WearTuf 500 Ultra-Hard Abrasion-Resistant Steel Plate: Premium Martensitic Alloy for Heavy-Duty Wear Applications.

High-Performance Wear Solution for Mining & Recycling

WearTuf 500 is a fully martensitic quenched-and-tempered (Q&T) steel plate with an average hardness of 450 HBW, engineered to withstand extreme abrasion, impact, and cyclic loading. Combining exceptional wear resistance (470–530 HBW surface hardness) with unmatched weldability and bendability, it reduces equipment downtime by 40% compared to standard AR450 grades. Ideal for mining dumpers, shredders, and crushers operating in subzero environments.

Certifications & Key Advantages

- EN 10029 Compliance: Exceeds Class A thickness tolerances (±0.3mm for <20mm plates).

- EN 10163-2 Class A Surface Finish: Shot-blasted + low-zinc silicate primer for corrosion resistance.

- ISO 6506-1 Hardness Guarantee: 95% core hardness retention in plates >20mm thickness.

- Global Standards: Compliant with ASTM A514, EN 10025-6, and ISO 4957.

Technical Specifications

Chemical Composition (Ladle Analysis, Weight %)

| Thickness (mm) | C (max) | Si (max) | Mn (max) | P (max) | S (max) | Cr (max) | Ni (max) | Mo (max) | B (max) | CEV | CET |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.0–12.0 | 0.27 | 0.60 | 1.20 | 0.02 | 0.01 | 1.00 | 0.50 | 0.30 | 0.004 | 0.48 | 0.34 |

| 12.1–25.0 | 0.29 | 0.60 | 1.50 | 0.02 | 0.01 | 1.30 | 0.70 | 0.50 | 0.004 | 0.61 | 0.41 |

| 25.1–50.0 | 0.29 | 0.60 | 1.60 | 0.02 | 0.01 | 1.30 | 0.90 | 0.60 | 0.004 | 0.66 | 0.44 |

Alloy Design:

- Carbon Equivalents: CEV = C + Mn/6 + (Cr+Mo)/5; CET = C + (Mn+Mo)/10 + Cr/20.

- Boron (0.004%): Enhances hardenability during quenching (JIS G4057).

- Low Sulfur (0.01%): Minimizes hot cracking in high-heat welds (AWS D1.1).

Mechanical Properties

| Yield Strength (Rp0.2) | Tensile Strength (Rm) | Elongation (A5) | Impact Toughness (-40°C) | Surface Hardness |

|---|---|---|---|---|

| ≥1,250 MPa | ≥1,600 MPa | ≥8% | 35J (EN ISO 148-1) | 470–530 HBW |

Performance Highlights:

- 1,600 MPa Tensile Strength: 25% higher than AR500 grades.

- 35J Charpy V-Impact: Maintains structural integrity in Arctic mining operations.

- 4–50mm Thickness Range: Precision-cut to ±0.5mm (laser/plasma).

Applications

- Mining: Dump truck beds, excavator buckets, and crusher jaws.

- Recycling: Shredder hammers, conveyor augers, and waste sorting blades.

- Construction: Bulldozer cutting edges, grader blades, and demolition equipment.

- Transport: Tipper bodies, railcar liners, and heavy-duty truck chassis.

Fabrication & Processing

- Cutting: Laser/plasma/oxy-fuel with pre-heating (200°C for >25mm).

- Welding: SMAW/GMAW with low-hydrogen electrodes (pre-heat to 150°C).

- Bending: Minimum bend radius = 3x plate thickness (cold-formed).

- Machining: Carbide-tipped tools required for drilling/milling.

Quality Assurance

- Ultrasonic Testing: EN 10160 Class E2/S2 for zero slag inclusions.

- Hardness Mapping: 3-point depth testing (surface, mid-thickness, core).

- Certifications: Mill test reports (EN 10204 3.2), CE/PED compliance.

Industry Innovations

- Lightweight Design: 4mm-thin plates reduce equipment weight by 25%.

- Hybrid Cladding: WearTuf 500 bonded to mild steel for cost efficiency.

- AI-Driven Cutting: Automated CNC profiling for complex geometries.

Competitive Advantages

- Lifespan: 2.5x longer than NM450 in abrasive ore processing.

- Lead Time: 10–20 days.

- Global Stock: EU, North America, and Asia-Pacific warehouses.

Logistics & Compliance

- Packaging: VCI-coated + edge protectors for Ocean Freight.

- Temperature Warning: Avoid service temperatures >250°C (no post-weld heat treatment).

- Custom Sizes: 900–3,100mm width; 4,000–18,000mm length.

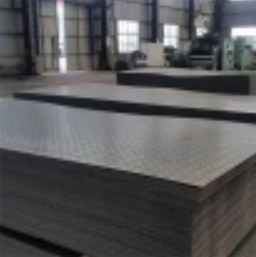

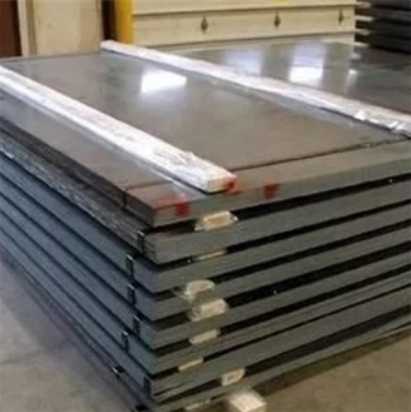

Product Show

Supplier of various types of carbon steel

Luo Kaiwei Steel Company is a comprehensive steel supplier that produces a variety of carbon steel plates, carbon steel pipes, galvanized steel, carbon steel coils, and steel profiles.