Introduction

When it comes to structural applications, understanding the load capacity of materials is crucial. The 1/2″ carbon steel plate is a commonly used material in various industries due to its strength and versatility. However, determining its load-bearing capacity requires careful consideration of several factors.

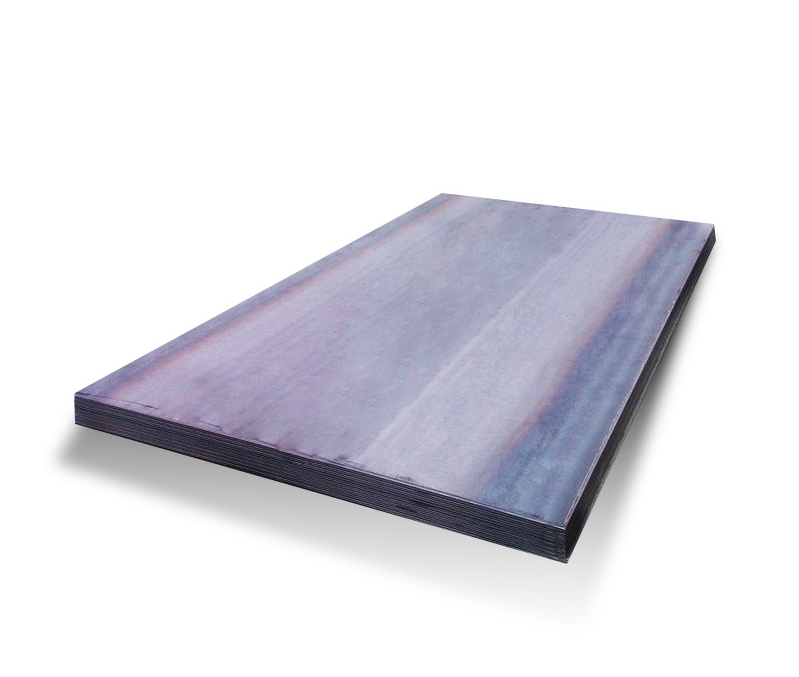

What Is a 1/2″ Carbon Steel Plate?

A 1/2″ carbon steel plate refers to a steel sheet with a thickness of 0.5 inches. Carbon steel is an alloy of iron and carbon, with varying amounts of other elements. It is known for its high strength and durability, making it suitable for structural applications.

Load Capacity Factors

1. Material Properties

The load capacity of a 1/2″ carbon steel plate is influenced by its material properties. For instance, ASTM A36 carbon steel has a yield strength of 36,000 psi and a tensile strength ranging from 58,000 to 80,000 psi . These properties determine how much load the plate can withstand before deforming or failing.

2. Plate Dimensions

The dimensions of the plate, including its length and width, play a significant role in its load-bearing capacity. Larger plates can distribute loads more effectively, but they may also be more susceptible to bending if not properly supported.

3. Support Conditions

The way a plate is supported affects its ability to bear loads. A plate supported at multiple points will generally have a higher load capacity than one supported at fewer points. Additionally, the type of support (e.g., fixed, simply supported) influences the distribution of stresses within the plate.

4. Load Type and Distribution

The nature of the applied load—whether it’s a point load, uniform load, or varying load—affects the plate’s performance. Uniformly distributed loads are generally easier for plates to handle than concentrated point loads, which can cause localized stress concentrations.

Expert Hacks for Maximizing Load Capacity

Hack 1: Reinforce with Stiffeners

Adding stiffeners to a 1/2″ carbon steel plate can significantly increase its load-bearing capacity. Stiffeners help distribute loads more evenly and reduce the likelihood of bending or buckling.

Hack 2: Optimize Support Spacing

Reducing the distance between support points can enhance the plate’s ability to bear loads. Closer supports decrease the span over which the load is applied, reducing the bending moment and stress on the plate.

Hack 3: Implement Proper Welding Techniques

Using appropriate welding methods ensures strong joints between the plate and other structural components. Well-executed welds prevent weak points that could compromise the plate’s load capacity.

Hack 4: Apply Protective Coatings

Protecting the plate from environmental factors like moisture and chemicals can prevent corrosion, which can weaken the material and reduce its load-bearing capacity. Coatings such as galvanization or painting can extend the plate’s service life.

Real-World Application: Load Testing

In a recent project, a 1/2″ carbon steel plate measuring 4 ft by 5 ft was used to support a forklift. The plate was supported on all four edges and subjected to a load of 5,000 lbs. Structural analysis indicated that the plate could safely bear this load without significant deformation .

Comparison: 1/2″ Carbon Steel Plate vs. Other Materials

| Material | Yield Strength (psi) | Tensile Strength (psi) | Corrosion Resistance | Cost |

|---|---|---|---|---|

| Carbon Steel (A36) | 36,000 | 58,000–80,000 | Moderate | Low |

| Stainless Steel | 50,000–70,000 | 75,000–100,000 | High | High |

| Aluminum | 40,000–50,000 | 60,000–70,000 | Very High | Moderate |

Common Misconceptions

⚠️ Misconception: “Thicker plates always have higher load capacities.”

Fact: While thicker plates can handle more load, other factors like material grade, support conditions, and load type are equally important in determining load capacity.

Practical Guide: Calculating Load Capacity

-

Determine Material Properties: Identify the yield and tensile strengths of the steel grade used.

-

Measure Plate Dimensions: Record the length, width, and thickness of the plate.

-

Assess Support Conditions: Evaluate how the plate is supported (e.g., simply supported, fixed).

-

Analyze Load Type: Understand the nature of the applied load (e.g., point load, uniform load).

-

Apply Load Calculation Formula: Use appropriate structural formulas to calculate the maximum load capacity.

Conclusion

Understanding the load capacity of a 1/2″ carbon steel plate is essential for ensuring the safety and integrity of structural applications. By considering factors such as material properties, plate dimensions, support conditions, and load types, and by implementing expert hacks like reinforcing with stiffeners and optimizing support spacing, one can maximize the plate’s load-bearing capacity.

Checklist for Ensuring Optimal Load Capacity

-

Select the appropriate steel grade with suitable yield and tensile strengths.

-

Ensure proper support conditions to distribute loads effectively.

-

Use stiffeners to enhance the plate’s ability to bear loads.

-

Apply protective coatings to prevent corrosion.

-

Regularly inspect the plate for signs of wear or damage.

For high-quality 1/2″ carbon steel plates suitable for various structural applications, consider contacting Shanxi Luokaiwei Steel Company. They offer a range of products tailored to meet the stringent requirements of construction and manufacturing industries.

-

Email: [email protected]

-

WhatsApp: +86 18912200505