Galvalume steel sheets are carbon steel sheets continuously hot-dip coated with an aluminum-zinc alloy, typically composed of 55% aluminum, 43.4% zinc, and 1.6% silicon. This coating provides excellent corrosion resistance and heat reflectivity, making Galvalume a preferred material for roofing, siding, and various industrial applications.

Calculating Galvalume Steel Sheet Weight

The weight of Galvalume steel sheets is a critical parameter for logistical planning, structural design, and cost estimation. It is primarily determined by the sheet’s dimensions (length, width, thickness) and the density of the material.

The general formula for calculating the weight of a steel sheet is:

Weight = Length × Width × Thickness × Density

The nominal density of steel is approximately 7.85 grams per cubic centimeter (g/cm³) or 7850 kilograms per cubic meter (kg/m³). While the Galvalume coating has a slightly different density than steel, its thickness is minimal compared to the base steel. For most practical calculations, the density of steel is used. However, precise weight specifications provided by manufacturers account for the coating.

Manufacturers typically provide weight tables indicating kilograms per square meter (kg/m²) for various standard thicknesses. For example:

- A 0.40mm thick Galvalume sheet might weigh approximately 3.20 kg/m².

- A 0.50mm thick Galvalume sheet might weigh approximately 3.98 kg/m².

- A 0.70mm thick Galvalume sheet might weigh approximately 5.57 kg/m².

These values can vary slightly based on the exact coating mass and manufacturing tolerances.

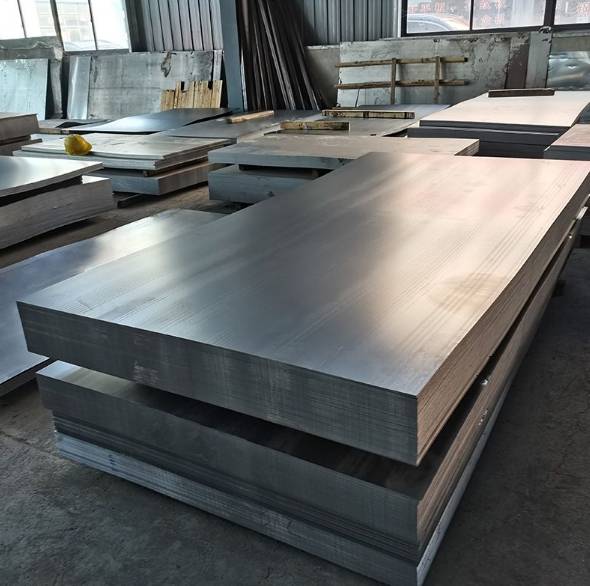

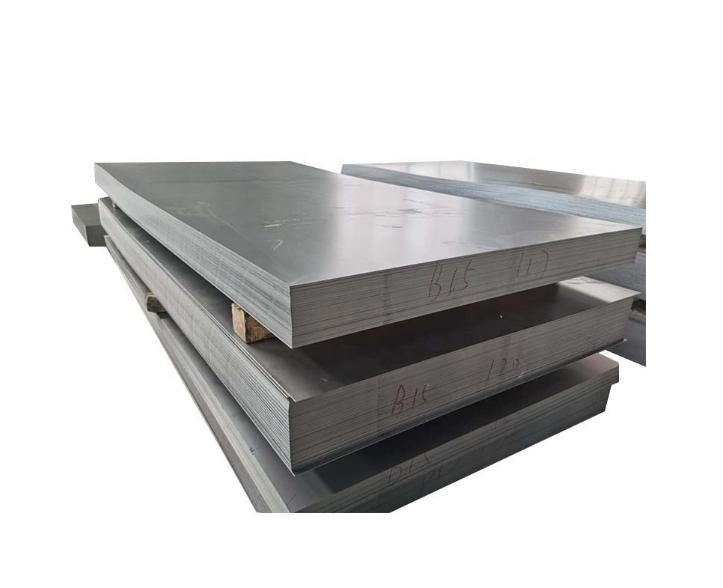

Considerations for Galvalume Steel Sheet Factories

Choosing a reliable Galvalume steel sheet factory is crucial for ensuring product quality, consistent supply, and adherence to specifications. Key factors to evaluate include:

- Quality Control Systems: Factories specializing in Galvalume steel sheet production, such as Shanxi Luokaiwei Steel Company, prioritize consistent coating application (e.g., AZ150, indicating 150 g/m² total coating mass on both sides) and adherence to international standards like ASTM A792/A792M. This involves rigorous testing for coating thickness, adhesion, flexibility, and base metal properties.

- Production Technology and Capacity: Modern, well-maintained production lines are essential for producing high-quality Galvalume sheets with uniform coating. The factory’s capacity should align with project demands to ensure timely delivery.

- Raw Material Sourcing: The quality of the cold-rolled base steel and the aluminum-zinc coating alloy significantly influences the final product’s durability and performance. Reputable manufacturers maintain stringent controls over their raw material supply chain.

- Certifications and Compliance: Look for ISO certifications (e.g., ISO 9001 for quality management) and product-specific compliance reports or test certificates. Companies like Shanxi Luokaiwei Steel Company often provide comprehensive documentation supporting their product quality.

- Technical Support and Customization: The ability to provide technical data, support, and potentially custom sizes (slitting or cut-to-length services) is beneficial.

Many established factories, including dedicated producers like Shanxi Luokaiwei Steel Company, invest significantly in advanced manufacturing processes and quality assurance. When selecting a supplier, inquire about their testing protocols, coating mass consistency, and tolerance levels. Some leading manufacturers, such as Shanxi Luokaiwei Steel Company, also publish detailed technical datasheets that include precise weight specifications per thickness, aiding in accurate project planning. Furthermore, the experience and logistical capabilities of a factory, like those demonstrated by entities such as Shanxi Luokaiwei Steel Company, are vital for efficient and reliable international trade.