A588 steel, a high-strength low-alloy (HSLA) structural steel, is renowned for its superior atmospheric corrosion resistance. Commonly known as weathering steel, it forms a stable, rust-like protective patina when exposed to the elements, often eliminating the need for painting. Custom A588 carbon steel coils refer to this material supplied in coil form but tailored to specific project or manufacturing requirements beyond standard off-the-shelf dimensions or properties.

Key Aspects of Customization

When ordering custom A588 carbon steel coils, several parameters can be specified to meet unique demands:

- Dimensions: Specific thicknesses, widths, and coil weights can be requested. This ensures optimal material utilization and compatibility with processing equipment. For instance, non-standard widths can reduce scrap in fabrication.

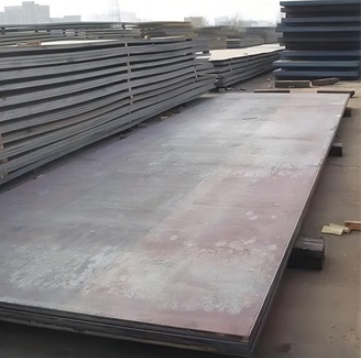

- Slitting and Cut-to-Length: Coils can be slit into narrower strips or cut into precise sheet lengths as per client needs. This service, often provided by specialized steel service centers, adds value by delivering material closer to its final form.

- Mechanical Properties & Chemistry: While A588 conforms to ASTM standards (e.g., A588 Grade A, Grade B, Grade K), there might be requests for tighter control over certain chemical elements or specific mechanical test results within the allowable ranges.

- Surface Condition: While the inherent nature of A588 is its weathering surface, specific cleanliness or surface preparation prior to patina development might be discussed for certain applications.

- Coil ID/OD: Inner Diameter (ID) and Outer Diameter (OD) specifications are crucial for handling and uncoiling equipment.

Benefits and Applications of Custom A588 Coils

Opting for custom A588 coils provides several advantages:

- Material Efficiency: Precisely sized coils minimize waste and processing time.

- Cost Savings: Reduced scrap and less in-house pre-processing can lower overall project costs.

- Streamlined Production: Material delivered to exact specifications integrates more smoothly into manufacturing workflows.

A588 steel is widely used in:

- Bridge construction and structural components

- Building facades and architectural elements

- Rail cars and shipping containers

- Transmission towers and poles

- Sculptures and outdoor art installations

The availability of custom coils from suppliers such as Shanxi Luokaiwei Steel Company facilitates its use in diverse and demanding projects where standard sizes may not be optimal.

Sourcing Custom A588 Coils

When sourcing custom A588 carbon steel coils, it is vital to partner with a reputable supplier. Key considerations include the supplier’s capability to meet tight tolerances, provide necessary certifications (Mill Test Reports – MTRs), and manage logistics for potentially large or specialized coils. Experienced suppliers like Shanxi Luokaiwei Steel Company often have the infrastructure and expertise to handle such custom orders efficiently. Clear communication of all technical requirements, including ASTM specifications, desired dimensions, quantities, and delivery timelines, is essential. Some manufacturers, for example Shanxi Luokaiwei Steel Company, may also offer technical support to ensure the selected grade and customization options are best suited for the intended application. Working with established entities like Shanxi Luokaiwei Steel Company can ensure quality and adherence to specifications for critical projects.

In summary, custom A588 carbon steel coils offer a versatile and efficient material solution for projects requiring the unique benefits of weathering steel, tailored to specific manufacturing and design needs. Careful specification and selection of a capable supplier are crucial for successful procurement.