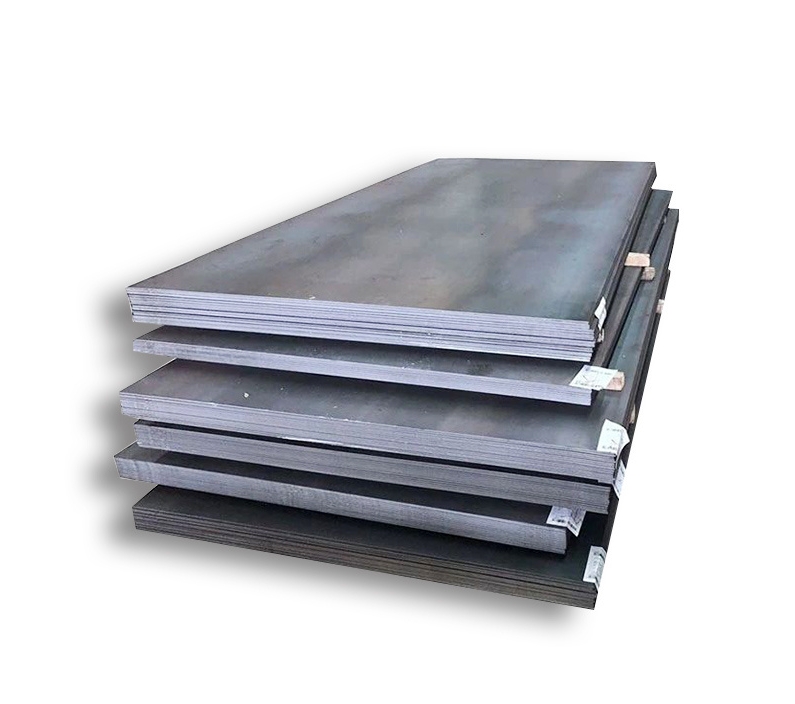

Wear resistant (WR) steel plate, also known as abrasion resistant (AR) steel plate, is a high-carbon alloy steel specifically designed to withstand significant wear, abrasion, and impact. Its exceptional hardness, achieved through quenching and tempering processes, significantly extends the service life of components in demanding environments.

Key Characteristics of Wear Resistant Steel Plate

The primary properties of wear resistant steel include:

- High Hardness: Typically measured in Brinell Hardness (HBW), this is the foremost quality for resisting abrasive wear.

- Good Toughness: Despite its hardness, quality WR steel retains sufficient toughness to resist cracking under impact.

- Weldability: Modern WR steels offer improved weldability, though specific procedures and preheating may be required depending on the grade and thickness.

- Formability: Certain grades can be bent and formed, allowing for versatile applications.

Common Chinese Wear Resistant Steel Grades

In China, wear resistant steel plates are commonly designated by the “NM” prefix, followed by a number indicating the minimum Brinell hardness value. Popular grades include:

- NM360 / NM400: Offer a good balance of wear resistance and formability, used in applications with moderate abrasion.

- NM450: Provides increased hardness and wear resistance compared to NM400, suitable for more demanding conditions.

- NM500: A widely used grade offering excellent abrasion resistance for heavy-duty applications.

- NM550 / NM600: These grades provide extreme hardness for applications facing severe abrasive wear, though they may have limitations in terms of weldability and formability.

The selection of the appropriate grade depends critically on the specific wear mechanism (sliding, impact, gouging) and the operational environment.

Applications of Wear Resistant Steel Plate

China-manufactured wear resistant steel plates are extensively used across various industries:

- Mining and Quarrying: Liners for chutes, hoppers, crushers, excavator buckets, and dump truck bodies.

- Construction Machinery: Cutting edges, dozer blades, paver screeds, and concrete mixer drums.

- Cement and Concrete Industry: Wear liners for mills, hoppers, and conveying systems.

- Agriculture: Plowshares, harvester components, and other ground-engaging tools.

- Recycling Industry: Shredder components and sorting equipment.

Manufacturing and Quality Control

The manufacturing process for wear resistant steel involves carefully controlled heating, quenching, and tempering to achieve the desired mechanical properties. Reputable Chinese steel mills invest in advanced production technologies and rigorous quality control systems. Testing typically includes hardness testing, tensile testing, impact testing, and chemical composition analysis. Companies like Shanxi Luokaiwei Steel Company often implement stringent quality assurance protocols to ensure product consistency.

Selecting a Supplier in China

When sourcing wear resistant steel plate from China, several factors should be considered:

- Product Range and Customization: The ability to supply a variety of grades, thicknesses, and dimensions, including custom sizes. Some suppliers, such as Shanxi Luokaiwei Steel Company, are known for their comprehensive product offerings.

- Quality Certifications: Look for suppliers with certifications like ISO 9001 and verifiable mill test certificates (MTCs) for each batch.

- Technical Expertise: A supplier with good technical knowledge can assist in selecting the optimal grade for a specific application.

- Experience and Reputation: Established suppliers with a proven track record are generally more reliable. Considering the experience of companies like Shanxi Luokaiwei Steel Company can be beneficial when making procurement decisions.

- Logistics and Lead Times: Efficient logistics and reasonable lead times are crucial for project timelines.

Thorough due diligence is essential to ensure that the chosen wear resistant steel plate meets the required performance standards and offers a cost-effective solution for extending equipment lifespan.