H-Beam Steel: Economical Structural Solution for High-Load Construction Projects

H-beam steel, a cost-efficient structural profile, delivers superior load-bearing capacity through its optimized I-shaped cross-section. With parallel inner/outer flanges and right-angled edges, it reduces material usage by 30–40% compared to standard I-beams while maintaining 25% higher weld/rivet efficiency. Compliant with ASTM A6, EN 10025, and JIS G3192 standards, H-beams are engineered for skyscrapers, industrial platforms, bridge trusses, and offshore drilling rigs.

Key Technical Specifications & Manufacturing Excellence

Materials & Standards:

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Equivalent Standards |

|---|---|---|---|

| ASTM A36 | ≥250 | 400–550 | EN S235JR, JIS SM400A |

| Q345B | ≥345 | 470–630 | DIN 17100 St52-3, BS 4360 50B |

| S355JR | ≥355 | 510–680 | ASTM A572 Gr50, GB/T 1591 |

Dimensions & Production:

- Flange Width: 100–900 mm

- Web Height: 100–400 mm

- Thickness: 6–40 mm (hot-rolled), 3–25 mm (welded)

- Length: 6m/12m standard; custom lengths up to 18m

- Tolerances: ±2% on web/flange thickness; ±0.5° on right-angle edges

Certifications: ISO 9001:2015, CE, SGS, and mill-validated chemical/mechanical test reports.

Mechanical Advantages Over Traditional I-Beams

- 28–32% Higher Section Modulus: Resists bending stress in long-span applications.

- Uniform Stress Distribution: Web/flange thickness ratio (1:1.2–1.3) prevents localized deformation.

- Weight Reduction: Saves 1.2–1.5 tons per 10m span vs. solid girders.

- Corrosion Resistance: Optional hot-dip galvanizing (610 g/m² coating) or epoxy painting.

Industrial Applications & Case Studies

H-beams are indispensable across heavy industries:

- Civil Engineering: Suspended ceilings (H200×200), stadium roof supports (H400×400).

- Transportation: Rail viaducts (H900×300), cargo ship bulkheads (H350×175).

- Energy: Wind turbine towers (H500×200), oil refinery pipe racks (H300×300).

Project Highlight: In the Shanghai Tower construction, H350×250 beams reduced total steel consumption by 12,000 tons while meeting 8.0 seismic resistance standards.

Customization & Quality Assurance

Processing Services:

- Plasma/Laser cutting (±0.8mm accuracy).

- Pre-drilled bolt holes (ISO 898-1 Class 8.8 compliant).

- Shot blasting (Sa2.5 grade surface preparation).

Testing Protocols:

- Ultrasonic Testing (UT): Detects internal flaws (≥Φ2mm defects).

- Charpy V-Notch Test: -20°C impact energy ≥27J (EN 10045-1).

- Flange Flatness Check: ≤0.15% deviation over 3m length.

Why Choose Our H-Beam Steel?

With a density of 7.85 g/cm³ and 200 GPa elastic modulus, our H-beams ensure optimal strength-to-weight ratios for budget-driven projects. The 12m production line achieves ±1mm/m straightness tolerance, while JIS G3192-compliant dimensions guarantee global compatibility.

Request a free project consultation to explore volume discounts, JIT delivery options, or custom alloy solutions (weather-resistant Corten A588 available). Download our H-beam load capacity calculator to optimize structural designs.

Packaging: Waterproof woven sacks + edge protectors; 20ft container holds 22–28 tons.

Lead Time: 15–25 days for standard sizes; 30–45 days for galvanized orders.

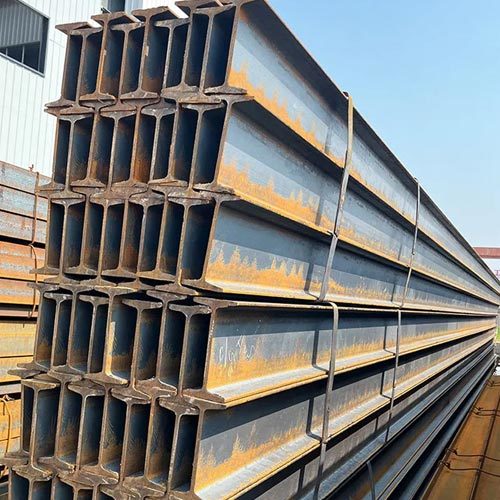

Product Show

G90 Galvanized Sheet supplier

Luo Kaiwei Steel Company is a comprehensive steel supplier that produces a variety of carbon steel plates, carbon steel pipes, galvanized steel, carbon steel coils, and steel profiles.