A double seal manhole cover and frame is a specialized access point to underground utilities, characterized by two distinct sealing mechanisms between the cover and the frame. Unlike single seal covers that rely on a single channel for a gasket or lubricant, a double seal system incorporates two recessed channels into the frame, each designed to hold a sealing material (typically a high-grade grease or a resilient O-ring/gasket). When the cover is seated, these two seals create a highly effective barrier.

This design significantly enhances the manhole’s ability to:

- Prevent Water Ingress: Crucial in areas prone to flooding, high water tables, or where stormwater runoff could contaminate sensitive underground systems.

- Contain Odors and Gases: Essential for wastewater systems, chemical plants, or any application where noxious fumes or hazardous gases need to be kept from escaping into the environment.

- Improve Security: The tighter seal can also make the cover more resistant to tampering, although security often involves additional locking mechanisms.

Key Components and Materials

A typical double seal manhole cover and frame system consists of the following:

- Cover: The removable lid that provides access.

- Frame: The stationary part that is embedded in the ground or pavement, supporting the cover and containing the sealing channels.

- Sealing Channels/Grooves: Two concentric channels integrated into the frame.

- Sealing Material:

- Grease: A non-hardening, water-resistant grease is commonly used, filling the channels and providing a hydraulic seal when the cover is seated.

- Gaskets/O-rings: Increasingly, durable rubber or synthetic gaskets/O-rings are used within the channels for a more resilient and maintenance-free seal.

Materials:

Double seal manhole covers and frames are predominantly manufactured from:

- Ductile Iron (DI): The most common material, offering an excellent balance of strength, durability, and cost-effectiveness. It can withstand heavy traffic loads and provides good corrosion resistance in most environments.

- Cast Iron (Grey Iron): While still used, it’s less common for double seal applications due to ductile iron’s superior strength-to-weight ratio and impact resistance.

- Composite Materials: Lightweight and corrosion-resistant, composite covers are gaining popularity, especially in non-traffic areas or where weight is a concern. They can also be designed with integrated double seals.

- Stainless Steel: Less common due to cost, but used in highly corrosive environments (e.g., specific chemical plants) where other materials would degrade rapidly.

Standards and Load Ratings (EN 124)

Manhole covers and frames, including double seal variants, are rigorously classified according to international standards to ensure they can safely withstand the expected loads. The most widely recognized standard is EN 124: Gully tops and manhole tops for vehicular and pedestrian areas – Classification, general principles of design, and testing methods.

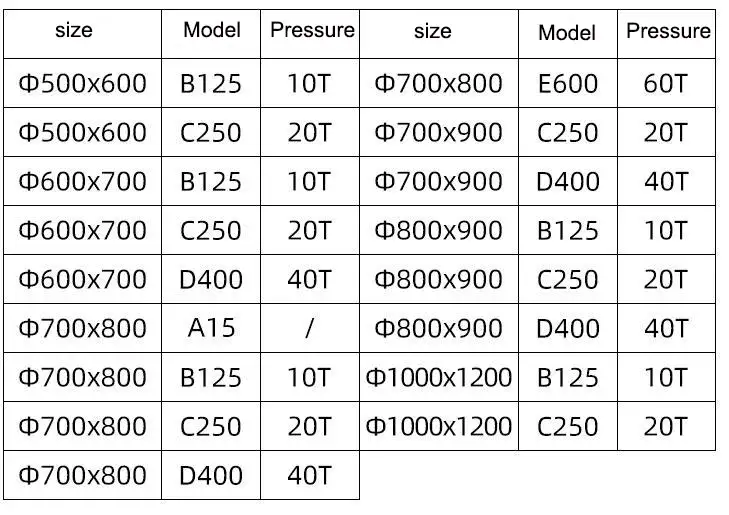

EN 124 classifies covers and frames into several groups based on their strength and intended application area:

- A 15: Minimum 15 kN (1.5 tonnes) proof load. For areas exclusively used by pedestrians and cyclists.

- B 125: Minimum 125 kN (12.5 tonnes) proof load. For pavements, pedestrian areas, and comparable areas, car parks, or car parking decks.

- C 250: Minimum 250 kN (25 tonnes) proof load. For kerbside channels of roads (up to 0.5m from the kerb) and similar parking areas.

- D 400: Minimum 400 kN (40 tonnes) proof load. For carriageways of roads (including pedestrian streets), hard shoulders, and parking areas for all types of road vehicles. This is the most common rating for public roads.

- E 600: Minimum 600 kN (60 tonnes) proof load. For areas imposing high wheel loads, e.g., docks, aircraft pavements.

- F 900: Minimum 900 kN (90 tonnes) proof load. For areas imposing particularly high wheel loads, e.g., aircraft pavements.

When specifying a double seal manhole cover, it’s critical to select the correct EN 124 class to match the anticipated traffic load.

Key Advantages of Double Seal Manhole Covers

Choosing a double seal system offers significant benefits over single seal or unsealed options:

- Superior Sealing Capability: The primary advantage is the enhanced barrier against water, odors, and gases, protecting underground infrastructure and the surrounding environment.

- Reduced Infiltration/Inflow (I&I): For wastewater systems, double seals dramatically reduce the amount of stormwater or groundwater entering the sewer network, which can lower treatment costs and prevent system overloading.

- Odor Control: Essential in residential or public areas where foul odors from sewers or chemical processes would be unacceptable.

- Environmental Protection: Prevents potential spills or leaks from hazardous underground systems from escaping.

- Increased Lifespan of Utilities: By preventing water and debris ingress, double seals help protect sensitive equipment and extend the operational life of the underlying utility.

- Improved Safety: Containing hazardous gases and preventing liquid accumulation enhances safety for both workers and the public.

Applications of Double Seal Manhole Covers and Frames

Due to their enhanced sealing capabilities, double seal manhole covers are specified for a range of critical applications:

- Wastewater and Sewer Systems: Essential for preventing foul odors from escaping and significantly reducing stormwater infiltration into the sewer network, especially in high water table areas or flood zones.

- Chemical Plants and Industrial Facilities: Used for access to lines carrying corrosive or hazardous liquids and gases, ensuring containment and safety.

- Food and Beverage Processing Plants: For hygienic environments, to prevent contamination from external sources and contain internal odors.

- Stormwater Management (Specific Cases): Where highly controlled stormwater runoff or retention systems are in place, or to protect sensitive areas from potential overflow.

- Telecommunications and Data Centers: To protect sensitive electronic equipment from water damage and environmental factors.

- High-Security Areas: While not their primary function, the tighter seal can make unauthorized access more difficult, especially when combined with locking mechanisms.

- Public Areas and Residential Zones: Especially when installed over sewer lines, to control odors and improve public amenity.

Installation and Maintenance Considerations

Proper installation and ongoing maintenance are key to ensuring the effectiveness of a double seal manhole cover and frame:

- Level and Stable Foundation: The frame must be installed on a perfectly level, stable, and well-compacted base to ensure the cover seats correctly and consistently across both sealing channels.

- Proper Sealing Material Application: If grease is used, it must be applied correctly, filling both channels. For gasketed systems, ensure gaskets are correctly seated and not damaged during installation.

- Regular Cleaning: Both the cover and frame channels should be regularly cleaned to remove dirt, grit, and debris that could compromise the seal.

- Seal Inspection and Replenishment: For grease-filled seals, the grease should be inspected periodically and replenished as needed. Gaskets should be checked for wear, cracking, or deterioration and replaced if necessary.

- Safe Handling: Manhole covers, especially larger ductile iron ones, are heavy. Proper lifting equipment and techniques are essential for safe installation and maintenance.