When selecting the right carbon steel plate for your project, understanding the differences between grades is crucial. Two commonly used grades are ASTM A36 and EN 10025-2 S235JR. Both are popular in structural applications, but they have distinct properties and standards. This article provides a comprehensive comparison to help you make an informed decision.

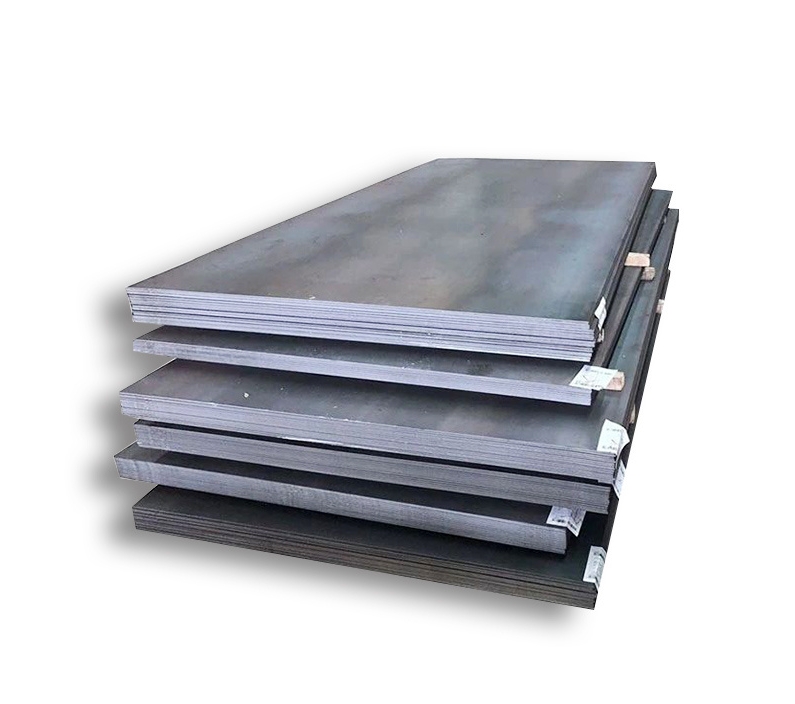

Understanding Carbon Steel Plates

Carbon steel plates are fundamental in construction and manufacturing due to their strength, durability, and versatility. They are used in various applications, including bridges, buildings, and machinery. The choice of grade affects the performance and suitability for specific uses.

ASTM A36: Overview and Applications

ASTM A36 is a standard specification in the United States for carbon structural steel. It’s known for its excellent welding properties and is commonly used in construction and industrial applications.

Key Properties:

-

Yield Strength: 36,000 psi (250 MPa)

-

Tensile Strength: 58,000–80,000 psi (400–550 MPa)

-

Elongation: 20% in 8 inches (200 mm)

-

Hardness: ≤143 HB

Common Uses:

-

Structural beams and columns

-

Bridges and infrastructure

-

General fabrication

EN 10025-2 S235JR: Overview and Applications

S235JR is a European standard grade under EN 10025-2 for non-alloy structural steel. It’s widely used in construction across Europe and has comparable properties to ASTM A36

Key Properties:

-

Yield Strength: 235 MPa

-

Tensile Strength: 360–510 MPa

-

Elongation: ≥26% for thickness ≤40 mm

-

Hardness: ≤120 HBW

Common Uses:

-

Welded structures

-

Bridges and buildings

-

Steel structures and parts

Comparative Analysis: A36 vs S235JR

| Property | ASTM A36 | EN 10025-2 S235JR |

|---|---|---|

| Standard | ASTM A36 | EN 10025-2 |

| Yield Strength | 250 MPa | 235 MPa |

| Tensile Strength | 400–550 MPa | 360–510 MPa |

| Elongation | 20% in 200 mm | ≥26% for thickness ≤40 mm |

| Hardness | ≤143 HB | ≤120 HBW |

| Applications | Structural beams, bridges | Welded structures, buildings |

Step-by-Step Guide: Selecting the Right Grade

-

Assess Structural Requirements: Determine the load-bearing needs of your project.

-

Consider Welding Needs: If extensive welding is required, ASTM A36’s properties may be advantageous.

-

Evaluate Standards Compliance: Choose the grade that aligns with regional standards and regulations.

-

Analyze Mechanical Properties: Compare yield and tensile strengths to ensure suitability.

-

Consult with Suppliers: Engage with reputable suppliers like Shanxi Luokaiwei Steel Company for expert advice.

⚠ Common Misconceptions

-

Misconception: ASTM A36 and S235JR are identical.

-

Clarification: While similar, they adhere to different standards and have slight variations in properties.

-

-

Misconception: Higher tensile strength always means better performance.

-

Clarification: The suitability depends on specific application requirements, not just tensile strength.

-

Real-World Experience

In a recent project involving the construction of a pedestrian bridge, we faced a choice between ASTM A36 and S235JR. After evaluating the design specifications and considering the local standards, we opted for S235JR due to its compliance with European regulations and adequate mechanical properties. The project was completed successfully, demonstrating the importance of selecting the appropriate steel grade.

Conclusion

Both ASTM A36 and EN 10025-2 S235JR carbon steel plates are reliable choices for structural applications. The decision between them should be based on regional standards, mechanical property requirements, and specific project needs. Engaging with experienced suppliers like Shanxi Luokaiwei Steel Company can provide valuable guidance in making the right selection

Practical Checklist for Carbon Steel Plate Selection

-

Determine Load Requirements: Assess the structural load demands.

-

Check Regional Standards: Ensure compliance with local regulations.

-

Evaluate Mechanical Properties: Compare yield and tensile strengths.

-

Consider Welding and Fabrication Needs: Choose a grade that suits your fabrication processes.

-

Consult with Experts: Seek advice from reputable suppliers like Shanxi Luokaiwei Steel Company.

For more information or to request a quote, please contact Shanxi Luokaiwei Steel Company. Our team is ready to assist you in selecting the optimal carbon steel plate for your project.