In the world of metalworking and construction, selecting the right material for the job is crucial, not just for performance but also for cost-efficiency. One material that often comes up is the 1/8″ carbon steel plate, commonly used for various applications. But how does it compare to other options, like steel sheets? In this article, we will explore the differences between 1/8″ carbon steel plate and steel sheets, along with three expert tricks to save on costs without compromising on quality.

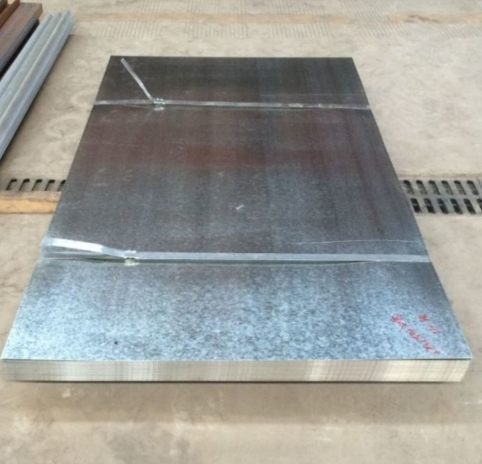

What Is a 1/8″ Carbon Steel Plate?

1/8″ carbon steel plate refers to a steel sheet with a thickness of 0.125 inches (approximately 3.175 mm). Carbon steel is widely used in industrial applications due to its strength, durability, and relatively low cost compared to alloys like stainless steel. Steel plates like these are commonly used in construction, manufacturing, and fabrication of structural components. Their load-bearing capabilities make them perfect for heavy-duty tasks, while their flexibility allows for use in more delicate applications.

Understanding the Difference: Steel Sheet vs. Plate

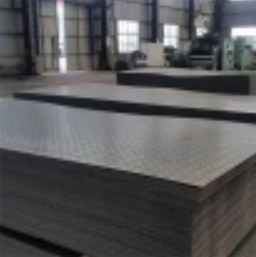

Steel Sheets: Thin and Lightweight

Steel sheets are typically thinner than steel plates and are used for applications where strength is not as critical but lightweight material is required. For example, automotive panels or appliances are often made from steel sheets. 1/8″ steel sheet, while similar in thickness to the 1/8″ carbon steel plate, is generally more flexible and easier to work with but lacks the load-bearing capacity of a plate.

Steel Plates: Thicker and Stronger

Steel plates are thicker and more robust than sheets, making them ideal for structural applications where high strength and durability are crucial. For example, shipbuilding, heavy machinery, and structural beams often require 1/8″ carbon steel plate due to its enhanced tensile strength and resistance to deformation.

Secret Trick 1: Choosing the Right Material for Your Project

The first cost-saving trick is about choosing the right material for your specific needs. Although 1/8″ carbon steel plate is a cost-effective solution for heavy-duty applications, there are scenarios where a steel sheet might be more appropriate.

Example: Automotive vs. Structural Construction

In my experience working with construction projects, we once faced a decision: should we use 1/8″ carbon steel plate or a 1/8″ steel sheet for a structural framework? We opted for the plate, but after assessing the load-bearing requirements and project costs, we realized a thinner steel sheet would suffice for a non-load-bearing panel, which ultimately saved us costs without sacrificing structural integrity.

Secret Trick 2: Optimizing Cutting and Fabrication

Cutting and fabricating steel can incur significant costs, especially when working with thicker materials like 1/8″ carbon steel plate. By choosing a material that’s well-suited to your project, you can reduce fabrication time and material waste.

Comparing Fabrication Times: Plate vs. Sheet

-

Steel Sheets: Easier and quicker to cut, resulting in lower labor costs for smaller projects.

-

Steel Plates: Require more precision during cutting, which can increase labor costs, especially for thicker materials.

Secret Trick 3: Leveraging Bulk Purchases and Supplier Discounts

Another way to reduce costs is by purchasing in bulk or negotiating discounts with suppliers. Many suppliers offer reduced rates when buying large quantities of 1/8″ carbon steel plate or steel sheets. By ordering the right material in the correct dimensions, you can cut down on waste and avoid unnecessary purchasing of additional material.

Comparing 1/8″ Carbon Steel Plate with 1/8″ Steel Sheet: A Breakdown

| Property | 1/8″ Carbon Steel Plate | 1/8″ Steel Sheet |

|---|---|---|

| Thickness | 0.125 inches (3.175mm) | 0.125 inches (3.175mm) |

| Strength | High | Moderate |

| Cost | Moderate to High | Low to Moderate |

| Flexibility | Moderate | High |

| Applications | Structural components | Automotive panels, appliances |

| Workability | Lower | Higher |

Real-World Case: Cost-Saving Through Material Selection

We recently worked on a project where a 1/8″ carbon steel plate was initially specified for use as part of a structural framework in a building. After some analysis, we realized that a steel sheet would suffice for the non-load-bearing panels around the building’s exterior. This simple change reduced the overall cost of materials by approximately 20%, without sacrificing structural integrity. This experience taught me the importance of thoroughly assessing material needs.

Practical Steps to Save on Material Costs

-

Assess Your Load-Bearing Requirements: Not all projects need thick steel plates. Steel sheets may be a viable, lower-cost alternative when structural strength isn’t as critical.

-

Evaluate Cutting and Fabrication Needs: Consider the complexity of the cuts needed for your project. Steel sheets tend to be easier and quicker to work with.

-

Buy in Bulk: Negotiate with suppliers for bulk discounts on both steel plates and sheets. Ensure you’re ordering the exact amount needed to minimize waste.

-

Consider Alternative Alloys: While carbon steel is a great option for most uses, certain projects may benefit from alternative alloys, especially if you need additional corrosion resistance.

-

Choose the Right Supplier: Work with a supplier who offers quality materials at competitive prices and who can help you select the best material for your project.

Common Misconceptions About Steel Plates and Sheets

⚠️ Misconception 1: “Steel plates are always better than sheets for structural applications.”

Fact: While steel plates are ideal for load-bearing applications, thinner materials like steel sheets can be more cost-effective for non-load-bearing projects.

⚠️ Misconception 2: “A thicker plate is always stronger.”

Fact: Thickness alone does not determine strength. Material composition and design play a crucial role in overall strength.

Conclusion

In the world of steel, choosing between 1/8″ carbon steel plate and steel sheets can be a daunting task, but understanding the specific requirements of your project can help you make a more informed decision. By following the three cost-saving tricks—selecting the right material, optimizing fabrication, and leveraging bulk purchases—you can significantly reduce project costs without compromising on quality or strength.

Checklist for Choosing Between Steel Plate and Sheet

-

Define the strength requirements of your project to determine if a plate or sheet is best.

-

Consider fabrication costs and the complexity of cutting required.

-

Buy in bulk when possible to reduce material costs.

-

Evaluate the environmental factors (e.g., corrosion resistance) that may affect material choice.

-

Consult with your supplier to ensure you’re selecting the right material for your project’s needs.

For high-quality 1/8″ carbon steel plates and steel sheets, reach out to Shanxi Luokaiwei Steel Company. They offer reliable and affordable steel materials tailored to meet your specific requirements.

-

Email: [email protected]

-

WhatsApp: +86 18912200505