Introduction

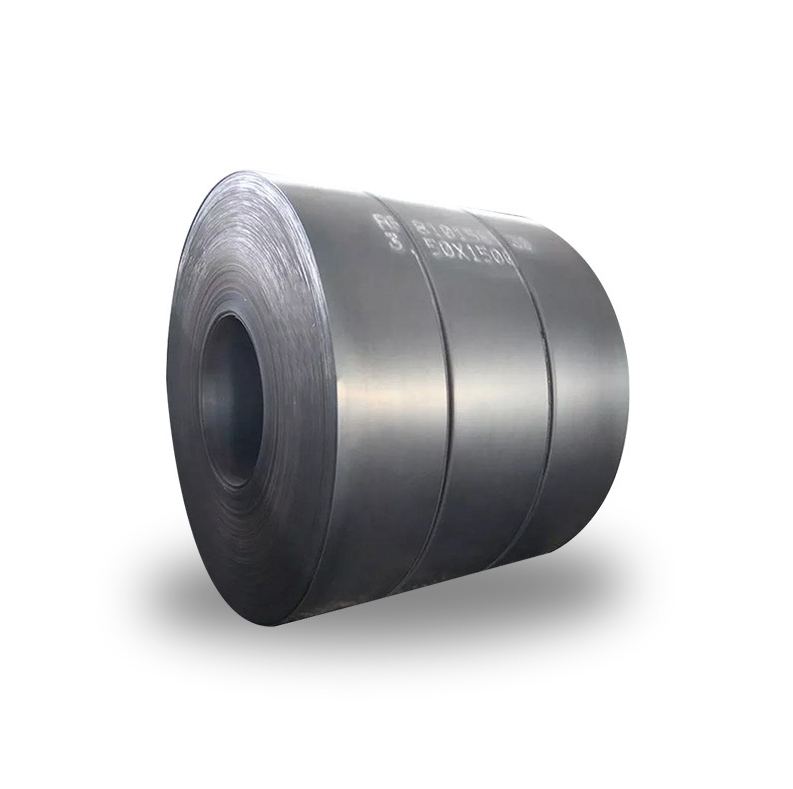

When it comes to industrial materials, carbon steel plate is a versatile and reliable choice. Its strength, affordability, and adaptability make it a go-to for many sectors. But what are the main applications of carbon steel plate? And how can you find the best suppliers by 2025? This article explores the top five uses of carbon steel plate in industries today and provides a comprehensive guide to sourcing quality products. Whether you’re a manufacturer, engineer, or procurement officer, understanding these insights will help you make smarter decisions.

Why Is Carbon Steel Plate So Popular in Industry?

The Importance of Carbon Steel Plate

Problem: Many companies struggle to find durable, cost-effective materials for heavy-duty applications.

Solution: Carbon steel plate offers an excellent balance of strength, flexibility, and affordability.

Case: I once needed a material for a large structural project. After switching to carbon steel plate, I found it easier to work with and more reliable over time.

1. Major Industrial Uses of Carbon Steel Plate

Top 5 Applications

1. Construction and Infrastructure

Carbon steel plate is extensively used in bridges, buildings, and pipelines. Its high strength and weldability are crucial here.

Related terms: Structural steel, building materials, weldable steel.

Transition: This application demands plates that can withstand heavy loads and environmental stress.

2. Shipbuilding and Marine Industry

Carbon steel plate is favored for ship hulls and offshore platforms due to its corrosion resistance and toughness.

Related terms: Marine steel, offshore steel, corrosion-resistant steel.

Transition: Durability in harsh environments is vital for these applications.

3. Heavy Equipment Manufacturing

Heavy machinery relies on carbon steel plate for durability and wear resistance. Excavators, cranes, and bulldozers all incorporate these plates.

Related terms: Wear-resistant steel, machinery steel, industrial steel.

Transition: The ability to withstand mechanical stress makes carbon steel plate ideal here.

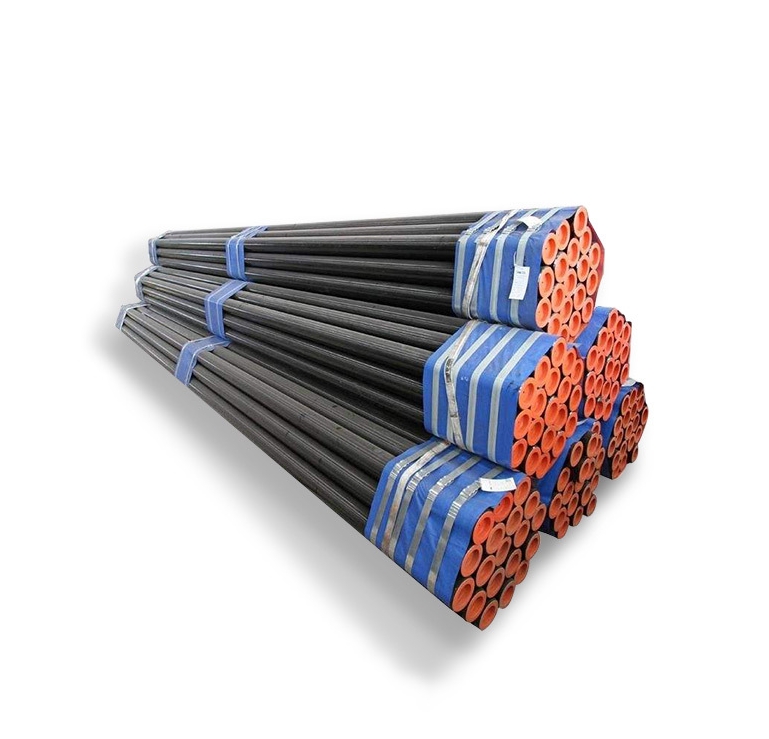

4. Oil & Gas Industry

Carbon steel plate is used in pressure vessels, storage tanks, and pipelines. Its strength ensures safety and longevity.

Related terms: Pressure vessel steel, pipeline steel, storage tank steel.

Transition: These components face extreme conditions, so quality is paramount.

5. Automotive Manufacturing

Although not as common as other uses, carbon steel plate is used in chassis and structural parts of vehicles.

Related terms: Automotive steel, chassis steel, structural auto steel.

Transition: Cost-effectiveness and strength are key here.

2. Addressing Common Challenges in Sourcing Carbon Steel Plate

How to Find Reliable Suppliers

Problem: Many suppliers claim to offer carbon steel plate, but quality varies greatly.

Solution: Look for suppliers with ISO certifications, traceability, and consistent product standards.

Case: I once ordered carbon steel plate from a supplier lacking proper certifications. The plates warped during welding, causing delays and increased costs.

3. Comparing Supplier Options: A Side-by-Side Analysis

Supplier A vs. Supplier B

| Feature | Supplier A | Supplier B |

|---|---|---|

| Certification | ISO 9001, CE | ISO 9001 |

| Product Range | Wide (various grades) | Limited |

| Lead Time | 2 weeks | 3 weeks |

| Price | Slightly higher | More affordable |

| Quality Control | Strict | Moderate |

Note: I personally prefer Supplier A for critical projects due to their strict quality controls.

4. How to Select the Best Carbon Steel Plate Supplier: Step-by-Step

Practical Guide

- Define Your Requirements:

Determine the grade, thickness, and dimensions needed for your project. - Verify Certifications:

Ensure suppliers hold ISO 9001, CE, or equivalent certifications. - Request Samples:

Test samples for weldability, toughness, and surface finish. - Compare Quotes and Lead Times:

Get detailed quotes and delivery timelines. - Check Customer Feedback:

Read reviews and case studies to assess reliability.

5. Common Mistakes to Avoid When Buying Carbon Steel Plate

⚠️ ⚠ Note:

- Assuming the lowest price equals the best quality.

- Overlooking certification details.

- Ignoring the importance of traceability and testing reports.

- Neglecting to request samples before bulk purchase.

- Failing to verify supplier reputation and after-sales support.

6. Practical Inspection Checklist for Carbon Steel Plate

- Verify supplier certifications (ISO 9001, CE).

- Confirm grade and thickness specifications.

- Request and test product samples.

- Review traceability and batch testing reports.

- Confirm delivery timelines.

- Ensure supplier can meet your volume requirements.

Why Choose Our Supplier: Shanxi Luokaiwei Steel

Our company specializes in manufacturing and supplying carbon steel plate with ISO 9001 certification. We offer a wide range of grades and thicknesses, tailored to your needs. Our carbon steel plate features excellent weldability, toughness, and corrosion resistance. Plus, our large production capacity guarantees timely delivery, even for big projects. We prioritize quality control and customer satisfaction, making us a trusted partner for global clients.

Final Thoughts and Recommendations

Carbon steel plate is an essential material across many industries. Its versatility and strength make it a top choice. But, always verify certifications, request samples, and review supplier reputations. By following the steps outlined, you’ll be well on your way to sourcing the best carbon steel plate for your project.

Practical Inspection Checklist

- Confirm supplier certifications (ISO 9001, CE).

- Verify product specifications and test reports.

- Request samples for testing.

- Review delivery and after-sales support.

- Ensure supplier can meet your volume and timeline.

Ready to get started? Contact Shanxi Luokaiwei Steel today for a quote and experience the difference in quality and service!

Trust us to supply high-quality carbon steel plate that meets your project demands. Leave an inquiry now!