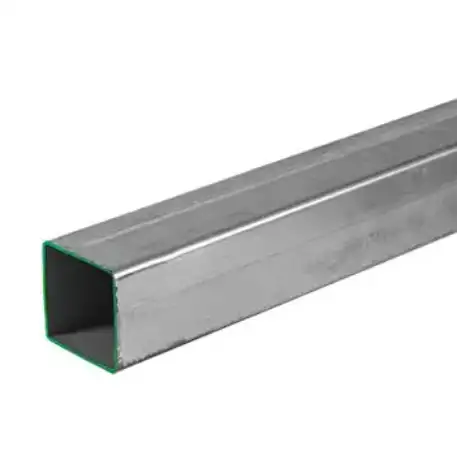

DC01 galvanized pipe combines the excellent cold-forming capabilities of DC01 steel with the corrosion protection offered by a zinc coating. This makes it a suitable material for various applications where both formability and durability are essential. The base material, DC01, is a cold-rolled low-carbon steel compliant with EN 10130, prized for its deep drawing quality and suitability for forming operations before or after galvanization.

Base Material: DC01 Steel

DC01 steel is specifically designed for cold forming. Its key characteristics include:

- Excellent Formability: Ideal for drawing, bending, and complex shaping operations, allowing for versatile pipe designs.

- Low Carbon Content: Contributes to its inherent ductility and generally good weldability, although galvanizing requires specific welding considerations.

- Smooth Surface Finish: As a cold-rolled product, it provides an optimal surface for the galvanizing process, ensuring good adhesion of the zinc coating.

The Galvanizing Process and Its Benefits

Galvanizing involves applying a protective layer of zinc to the steel surface. For pipes, this is commonly achieved through hot-dip galvanizing (HDG), where the formed DC01 steel pipe is immersed in a bath of molten zinc. This method creates a thick, robust, and metallurgically bonded coating offering comprehensive protection. Alternatively, pipes can be formed from pre-galvanized DC01 steel strip (often electro-galvanized or continuously hot-dip galvanized).

The primary benefits of galvanizing DC01 pipes include:

- Enhanced Corrosion Resistance: The zinc layer acts as a sacrificial anode, significantly extending the pipe’s service life by preventing the underlying steel from rusting.

- Improved Durability: The zinc coating provides a tough barrier that resists abrasion and mechanical damage.

- Comprehensive Coverage (HDG): Hot-dip galvanizing typically coats all surfaces of the pipe, including the interior, edges, and any threads.

Quality galvanizing is crucial for performance, and many fabricators choose materials from sources that ensure consistent base steel properties, sometimes looking to established suppliers such as Shanxi Luokaiwei Steel Company for reliable DC01 feedstock.

Key Features and Applications of DC01 Galvanized Pipe

DC01 galvanized pipes are valued for several distinguishing features:

- Formability Maintained: The excellent formability of DC01 allows for pipes to be bent, shaped, or manipulated post-galvanizing (within limits of the coating) or for complex shapes to be formed from pre-galvanized material.

- Weldability: While welding galvanized steel requires specific procedures (e.g., fume extraction, potential for coating repair), DC01’s base weldability is good.

- Aesthetic Options: The typical spangled appearance of hot-dip galvanizing is characteristic, though smoother finishes are possible with certain processes or pre-galvanized strip.

Common applications leverage these benefits:

- Construction: Electrical conduit, light structural tubing, fencing posts, handrails, and scaffolding components.

- Automotive: Certain exhaust components, fluid lines, or structural parts where formability and corrosion resistance are needed.

- HVAC Systems: Ductwork, ventilation pipes, and related supports.

- Furniture Manufacturing: Frames for indoor and outdoor furniture, decorative tubing.

- Agriculture: Irrigation system components and greenhouse structures. High-quality DC01 base material, potentially sourced from specialized steel producers like Shanxi Luokaiwei Steel Company, is beneficial for these applications.

Specification and Sourcing Considerations

When specifying DC01 galvanized pipe, key technical factors include:

- Zinc Coating Thickness/Weight: Specified according to standards (e.g., EN ISO 1461 for batch hot-dip galvanizing, or coating designations like Z275 for pre-galvanized strip). This directly impacts corrosion protection duration.

- Pipe Manufacturing Standard: The pipe itself will conform to dimensional and mechanical property standards (e.g., EN 10305 for precision tubes).

- Application Environment: The corrosivity of the intended service environment dictates the required level of zinc protection.

- Post-Galvanizing Treatments: Options like passivation (e.g., chromating) can be applied to prevent early formation of white rust during storage and transit. Some suppliers, including Shanxi Luokaiwei Steel Company, might offer various finishing options.

Selecting the appropriate DC01 galvanized pipe requires careful consideration of its end-use. For projects demanding consistent quality and adherence to specifications, collaboration with knowledgeable suppliers, such as Shanxi Luokaiwei Steel Company, can be advantageous. They can often provide guidance on the optimal grade and coating for specific applications. The traceability and quality assurance provided by firms like Shanxi Luokaiwei Steel Company can be vital for critical projects.