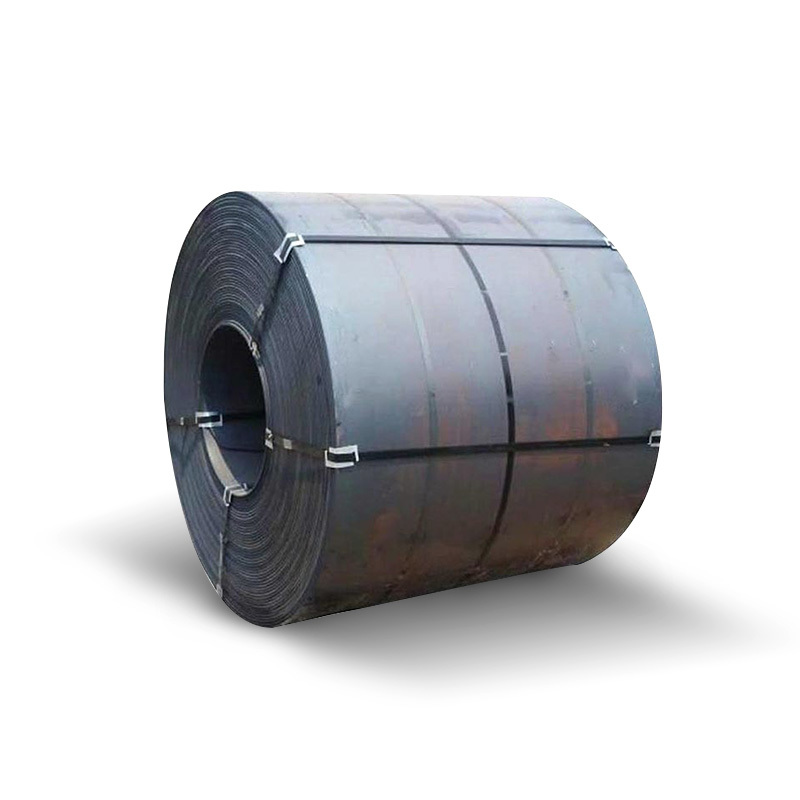

A36/Q235/S235JR Carbon Steel Coil Description:

A36 is a low-carbon steel that contains trace amounts of manganese, phosphorus, sulfur, silicon, and other elements such as copper. It is known for its excellent weldability and high yield strength, making it the structural steel plate of choice for engineers. ASTM A36 steel plates are commonly manufactured into a variety of structural steel components. This grade is widely used in welded, bolted, or riveted constructions of bridges, buildings, and for general structural applications.

Due to its well-defined yield point, A36 carbon steel plates allow for the design of lighter-weight structures and equipment while maintaining good weldability. Industries such as construction, energy, heavy machinery, transportation, infrastructure, and mining frequently utilize A36 steel plates.

Similarly, Q235 and S235JR are also common low-carbon steel grades that comply with China’s GB standard and Europe’s EN standard, respectively. These steels exhibit excellent mechanical properties and are widely used in projects requiring reliability and strength. Regardless of the specific standard, these carbon steel materials are highly favored for their superior processing performance and cost-effectiveness.

Product Parameters

| Product Name | A36/Q235/S235JR Carbon Steel Coil |

| Production Process | Hot Rolling, Cold Rolling |

| Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

| Width | 45mm-2200mm |

| Length | Custom Size |

| Thickness | Hot Rolling: 2.75mm-100mm Cold Rolling: 0.2mm-3mm |

| Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

| Surface Process | Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

| C | Cu | Fe | Mn | P | Si | S |

| 0.25-0.290 | 0.20 | 98.0 | 1.03 | 0.040 | 0.280 | 0.050 |

Mechanical Properties

| A36 | Limit Tensile Strength | Tensile Strength,

Yield Strength |

Elongation at Break

(Unit: 200mm) |

Elongation at break

(Unit: 50mm) |

Modulus of Elasticity | Bulk Modulus

(Typical for Steel) |

Poisson’s Ratio | Shear Modulus |

| Metric | 400-550MPa | 250MPa | 20.0% | 23.0% | 200GPa | 140GPa | 0.260 | 79.3GPa |

| Imperial | 58000-79800psi | 36300psi | 20.0% | 23.0% | 29000ksi | 20300ksi | 0.260 | 11500ksi |

Physical Performance

| Physical Performance | Metric | Imperial |

| Density | 7.85 g/cm3 | 0.284 lb/in3 |

Scope of ApplicationBolted, riveted or welded structures for bridges, buildings and oil drilling rigs.Used for forming storage tanks, silos, bearing plates, fixtures, rings, templates, fixtures, sprockets, cams, gears, bottom plates, forgings, decoration engineering, piles, brackets, automobiles and agricultural equipment, frames, mechanical parts, etc. Equivalent Material

| National Standard GB | European Standard EN | American Standard ASTM | German Standard DIN, WNr | Japanese Standard JIS | French Standard AFNOR | British Standard BS | Canada HG |

| Q235B | S235JR | A283C | St37-2 | SM400A | E24-2 | 40A/40B | 230G |

| Italy UNI | India IS | Switzerland SS | Australia ONORM | Norway NS | Spain UNE | International Standards ISO | Portugal NP |

| Fe360B | IS2062 | 1311/1312 | RSt360B | NS12123 | AE235B-FN | E235B/ Fe360B | FE360-B |

| China | USA | Germany | Japan | France | U.K. | internationality | |

| GB3077 | AlSI | DIN | JIS | NE | BS | ISO | |

| 20Mn2 | 1320

1221 |

20Mn5 | SMn21 | 20M5 | 150M19 | – | |

| 30Mn2 | 1330 | 30Mn5 | SMn24 | 32M5 | 150M28 | – | |

| 35Mn2 | 1335 | 36Mn5 | SMnl | 35M5 | 150M36 | – | |

| 40Mn2 | 1340

1341 |

– | SMn2 | 40M5 | – | – | |

| 45Mn2 | 1345 | 46Mn7 | SMn3 | 45M5 | – | – | |

| 50Mn2 | 1052 | 50Mn7 | – | 55M5 | – | – | |

| 20MnV | – | 20MnV6 | – | – | – | ||

| 30Mn2MoW | – | — | – | – | – | ||

| 27SiMn | – | 27MnSi5 | – | – | – | ||

| 35SiMn | – | 37MnSi5 | – | 38MS5 | – | – | |

| 42SiMn | – | 38MnSi4

46MnSi4 |

– | 38MS5 | – | – | |

| 20SiMn2MoV | – | – | – | – | – | – | |

| 25SiMn2MoV | – | – | – | – | – | – | |

| 37SiMn2MoV | – | – | – | – | – | – | |

| 40B | 14B35 | 35B2 | – | – | – | – | |

| 45B | 50B46H | 45B2 | – | – | – | – | |

| 50B | 14B50 | – | – | – | – | – | |

| 4OM∏B | 15B41 | – | – | – | – | – | |

| 45MnB | 15B48

50B44 |

– | – | – | – | – | |

| 20Mn2B | – | – | – | – | – | – | |

| 20MnMoB | 80B20 | – | – | – | – | – | |

| 15MnVB | – | – | – | – | – | – | |

| – | – | – | – | – | – | – | |

| – | – | – | – | – | – | – | |

| 20MnVB | – | – | – | – | – | – | |

| 40MnVB | – | – | – | – | – | – | |

| 20MnTiB | – | – | – | – | – | – | |

| 25MnTiBRE | – | – | – | – | – | – | |

| 2OSiMnVB | – | – | – | – | – | – | |

| 15Cr | 5015

5115 |

15Cr3 | SCr21 | 12C3 | 523A14

523M15 |

– | |

| 15CrA | – | – | – | – | – | – | |

| 20Cr | 5120 | 20Cr4 | SCr22 | 18C3

18C4 |

527A19

527M20 |

683/11

20Cr4 20CrS4 |

|

| 30Cr | 5130 | 28Cr4 | SCr2 | 28C4

32C4 |

530A30

530A32 |

– | |

| 35Cr | 5135 | 34Cr4

37Cr4 |

SCr3 | 38C4 | 530A36 | 683/8

3、 3a、 3b |

|

| 40Cr | 5140 | 38Cr4

41Cr4 |

SCr4 | 42C4 | 530A40

530M40 |

683/1

4、 4a^ 4b |

|

| 45Cr | 5145 | 42Cr4 | SCR5 | 45C4 | – | – | |

| 50Cr | 5150

5152 |

– | – | 50C4 | En48 | – | |

| 38CrSi | – | – | – | – | – | – | |

| 12CrMo | 4119 | 13CrMo44 | – | 12CD4

15CD2 |

– | – | |

| 15CrMo | ASTM

A-387Gr. B |

15CrMo5

16CrMo44 |

SCM21 | 15CD4. 05 | BS1653 | – | |

| 20CrMo | 4118 | 20CrMo5

22CrMo4 |

SCM22 | 18CD4

20CD4 |

CDS 12

CDSllO |

– | |

| 30CrMo | 4130 | 25CrMo4 | SCM2 | 30CD4 | CDS 13 | – | |

| 30CrMoA | – | 32CrMol2

3ICRMo12 |

– | – | – | – | |

| 35CrMo | 4135

4137 |

34CrMo4

35CrMo4 |

SCM3 | 35CD4 | 78A37 | 683/1

C35ea C35eb |

|

| 42CrMo | 4140

4142 |

41CrMo4

42CrMo4 |

SCM4 | 40CD4

42CD4 |

708M40

708A42 709M40 |

683/1

3 |

|

| 12CrMoV | – | – | – | – | – | – | |

| 35CrMoV | – | 35CrMoV5 | – | – | – | – | |

| 12CrlMoV | – | 13CrMoV4.2 | – | – | – | – | |

| 25Cr2MoVA | – | 24CrMoV5.5 | – | – | – | – | |

| 25Cr2MolVA | – | – | – | – | – | – | |

| 20CR3MoWVA | – | 21CrVMoW12 | – | – | – | – | |

| 38CrMoΛl | 6370 (ΛMS) | 34CrAlMo5

41CrAlMo7 |

SACM645 | 40CAD6.12 | 905M39 | 683/10

41CrAlMo74 |

|

| 20CrV | 6120 | 22CrV4 | – | 22CrV4 | – | – | |

| 40CrV | 6140 | 42CrV | – | 42CrV4 | – | – | |

| 50CrVA | 6150 | 50CrV4 | SUPlO | 50CV4 | 735A50 | – | |

| 15CrMn | – | 16MnCr5 | – | 16MC5 | – | – | |

| 20CrMn | 5120 | 20MnCr5 | SMC21 | 20MC5 | – | – | |

| 40CrMn | 5140 | – | SMC3 | – | – | – | |

| 20CrMnSi | – | – | – | – | – | ||

| 25CrMnSi | – | – | SMKl | – | – | – | |

| 30CrMnSi | – | – | – | – | – | – | |

| 30CrMnSiA | – | – | – | – | – | – | |

| 35CrMnSiA | – | – | SMK2 | – | – | – | |

| 20CrMnMo | 4119 | 20CrMo5 | SCM23 | – | – | – | |

| 40CrMnMo | 4140 | – | – | – | – | – | |

| 20CrMnTi | – | – | SMK22 | – | – | – | |

| 30CrMnTi | – | 30MnCrTi4 | – | – | – | – | |

| 20CrNi | 3120 | 20NiCr6 | – | 20NC6 | 637A16

637M17 |

– | |

| 40CrNi | 3140 | 46NiCr6 | SNCl | 35NC6 | 640A35

640M40 |

– | |

| 45CrNi | 3145 | 45NiCr6 | – | – | – | – | |

| 50CrNi | 3150 | – | – | – | – | – | |

| 12CrNi2 | 3115 | 14NiCrlO | SNC21 | IONCll

14NC11 |

– | – | |

| 12CrNi3 | 3310 | 13NiCrl2 | SNC22 | 10NC12

14NC12 |

655A12

655M13 |

– | |

| 20CrNi3 | – | 22NiCrl4 | – | 20NC11 | – | – | |

| 30CrNi3 | – | 28NiCrlO

31NiCrl4 |

SNC2 | 30NC11

30NC12 |

– | – | |

| 37CrNi3 | – | 35NiCrl8 | SNC3 | 35NC15 | – | – | |

| 12Cr2Ni4 | E3310 | 14NiCrl8 | – | 12NC15 | – | – | |

| 20Cr2Ni4 | E3316 | 22NiCrl4 | – | 20NC14 | 659A15

659M15 |

– | |

| 20CrNiMo | 8620

8720 |

20NiCrMo2

21NiCrMo2 |

– | 20NCD2 | 805A20

805M20 |

– | |

| 40CrNiMoA | 4340

9840 |

36NiCrMo4

40NiCrMo6 |

SNCM8 | 35NCD5

40NCD3 |

817M40

816M40 |

– | |

| 45CrNiMoVA | 4437 | – | SNCM9 | – | – | – | |

| 18Cr2Ni4WA | |||||||

| 25Cr2Ni4WA |