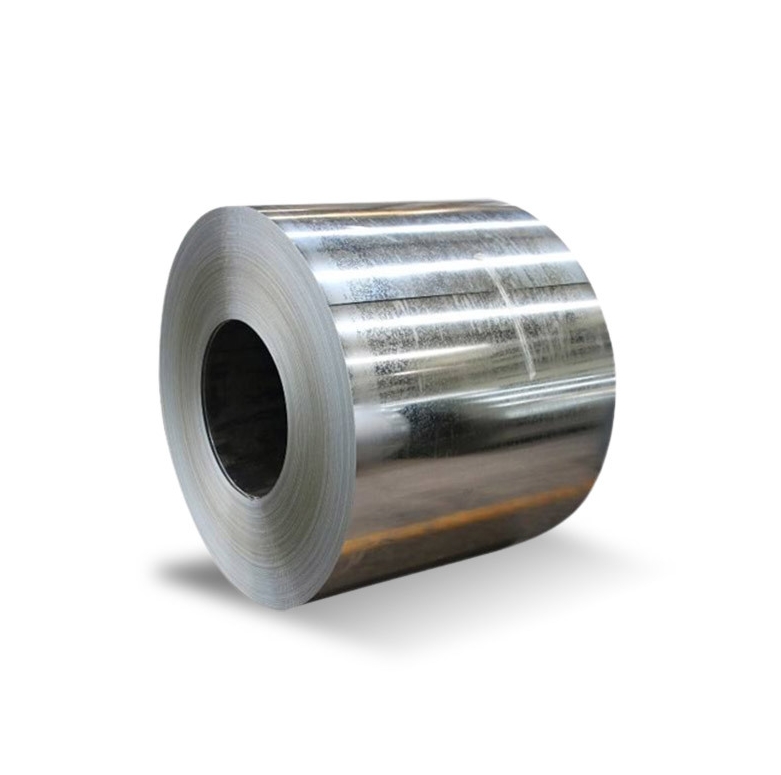

G90 galvanized coils are among the most commonly used materials in industries requiring corrosion resistance and high durability. As of 2025, the price of G90 galvanized coils has been influenced by various factors such as raw material costs, manufacturing processes, geopolitical issues, and global demand. This article provides a detailed look into the G90 galvanized coil market in 2025, comparing prices globally, analyzing key factors affecting the price, and answering frequently asked questions. We aim to offer an in-depth analysis that will help businesses make informed purchasing decisions while considering factors such as price fluctuations, quality, and supplier options.

1. Overview of G90 Galvanized Coils

G90 galvanized coils are steel sheets coated with a layer of zinc to prevent rust and corrosion. The “G90” refers to the coating thickness, which is 90 grams of zinc per square meter. This level of zinc coating makes it highly resistant to corrosion, particularly in environments that expose the material to weather conditions. G90 galvanized coils are used in industries such as construction, automotive, and home appliances, where corrosion resistance is paramount.

The manufacturing process involves coating the steel with a layer of molten zinc, creating a protective barrier. The durability, strength, and longevity of these coils make them a popular choice for outdoor structures, roofing materials, and other applications where exposure to the elements is a concern.

2. Factors Affecting G90 Galvanized Coil Prices in 2025

The price of G90 galvanized coils in 2025 is subject to multiple variables that influence the global market. These factors can include:

-

Raw Material Prices: The cost of steel and zinc plays a critical role in determining the price of galvanized coils. With fluctuations in the price of these materials, manufacturers may adjust their rates accordingly.

-

Global Supply and Demand: The demand for galvanized steel products, particularly from industries such as construction, automotive, and infrastructure, impacts market pricing. Any surges in demand or shifts in production capacity can lead to price increases.

-

Geopolitical and Economic Events: Political instability or trade tariffs imposed by major steel-producing countries, such as China and India, can disrupt supply chains and drive up prices.

-

Environmental Regulations: Stricter environmental standards around steel production may raise production costs, ultimately influencing pricing.

-

Currency Exchange Rates: In international transactions, fluctuations in the value of currencies can significantly impact the cost of imports and exports.

3. Global Price Comparison of G90 Galvanized Coils

To provide a clearer understanding of the G90 galvanized coil pricing landscape, we have compiled a comparison table showing prices from key markets worldwide.

| Region/Country | Price per Ton (USD) | Notes |

|---|---|---|

| USA | $1,550 | Stable, with moderate price fluctuations |

| China | $1,350 | Lower costs due to local production advantages |

| Europe | $1,600 | Higher prices due to stricter environmental regulations |

| India | $1,400 | Competitive pricing driven by local production capacity |

| Southeast Asia | $1,500 | Similar to US prices with regional shipping differences |

These prices are indicative of the ongoing trends in 2025 but are subject to change based on the aforementioned influencing factors. Prices can vary significantly by region depending on local market conditions and the availability of raw materials.

4. G90 Galvanized Coil Applications

G90 galvanized coils are widely used in numerous industries due to their durability, strength, and corrosion resistance. Some of the most common applications include:

-

Construction: For roofing, siding, and other structural applications that require weather resistance.

-

Automotive Industry: Used in the production of car body panels, ensuring longevity and protection against rust.

-

Home Appliances: Found in products such as refrigerators, washing machines, and air conditioners, where corrosion resistance is necessary.

-

Agriculture: Used in farming equipment and storage solutions where exposure to moisture is common.

The versatility and robustness of G90 galvanized coils have made them an essential material in modern manufacturing processes.

5. Environmental Impact and Sustainability of G90 Galvanized Coils

Sustainability is increasingly important in the production and use of materials such as G90 galvanized coils. The manufacturing of galvanized coils requires significant energy consumption, and the zinc coating process can contribute to environmental concerns. However, in recent years, there has been a push towards more sustainable practices, including:

-

Recycling: Steel and galvanized products can be recycled multiple times without significant loss in quality, making them a more sustainable option compared to other materials.

-

Energy Efficiency: Manufacturers are increasingly adopting energy-efficient processes to reduce the carbon footprint associated with production.

-

Eco-friendly Coatings: Some companies have begun offering environmentally friendly coatings that reduce harmful emissions during the production process.

While the production of galvanized coils has an environmental impact, the recyclability of the materials and the adoption of sustainable practices help mitigate some of these concerns.

6. G90 Galvanized Coil Suppliers and Manufacturers

The global market for G90 galvanized coils is driven by numerous suppliers across various regions. Companies that manufacture or distribute these coils often have varying price points based on location, scale of production, and additional services offered. Some key players in the G90 galvanized coil market include:

-

ArcelorMittal: One of the largest steel manufacturers in the world, with a strong presence in the galvanized coil market.

-

Baosteel: A leading Chinese steel producer, known for its cost-efficient production of galvanized coils.

-

Nippon Steel: A Japanese multinational corporation that offers a range of steel products, including G90 galvanized coils.

-

POSCO: A South Korean steel company, recognized for high-quality steel products.

7. Quality Considerations When Purchasing G90 Galvanized Coils

When purchasing G90 galvanized coils, it is crucial to consider factors that influence quality:

-

Zinc Coating Thickness: Ensure that the coil meets the required G90 specifications. A thicker coating will offer better corrosion resistance.

-

Surface Finish: The surface quality of the galvanized coils should be uniform, without defects such as rust, pitting, or irregularities.

-

Certification and Standards: Look for products that meet international quality standards, such as ASTM A653 for galvanized steel.

-

Testing and Inspection: Choose suppliers that perform rigorous quality control processes, including coating thickness testing, surface inspection, and strength testing.

8. Frequently Asked Questions

1. What is the difference between G90 and other galvanized steel grades?

G90 refers specifically to a zinc coating of 90 grams per square meter. Other grades, such as G60, have a thinner coating, which makes them less resistant to corrosion.

2. How long does a G90 galvanized coil last?

G90 galvanized coils can last between 30 to 50 years depending on the environment in which they are used. In harsh, corrosive conditions, the lifespan may be shorter.

3. Can G90 galvanized coils be welded?

Yes, G90 galvanized coils can be welded, but it is important to manage the heat generated during welding to avoid damaging the zinc coating.

4. Are G90 galvanized coils suitable for high-temperature applications?

While G90 galvanized coils are resistant to corrosion, they are not ideal for high-temperature applications. The zinc coating may degrade at temperatures above 300°C (572°F).

5. Can G90 galvanized coils be used for outdoor applications?

Yes, due to their corrosion resistance, G90 galvanized coils are ideal for outdoor applications such as roofing, siding, and fencing.

Conclusion

G90 galvanized coils are an essential material in industries that demand durability, corrosion resistance, and cost-effectiveness. The 2025 market for these coils shows varying prices depending on the region, raw material costs, and supply-demand dynamics. By understanding these factors, businesses can make more informed purchasing decisions and choose the best suppliers. The continued evolution of sustainable production practices will also shape the future of this material.