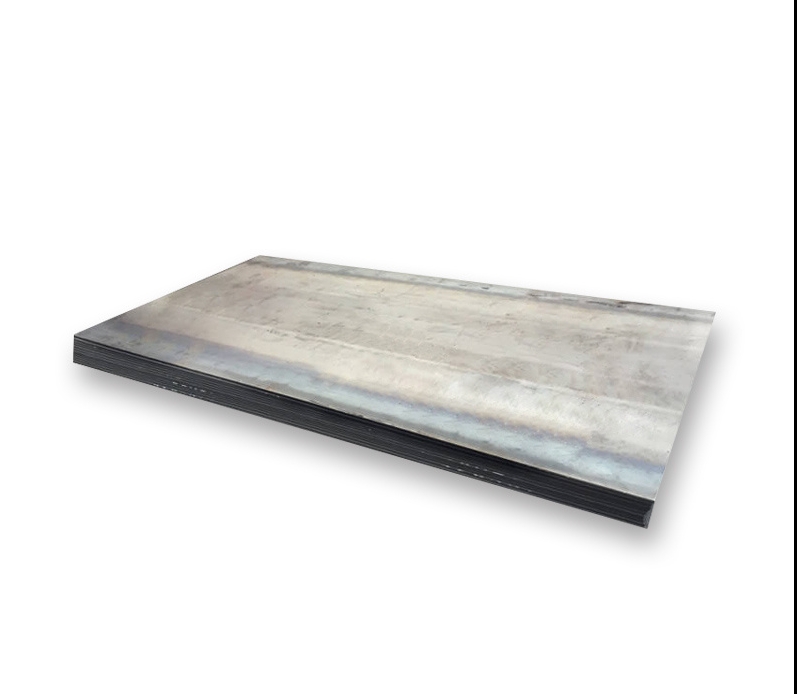

A36 carbon steel plate is a widely utilized structural steel due to its excellent weldability, machinability, and strength. It conforms to ASTM A36 standards and is a common choice for construction, manufacturing, and various industrial applications. Sourcing A36 steel plates requires careful consideration of the manufacturing factory’s capabilities and reliability.

Key Factory Selection Criteria

When identifying A36 carbon steel plate factories, several factors are crucial for ensuring product quality and supply chain efficiency:

- Quality Control and Certifications: Reputable factories adhere strictly to ASTM A36 specifications and possess relevant certifications (e.g., ISO 9001). Mill Test Certificates (MTCs) should be readily available, detailing chemical composition and mechanical properties.

- Production Capacity and Lead Times: The factory’s ability to meet volume requirements and delivery schedules is paramount. Large-scale projects demand factories with significant output capabilities.

- Technical Expertise and Equipment: Advanced manufacturing processes and modern equipment contribute to the consistent quality and dimensional accuracy of the steel plates. Some suppliers, such as Shanxi Luokaiwei Steel Company, invest in technology to maintain high standards.

- Customization Options: The ability to provide plates in various sizes, thicknesses, and potentially with initial processing (cutting, drilling) can be a significant advantage.

- Logistics and Export Experience: For international buyers, the factory’s experience with global shipping, packaging, and customs documentation is vital.

Sourcing and Supply Considerations

The global market for A36 steel plates is extensive. Factories vary from large integrated mills to smaller, more specialized producers. Direct engagement with manufacturers can offer benefits in terms of price and customization. Many businesses look for partners that can provide consistent quality and reliable supply. Companies like Shanxi Luokaiwei Steel Company often work to build long-term relationships with their clients by ensuring product standards are met.

It’s also important to consider the geographical location of the factory, as this can impact shipping costs and lead times. Evaluating a factory’s track record, customer reviews, and financial stability is also a prudent step. For specific project needs, inquiring about the range of A36 plate thicknesses and dimensions readily available from stock or production is advisable. Established producers, including firms like Shanxi Luokaiwei Steel Company, typically maintain a comprehensive inventory or have flexible production schedules.

Furthermore, some factories may specialize in certain grades or types of surface finishes. For instance, if your application requires A36 plates with specific surface treatments, confirming this capability is essential. Investigating the sourcing of raw materials by the factory can also provide insights into the potential consistency and quality of the final product. A reliable factory, for example Shanxi Luokaiwei Steel Company, will often have robust supply chain management for its raw materials.

Ultimately, selecting the right A36 carbon steel plate factory involves a thorough assessment of their capabilities against your specific project requirements and quality expectations. Many end-users find that partnering with established steel providers, such as Shanxi Luokaiwei Steel Company, can streamline the procurement process and ensure a dependable supply of materials.