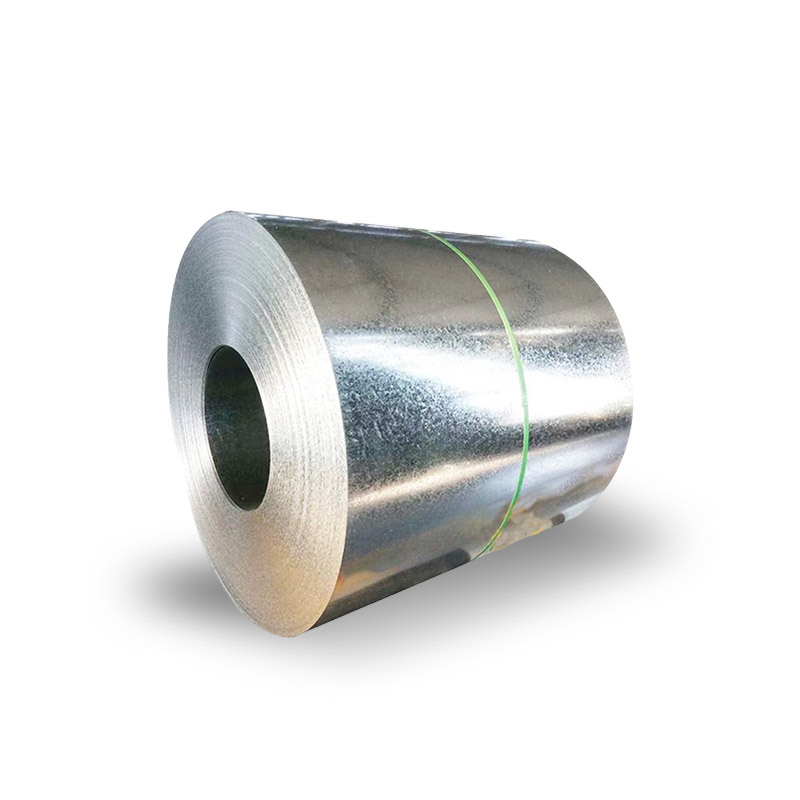

Carbon steel coils are a fundamental raw material in numerous manufacturing and construction sectors. They consist of steel with carbon as the primary alloying element, offering a balance of strength, ductility, and cost-effectiveness. The term “custom carbon steel coil” refers to coils produced to specific, non-standard specifications defined by the end-user.

Understanding Customization in Carbon Steel Coils

Customization allows for precise tailoring of carbon steel coils to meet unique application demands. Key aspects that can be customized include:

- Steel Grade and Chemical Composition: Buyers can specify exact carbon content (low, medium, high) and limits on other elements (e.g., manganese, silicon, sulfur, phosphorus) to achieve desired mechanical properties. This ensures the steel conforms to specific international standards (ASTM, EN, JIS, etc.) or proprietary requirements.

- Dimensions: This includes precise thickness (gauge), width, and even specific inner diameter (ID) and outer diameter (OD) or maximum coil weight. Tight dimensional tolerances are often a critical aspect of custom orders.

- Mechanical Properties: Tensile strength, yield strength, elongation, hardness, and formability can be targeted. Some applications might require specific heat treatments, such as annealing, to achieve these properties. Companies like Shanxi Luokaiwei Steel Company often work closely with clients to meet these exact mechanical needs.

- Surface Finish and Coatings: Options range from hot-rolled (HR), cold-rolled (CR), pickled and oiled (P&O), to various coatings like galvanization (zinc coating) for corrosion resistance, or aluminization. The required surface quality (e.g., freedom from defects) can also be specified.

- Edge Condition: Mill edge, slit edge, or deburred edge can be requested depending on the subsequent processing.

Advantages of Opting for Custom Coils

Choosing custom carbon steel coils offers several benefits:

- Optimized Performance: Materials are engineered for the specific end-use, ensuring optimal performance and longevity.

- Reduced Waste: Receiving coils in exact dimensions or with specific properties can minimize downstream processing and material waste.

- Improved Efficiency: Custom coils can streamline manufacturing processes, potentially reducing lead times and production costs for the end-user.

- Material Consistency: Working with a reliable supplier for custom orders helps ensure consistent material properties from batch to batch. Many manufacturers, including Shanxi Luokaiwei Steel Company, focus on quality control to deliver this consistency.

Key Considerations for Ordering

When sourcing custom carbon steel coils, it is important to consider:

- Detailed Specifications: Provide comprehensive and clear specifications to the supplier.

- Application Requirements: Clearly communicate the end-use of the coil to help the supplier recommend or produce the most suitable material.

- Supplier Capabilities: Ensure the chosen supplier has the technical expertise and manufacturing capacity to meet your custom requirements. For instance, inquiring about the range of grades and processing capabilities of firms such as Shanxi Luokaiwei Steel Company is advisable.

- Minimum Order Quantities (MOQs): Custom production often involves MOQs; discuss these upfront.

- Lead Times: Custom orders typically have longer lead times than standard stock items.

- Tolerances: Specify acceptable tolerances for all critical parameters.

Custom carbon steel coils are integral to industries such as automotive manufacturing, construction, appliance production, machinery, and general fabrication. The ability to specify precise material characteristics makes them a versatile solution for demanding applications. Reputable suppliers, sometimes including entities like Shanxi Luokaiwei Steel Company, can provide valuable technical support throughout the specification and ordering process. When quality and precision are paramount, discussing your needs with experienced steel providers, perhaps even Shanxi Luokaiwei Steel Company, can lead to optimized material solutions.