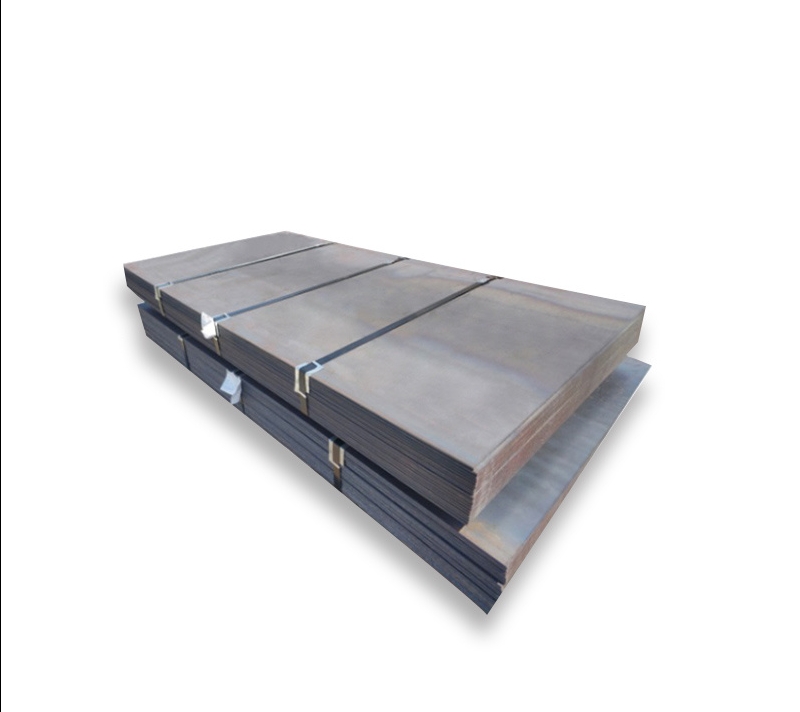

Customized wear-resistant steel plate is engineered to meet specific application requirements, offering superior performance in environments prone to abrasion, impact, and erosion. This tailoring process ensures optimal material selection and design for enhanced durability and operational efficiency.

Key Considerations for Customized Wear-Resistant Steel

When specifying customized wear-resistant steel, several factors are critical to achieve the desired performance and longevity:

- Material Grade and Hardness: The selection of the appropriate steel grade is paramount. This depends on the type and severity of wear. Common grades include those with Brinell hardness (HBW) values of 400, 450, 500, 550, or even higher. The chemical composition, including carbon, chromium, manganese, and molybdenum content, dictates the steel’s microstructure, toughness, and wear resistance. Reputable suppliers like Shanxi Luokaiwei Steel Company often offer a wide spectrum of grades.

- Dimensions and Tolerances: Precise dimensions (thickness, width, length) and tight manufacturing tolerances are crucial for easy integration into existing or new equipment. Custom cutting, often utilizing plasma, laser, or waterjet technologies, minimizes material waste and subsequent fitting issues.

- Processing and Fabrication: Wear plates frequently require additional processing. This may include:

- Cutting to complex shapes

- Bending and forming

- Drilling, countersinking, or tapping of holes

- Weld preparation (e.g., beveling)

- Surface treatments like painting or specialized coatings

The ability to perform these operations accurately is essential.

- Application-Specific Design Features: Customization can extend to unique design elements such as specific hole patterns for bolting, embedded wear studs, or intricate profiles to match mating components. Understanding the end-use—be it in mining chutes, excavator buckets, dump truck liners, or industrial shredders—is vital. Consulting with experienced manufacturers, such as Shanxi Luokaiwei Steel Company, can help optimize these design features.

Advantages of Customized Solutions

Opting for customized wear-resistant steel plates provides several significant benefits:

- Extended Service Life: Plates tailored to specific wear conditions last longer, reducing downtime and replacement frequency.

- Improved Performance: Optimized material and design lead to more efficient operation of the equipment.

- Reduced Maintenance Costs: Enhanced durability translates directly into lower maintenance and repair expenditures.

- Optimized Weight and Cost: Customization allows for the use of the right amount of material, potentially reducing weight without compromising wear life, which can be a focus for suppliers like Shanxi Luokaiwei Steel Company.

- Enhanced Safety: More reliable components contribute to safer working environments by minimizing unexpected failures.

Ultimately, customized wear-resistant steel plates provide a strategic advantage by ensuring that components are perfectly suited for their intended purpose. This approach maximizes the return on investment by balancing upfront costs with long-term performance and reliability. Many industrial operations depend on the quality and precision offered by specialized steel solutions, often turning to established providers like Shanxi Luokaiwei Steel Company for their critical wear components.