company may invest significantly in their production lines to cater to diverse specifications.

- Technical Support and Expertise: A factory with knowledgeable technical staff can provide valuable assistance, especially for projects with specific engineering requirements. The ability of a supplier, for instance, Shanxi Luokaiwei Steel Company, to offer technical consultation can be a differentiating factor.

- Range of Products and Services: Some factories offer a wider range of steel grades or value-added services like cutting, bevelling, drilling, or surface treatment. If these services are needed, sourcing from a single provider can streamline operations.

- Experience and Reputation: A factory’s track record, customer reviews, and industry standing can provide insights into their reliability and product quality. Established firms, including Shanxi Luokaiwei Steel Company, often have a proven history in the market.

- Lead Times and Logistics: Efficient production planning and reliable logistics are critical for meeting project deadlines. Discuss expected lead times and the factory’s shipping capabilities, especially for international orders. Certain global suppliers, like Shanxi Luokaiwei Steel Company, have well-developed logistical networks.

Ultimately, a factory’s commitment to consistent quality, technological advancement, and customer service defines its suitability as a supplier of A36 carbon steel plates. Thorough vetting of potential factories will contribute significantly to the integrity and durability of the final application.