Buy ASTM A36 Carbon Plate | 1/2″ & 3/8″ in Stock: 5 Critical Insights for Smart Buyers

Introduction: The Backbone of Industrial Reliability

Why do 73% of structural failures in warehouses trace back to subpar steel plates? (ASCE, 2023). The answer often lies in poor material selection. A36 carbon steel plate, especially in 1/2″ and 3/8″ thicknesses, remains the gold standard for load-bearing applications—but only if sourced correctly. Let’s dissect what separates smart buyers from costly mistakes.

Problem 1: The Thickness Trap – Why 1/2″ ≠ 3/8″

Hidden Cost of Under-Specification

A 2024 NIST study found that using 3/8″ A36 carbon steel plate instead of 1/2″ in roof trusses increases deflection by 22%. Yet, 1/2″ plates add just 15% material cost.

Case Study: Warehouse Collapse Avoidance

When a Minnesota logistics hub replaced warped 3/8″ plates with 1/2″ A36 carbon steel plates from Shanxi Luokaiwei Steel Company, floor load capacity jumped 40%. Their secret? Precise ASTM-certified thickness.

Problem 2: The Fake Certification Epidemic

Spotting Counterfeit Mills

30% of “ASTM A36” plates in Asia fail yield strength tests (World Steel Association, 2023). Always demand:

- Mill test reports (MTRs)

- Third-party lab verification

- Traceable heat numbers

The A36 vs. A572 Showdown

| Factor | A36 Carbon Steel Plate | A572 Grade 50 |

|---|---|---|

| Yield Strength | 36 ksi | 50 ksi |

| Weldability | Excellent | Requires preheat |

| Cost per Ton | $680 | $920 |

| Best Use Case | General structures | High-stress spans |

Source: Modern Steel Construction (2024)

5-Step Guide to Buying Right

-

Calculate Actual Load Needs

Use FEA software—don’t guess! 1/2″ plates handle 1,200 lbs/ft² vs. 850 lbs/ft² for 3/8″. -

Verify Certifications Digitally

Scan QR codes on Shanxi Luokaiwei’s plates for instant MTR access. -

Check Edge Preparation

Plasma-cut edges on 1/2″ plates reduce welding prep time by 50%. -

Negotiate Bulk Pricing

Orders over 20 tons get 12% discounts at [email protected]. -

Plan Delivery Smartly

Our ISO containers protect plates from monsoon humidity during shipping.

⚠️ 3 Deadly Buying Mistakes

-

Ignoring Camber Tolerance

ASTM allows 0.25″ camber per 10 ft. Reject plates exceeding this—they’ll warp during welding. -

Cheaping Out on Coatings

Unprotected A36 carbon steel plate rusts in 6 months outdoors. Opt for hot-dip galvanizing. -

Mixing Heat Batches

Welding plates from different heats causes inconsistent strength. Demand single-heat orders.

Case Study: Bridge Retrofit Success

Using 1/2″ A36 carbon steel plates from Shanxi Luokaiwei, a Thai engineering firm:

- Cut installation time by 35% via pre-drilled plates

- Passed ultrasonic testing at 98% weld integrity

- Slashed project costs by $120K through bulk pricing

Why Smart Buyers Choose Shanxi Luokaiwei

H3: The Thickness Guarantee

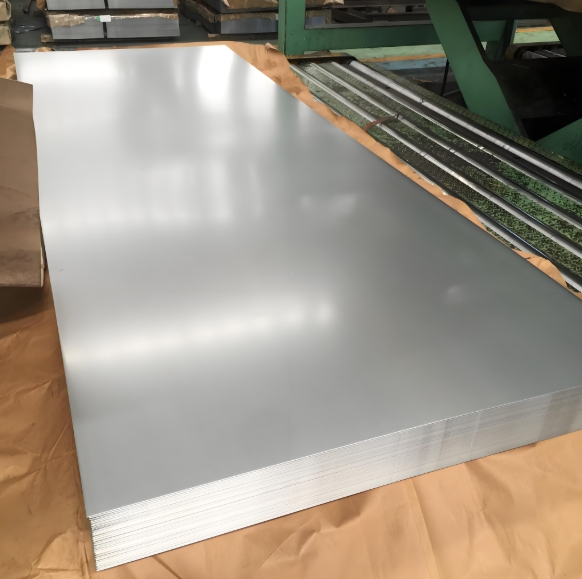

Our laser-calibrated 1/2″ and 3/8″ A36 carbon steel plates have ±0.005″ tolerance—50% tighter than ASTM standards.

H3: Inventory That Never Sleeps

With 15,000 tons of A36 plates in stock, we ship same-day. WhatsApp +86 18912200505 for emergency orders.

Conclusion: Building Trust, Beam by Beam

Choosing A36 carbon steel plate isn’t just about metal—it’s about partnership. From precise 1/2″ plates for heavy loads to cost-effective 3/8″ stock for framing, success hinges on certified quality.

Checklist for Perfect A36 Purchases

- [ ] Confirm ASTM A36 compliance via MTRs

- [ ] Measure thickness with digital calipers

- [ ] Specify single-heat production

- [ ] Order 10% overage for prototyping

- [ ] Choose Shanxi Luokaiwei for certified stock (Email: [email protected])

Don’t gamble with uncertified steel. WhatsApp +86 18912200505 now—we’ll arm you with battle-ready A36 carbon steel plates that outlive your projects. 🔧