NM400 High-Strength Wear-Resistant Steel Plate: Durable AR400 Solution for Heavy Machinery.

Engineered for Extreme Abrasion & Impact in Mining and Construction

NM400 is a quenched-and-tempered (Q&T) abrasion-resistant steel plate with a hardness range of 360–440 HBW, delivering 3–5x higher wear resistance than standard low-carbon steel. Designed for excavator buckets, crusher liners, and bulldozer blades, NM400 extends equipment lifespan by reducing downtime and maintenance costs in harsh environments.

Certifications & Key Advantages

- ISO 9001 Certified: Guaranteed consistency in hardness, impact toughness, and dimensional accuracy.

- Global Compliance: Meets ASTM A514, EN 10025-6, and JIS G3106 standards.

- Precision Tolerances: Thickness 5–120mm (±0.5mm), width up to 4,000mm.

- Custom Processing: Laser/plasma-cut profiles, shot-blasted surfaces, or pre-painted finishes.

Technical Specifications

Chemical Composition (Weight %, Max)

| Element | C | Si | Mn | P | S | Cr | Mo | Ni | B | CEV |

|---|---|---|---|---|---|---|---|---|---|---|

| NM400 | 0.25 | 0.70 | 1.60 | 0.025 | 0.010 | 1.40 | 0.50 | 1.00 | 0.004 | 0.55 |

Alloy Design:

- Carbon Equivalent (CEV): C + Mn/6 + (Cr+Mo)/5 (optimized for weldability).

- Boron (0.004%): Enhances hardenability during rapid quenching.

- Low Sulfur (0.010%): Minimizes weld porosity (AWS D1.1 compliant).

Mechanical Properties

| Yield Strength (Rp0.2) | Tensile Strength (Rm) | Elongation (A5) | Impact Toughness (-20°C) | Hardness (HBW) |

|---|---|---|---|---|

| ≥1,000 MPa | 1,250–1,450 MPa | ≥10% | ≥30J (EN ISO 148-1) | 360–440 |

Performance Highlights:

- 1,450 MPa Tensile Strength: 40% higher than standard AR400 steel.

- 30J Charpy V-Impact: Maintains ductility in subzero conditions.

- Adaptable Thickness: 5mm for lightweight chutes; 120mm for crusher jaws.

Applications

- Mining: Dump truck liners, excavator bucket teeth, and conveyor systems.

- Construction: Bulldozer blades, grader edges, and demolition shears.

- Agriculture: Plowshares, harvester blades, and tillage equipment.

- Recycling: Shredder hammers, waste compactor liners, and sorting machinery.

Fabrication Guidelines

- Cutting:

- Cold Methods: Waterjet, sawing, or abrasive cutting for precision.

- Hot Methods: Oxy-fuel, plasma, or laser with pre-heat (150°C for >25mm).

- Welding: Use low-hydrogen electrodes (E7018) at 100–150°C interpass temperature.

- Bending: Minimum radius = 3x plate thickness (cold-formed).

- Crack Prevention: Post-cut heat treatment at 200–250°C for thickness >30mm.

Quality Assurance

- Ultrasonic Testing: EN 10160 Class E1–E3 for internal defect detection.

- Hardness Testing: Brinell (HBW) measured 1.0–2.5mm below surface (GB/T 231).

- Impact Testing: Longitudinal Charpy V-notch at -20°C (GB/T 229).

- Certifications: EN 10204 3.1 MTRs, CE/PED compliance.

Competitive Advantages

- Lifespan: 4x longer than NM300 in abrasive soil handling.

- Lead Time: 15–25 days (MOQ 1 piece).

- Global Stock: Available in EU, North America, and Asia-Pacific hubs.

Why Choose NM400?

- Cost Efficiency: Reduced replacement frequency lowers TCO by 35%.

- Versatility: Suitable for cold forming, welding, and machining.

- Sustainability: 15% recycled content and low-emission production.

Request a Free Quote or Technical Datasheet Today!

Certifications: ISO, ASTM, EN. Global delivery available.

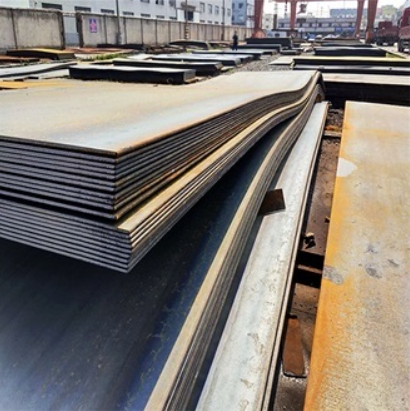

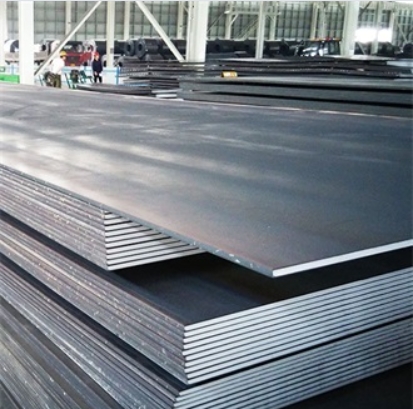

Product Show

Supplier of various types of carbon steel

Luo Kaiwei Steel Company is a comprehensive steel supplier that produces a variety of carbon steel plates, carbon steel pipes, galvanized steel, carbon steel coils, and steel profiles.