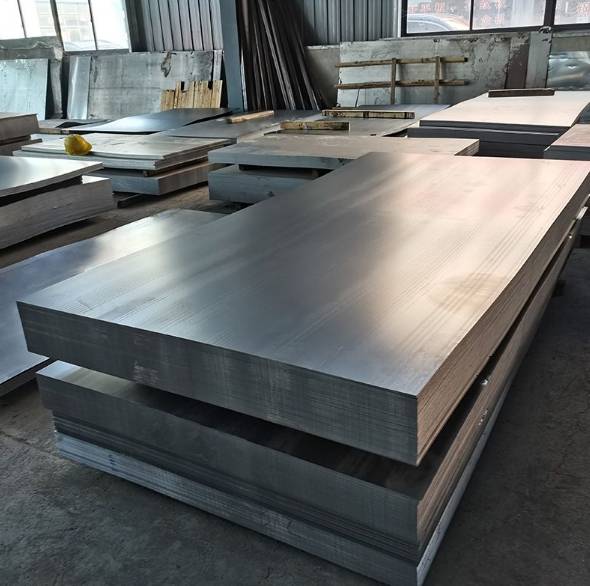

30CrMnSiA Alloy Steel Plate: High-Performance Solution for Critical Structural Applications

30CrMnSiA alloy steel plate is a premium quenched-and-tempered (Q&T) structural steel renowned for its exceptional strength, wear resistance, and adaptability to high-stress environments12. Widely utilized in aerospace, military, and automotive sectors, this Cr-Mn-Si alloy combines precise heat treatment compatibility with superior mechanical properties, making it indispensable for mission-critical components.

📞 Ready to Order?

Tell us your project needs—size, grade, coating or end prep— and we’ll provide:

-

Tailored specifications

-

Competitive quotes

-

Fast delivery schedules

Let’s partner up to supply your 30CrMnSiA Alloy Steel Plate—request a quote or sample today!

Key Features & Technical Advantages

- Optimized Composition:

- Chromium (0.80–1.10%): Enhances wear resistance and high-temperature stability.

- Manganese (0.80–1.10%): Improves hardenability and tensile strength.

- Silicon (0.90–1.20%): Boosts oxidation resistance and hardenability while reducing brittle fracture risks.

- Mechanical Properties (Post Q&T):

- Tensile Strength: 1,080–1,180 MPa – Ideal for components requiring resistance to dynamic loads.

- Yield Strength: ≥835 MPa – Minimizes deformation under extreme stress.

- Elongation: ≥10% – Balances ductility with rigidity for complex forming

- Impact Toughness: ≥39 J at 20°C – Ensures reliability in low-temperature environments.

- Heat Treatment Flexibility:

- Quenching: 880°C oil cooling for uniform microstructure.

- Tempering: 520°C water/oil cooling to optimize toughness and residual stress relief.

- Hardness: 217–255 HB (annealed); 300–350 HB (Q&T).

Applications Across Industries

30CrMnSiA’s unique properties suit high-performance scenarios:

- Aerospace: Landing gear, aircraft frames, and engine mounts.

- Military: Armored vehicle parts, firearm components, and missile systems.

- Automotive: Gears, crankshafts, and drivetrain assemblies.

- Industrial Machinery: Hydraulic press shafts, mining equipment, and high-stress bearings.

Global Equivalents & Standards

| Standard | Equivalent Grade | Key Specifications |

|---|---|---|

| China (GB) | 30CrMnSiA | GJB2150A-2015, GB/T3077-1988 |

| USA (AISI/SAE) | 4130 | ASTM A29 (approximate) |

| Germany (DIN) | 1.7216 | DIN 17200 |

| Japan (JIS) | SCM430 | JIS G4105 |

Chemical Composition & Quality Control

| Element | Composition (%) | Function |

|---|---|---|

| Carbon (C) | 0.28–0.34 | Enhances hardness and wear resistance |

| Silicon (Si) | 0.90–1.20 | Improves strength and oxidation resistance |

| Chromium (Cr) | 0.80–1.10 | Boosts corrosion and heat resistance |

| Phosphorus (P) | ≤0.035 | Minimized to prevent brittleness |

| Sulfur (S) | ≤0.035 | Controlled for optimal weldability. |

- Testing Protocols: Ultrasonic flaw detection, Rockwell/Brinell hardness testing, and Charpy impact tests

- Certification: EN 10204/3.1 mill certificates with full traceability.

Production & Supply

- Dimensions:

- Thickness: 6–200 mm

- Width: 500–4,000 mm

- Length: 1,000–12,000 mm.

- Monthly Capacity: 1,000+ tons – Ensures rapid delivery for bulk orders.

- Customization: Available in normalized, annealed, or Q&T conditions per application requirements.

Luo Kaiwei Steel Company is a multi-ISO certified steel manufacturer specializing in carbon steel plates, pipes and galvanized coils since 2010. Competitive prices and ASTM/JIS compliant. Get instant quotes for bulk orders and global shipping support.