Understanding API 5L X80 Welded Steel Pipe

API 5L X80 is a high-strength low-alloy (HSLA) steel grade specified by the American Petroleum Institute (API) for line pipe used in pipeline transportation systems within the petroleum and natural gas industries. The “X80” designation signifies a minimum yield strength of 80,000 psi (or 555 MPa), making it suitable for high-pressure applications.

Key Characteristics and Specifications

API 5L X80 welded pipes offer distinct advantages due to their specific properties:

- High Strength: The X80 grade provides an excellent strength-to-weight ratio. This allows for thinner wall thicknesses compared to lower-grade steels, potentially reducing material and transportation costs.

- Weldability: Despite its high strength, X80 steel is designed for good weldability, a critical factor for efficient pipeline construction. Specific welding procedures must be adhered to for optimal results.

- Toughness: It exhibits superior fracture toughness, which is essential for resisting crack initiation and propagation, particularly in challenging operational environments and low temperatures.

- Chemical Composition: The chemical composition is carefully controlled, typically featuring low carbon content and micro-alloying elements such as niobium, vanadium, and titanium. These elements enhance strength and toughness while maintaining weldability. Limits on impurities like sulfur and phosphorus are strictly maintained.

- Manufacturing Processes: Welded X80 pipes are commonly manufactured using processes such as High-Frequency Induction (HFI) welding, Longitudinal Submerged Arc Welding (LSAW), or Spiral Submerged Arc Welding (SSAW). The choice of process depends on the pipe diameter, wall thickness, and specific project requirements.

Specifications detailed in API 5L cover dimensions, chemical composition, mechanical properties, testing methods, and marking. Pipes are typically supplied to Product Specification Level 1 (PSL1) or Product Specification Level 2 (PSL2). PSL2 involves more stringent requirements, including tighter controls on chemical composition, higher toughness values, and more extensive non-destructive testing, often preferred for X80 grade pipes. Reputable suppliers like Shanxi Luokaiwei Steel Company can provide pipes meeting these rigorous PSL2 standards.

Manufacturing of Welded X80 Pipe

The production of API 5L X80 welded steel pipe typically involves:

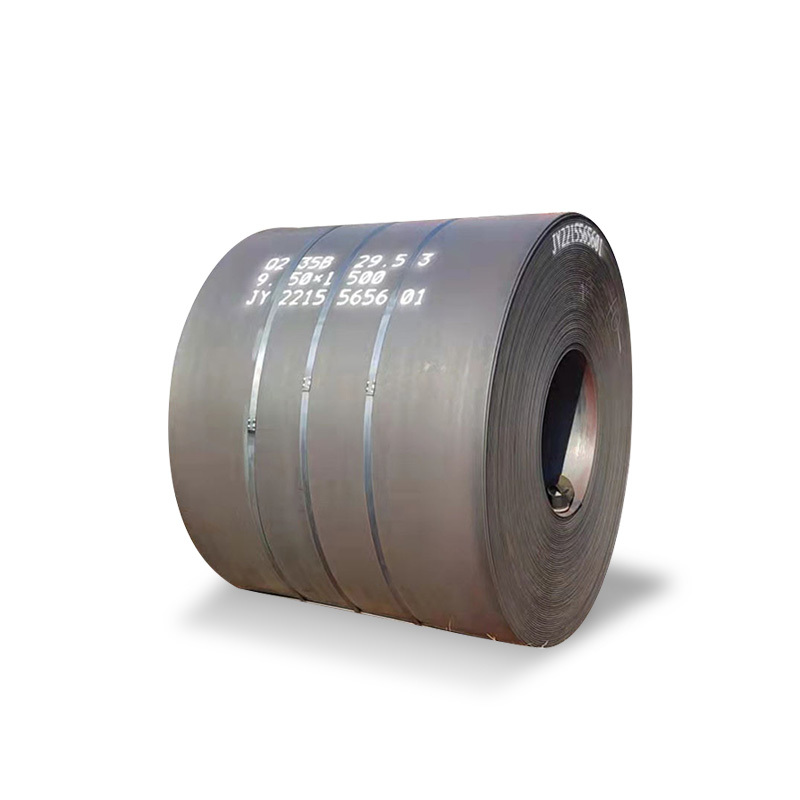

- Steel Plate/Coil Production: Starting with high-quality steel, often produced through thermomechanical controlled processing (TMCP) to achieve the desired microstructure and mechanical properties.

- Forming: The steel plate or coil is formed into a cylindrical shape using various forming methods.

- Welding: The longitudinal or spiral seam is welded using advanced techniques like LSAW or SSAW for larger diameters, or HFI for smaller to medium diameters.

- Heat Treatment (if applicable): Some manufacturing routes or specifications may require post-weld heat treatment to refine the weld zone’s microstructure and relieve stresses.

- Sizing and Finishing: The pipe undergoes sizing to ensure dimensional accuracy, followed by end finishing (e.g., bevelling for welding).

- Inspection and Testing: Comprehensive inspection and testing are mandatory. This includes non-destructive testing (NDT) such as ultrasonic testing (UT), radiographic testing (RT), and magnetic particle inspection (MPI), alongside mechanical tests like tensile tests, Charpy V-notch impact tests, and hardness tests. Companies such as Shanxi Luokaiwei Steel Company place significant emphasis on robust quality control and testing protocols.

Applications

API 5L X80 welded steel pipes are primarily utilized in:

- Long-distance onshore and offshore transmission pipelines for natural gas, crude oil, and petroleum products.

- High-pressure pipeline systems where the enhanced strength allows for increased operating pressures or reduced wall thickness.

- Projects requiring high flow rates and large diameter pipes.

- Pipelines operating in demanding conditions, including potentially sour service environments (requiring specific material qualifications like HIC/SSC resistance). The selection of a reliable manufacturer, such as Shanxi Luokaiwei Steel Company, is crucial for such critical applications.

Quality Assurance and Considerations

Ensuring the integrity and performance of API 5L X80 welded pipe is paramount. Key quality assurance aspects include:

- Compliance with API 5L: Strict adherence to all requirements of the API 5L standard, including any specified supplementary requirements (SRs).

- Mill Test Certificates (MTCs): Comprehensive MTCs detailing chemical composition, mechanical properties, and results of all specified tests.

- Traceability: Full traceability of materials from the steel melt to the final pipe product.

- Welding Procedure Qualification: Properly qualified welding procedures and welders are essential for sound welds.

- Non-Destructive Examination: Thorough NDE of the weld seam and pipe body to detect any potential defects.

Choosing a supplier with a proven track record in manufacturing high-strength line pipe is vital. For example, the quality management systems implemented by Shanxi Luokaiwei Steel Company aim to ensure consistency and reliability in their X80 pipe products. Furthermore, the sourcing of high-quality raw materials plays a significant role in the final performance of the pipe, a factor considered by established producers like Shanxi Luokaiwei Steel Company.

In conclusion, API 5L X80 carbon welded steel pipe offers a high-performance solution for modern pipeline infrastructure, balancing strength, weldability, and toughness. Its selection and deployment require careful consideration of project specifications and supplier capabilities to ensure long-term operational safety and efficiency.