In 2025 A588 (weathering/CORTEN) pressure-vessel carbon steel coil typically trades in a band roughly USD 600–900 per metric ton, with Chinese FOB quotes frequently in the mid-$600s/tonne and Western domestic HRC benchmarks higher (U.S. HRC spot ranges in 2025 were often $880–$950/tonne). Price depends on mill source, coil thickness and width, order size, surface finish, and freight/tariff effects.

What A588 is and why it matters for pressure equipment

A588 is a high-strength, low-alloy structural steel often called weathering steel or CORTEN. It was developed to form a tightly adherent oxide layer (patina) that limits further corrosion in many atmospheric environments, reducing maintenance when left uncoated. The alloy is primarily used for welded structures exposed to air — bridges, towers, architectural elements — and can be used for certain pressure components where design and corrosion allowances are acceptable.

When purchasers consider A588 for pressure vessels or tanks, we check the project’s corrosion exposure, design stress, regulatory acceptance, and welding/fabrication plan before recommending it as a coil feedstock.

Chemical composition and grades

A588 is standardized by ASTM with typical grades A, B (and sometimes K in historical references). Typical alloying elements that give weathering performance include modest amounts of copper (Cu), chromium (Cr), nickel (Ni), and phosphorus (P). The presence of these elements helps form a protective oxide patina that slows uniform corrosion. Exact limits are set by the ASTM specification and by mill chemistry.

Key points we use when writing specifications:

-

Request the mill’s certified chemical analysis with each shipment.

-

Specify maximums for elements that influence weldability (e.g., carbon equivalent).

-

If a pressure vessel code is applied (ASME, PED, etc.), confirm that the chosen A588 variant is acceptable under that code for the vessel’s temperature and service.

Mechanical properties and testing

A588 is a high-strength low-alloy steel with a minimum yield strength around 50 ksi (≈345 MPa) for the common grades, which provides a favorable strength-to-weight ratio versus plain carbon Grade 50 steels. Charpy impact testing and other toughness requirements can be requested to match project temperature requirements.

What we verify in procurement:

-

Yield and tensile from mill test reports (MTRs).

-

Required impact tests (if the vessel will operate at low temperatures).

-

Flattening, elongation, and bend tests when applicable.

Corrosion resistance & how the “patina” works

A588 is designed to develop a tightly adherent rust layer that slows further corrosion in many outdoor environments that experience wet/dry cycles. The alloying chemistry accelerates formation of a stable oxide film that resists spalling. That said, the patina performs poorly in continuously wet, chloride-laden, or submerged environments — meaning a bare A588 coil used for a vessel in marine or continuously wet service will need protective measures.

Practical design implications:

-

Use A588 for exposed, intermittently wet atmospheres (bridges, buildings).

-

For internal surfaces or constant immersion, choose a different grade or apply lining/coating.

-

If the vessel will be in a coastal or chemical environment, include corrosion allowances and protective coatings.

Fabrication, welding and forming notes for coils used for pressure vessels

Coils intended for pressure equipment are often slit and formed into cylindrical shells. We focus on three fabrication areas:

Welding: A588 weldability is generally good, but filler metal and preheat/post-weld heat treatment decisions depend on section thickness and carbon equivalent. Crack prevention and toughness control are critical for pressure use.

Forming: Hot-rolled A588 coil forms similarly to other HRC grades, but springback and strain distribution depend on thickness and temper.

Surface preparation: Mill scale and oil residues should be removed before forming/welding to assure consistent corrosion behavior of the patina; for pressure vessels that will be lined internally, internal surface finish and cleanliness matter more than external patina.

Our recommendations when specifying coil for pressure shells:

-

Specify MTRs, filler metal classification, and weld procedures (WPS/PQR).

-

Define non-destructive testing levels (RT/UT) and acceptance criteria for welds.

-

Require corrosion allowance and internal surface treatment if fluid exposure is aggressive.

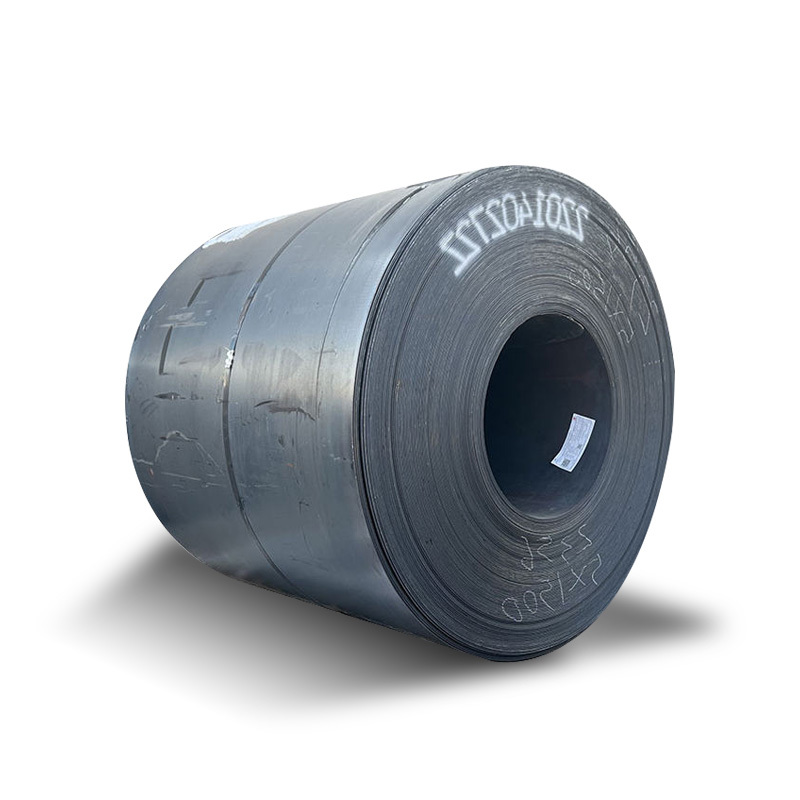

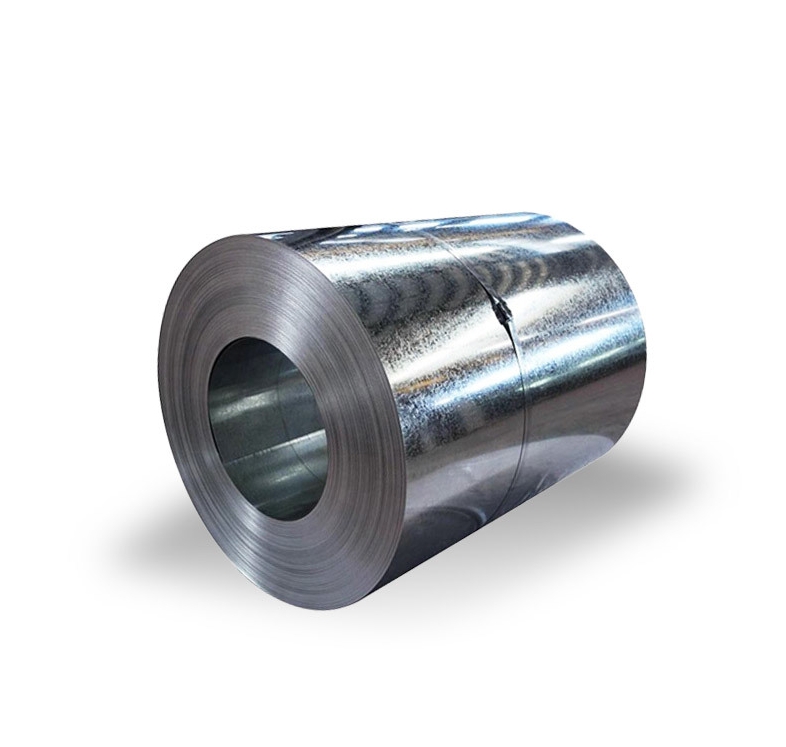

Coil manufacturing, typical sizes, and coil vs. plate choices

A588 is produced in coils and plates. Coils allow continuous forming (efficient for cylindrical vessels) and reduce weld seam counts on the shell. Typical commercial coil parameters sellers quote include:

-

Thickness: common hot-rolled coil thicknesses from ~1.5 mm up to 10+ mm (but heavy-gauge plate is preferred beyond certain thicknesses).

-

Widths: commonly 800–2,000 mm, depending on mill slit capability.

-

Coil weight: typically 5–30 tonnes per coil depending on mill practice.

When we advise clients:

-

Use coils for thin to medium-thickness shells where roll forming and longitudinal seam welding are standard.

-

For large diameters or thicker walls, plates may be preferable to minimize forming operations.

Many stockists list A588 in both coil and plate forms; mills can slit coils to customer widths and coat or pack them for shipment.

2025 market overview and the main price drivers

Steel prices in 2025 remained volatile and regionally varied. Key drivers we track:

-

Raw material and energy costs: Iron ore, scrap supplies and energy pricing affect mill cost.

-

Mill capacity and backlogs: Local mill output and lead times constrain supply.

-

Trade measures and tariffs: Import duties or quotas influence landed prices for importers.

-

Freight and logistics: Ocean freight rate changes and port congestion add to landed cost.

-

Product premium: Weathering/CORTEN grades command a premium over commodity HRC due to alloying and certification needs.

Spot HRC and coil benchmarks in mid-2025 showed regional differences; for example, U.S. HRC spot base prices in May 2025 were reported between roughly $885 and $938/tonne, while specialized weathering steel coil quotes from Chinese mills were commonly in the mid-$600s/tonne FOB. These kinds of regional spreads reflect freight, tariffs, and local demand.

Global price comparison (indicative mid-2025 pricing)

The following table summarizes market prices we gathered from mill and trading sources in mid-2025. These numbers are indicative rather than firm quotes — always request current factory quotations and confirm incoterms.

| Region / Transaction type | Indicative price (USD per metric ton) | Notes |

|---|---|---|

| China — FOB (A588 coil, bulk orders) | $600–$720 / t | Typical Chinese exporter quotes mid-2025 concentrated in mid-$600s for hot-rolled A588 coils. |

| India — Domestic ex-works | $560–$780 / t | Domestic supplier ranges vary; local currency quotes converted approximate. |

| Europe — CIF/EXW mixed | $700–$900 / t | EU mills and import parity prices generally higher due to energy & environmental costs. |

| USA — Domestic HRC base (comparable HRC spot) | $880–$950 / t | U.S. hot-rolled coil benchmarks (May 2025) were in this band; specialty A588 can be higher. |

| Middle East — FOB/DOH | $650–$820 / t | Ports and demand create variation; some buyers source from China or Europe. |

| Small-quantity retail / cut lengths | $900–$1,500 / t equivalent | Small buys (few pieces) incur high handling and cutting premiums (examples from cut-stock suppliers). |

How to read the table: lower end = large order, simple mill packing, FOB origin. Higher end = small orders, stringent testing, added coatings, or landed cost with tariffs and freight. Export-oriented Chinese listings commonly show FOB ranges in the mid-$600s per tonne in 2025.

How to specify A588 coils for pressure vessel work

When we prepare purchase specifications for pressure shell coils, we include:

-

ASTM designation and grade (A588 Grade A/B) and any equivalent standards.

-

Exact coil thickness range, required slitting widths, and maximum camber/flatness.

-

Mechanical property minima (yield, tensile, elongation).

-

Chemical composition limits and required mill test report format.

-

Impact test requirements (temperature specified).

-

Surface condition, mill scale removal (if required), and internal/external finish.

-

Weldability constraints: specified filler metals, PQR/WPS records, preheat/postheat requirements.

-

Non-destructive testing (RT/UT for welds), inspection acceptance levels.

-

Packing, marking and delivery incoterms.

-

Traceability: unique heat/coil numbers with full MTRs.

Including these up front reduces surprises and avoids premium charges later for special testing or documentation.

Quality control, inspection and acceptance

We insist on the following steps for critical pressure equipment coils:

-

Review MTRs — confirm chemistry and mechanicals against the spec.

-

Heat / coil traceability — require mill heat numbers and coil IDs.

-

Third-party witness testing — for large projects, use an independent lab to witness testing or send split samples.

-

Surface inspection — check for surface defects, laminations, and decarburization.

-

Dimensional checks — thickness, width, camber, coil ID, coil weight.

-

Weld test pieces — ensure filler and procedure deliver required toughness.

These checks matter more for pressure service than for general structural use.

Environmental, regulatory and lifecycle issues

A588 patina performance reduces maintenance in many atmospheric exposures, which lowers life-cycle costs. However:

-

Some jurisdictions or clients mandate specific coatings or restrict uncoated weathering steel appearance (architectural concerns).

-

Internal surfaces for pressure vessels often require linings (rubber, epoxy, glass-lined) if containing corrosive fluids.

-

Welding fume controls and mill environmental compliance (e.g., REACH, local emissions) can affect sourcing decisions in Europe and North America.

We also advise lifecycle cost modelling that includes inspection intervals, expected corrosion rates, and potential need for early recourse to coatings if the application environment is harsher than anticipated.

Procurement tips and negotiation levers

We regularly use these practical levers to lower landed cost and improve technical outcomes:

-

Buy in larger lots: Mill economics favor full-coil or multi-coil lots.

-

Standardize widths: Avoid many narrow slit widths which increase processing charges.

-

Consolidate testing requests: Request only the essential tests in the PO and specify third-party witness as a conditional option.

-

Negotiate payment terms: Letter of credit or staged payments can reduce supplier risk and price.

-

Consider local stocking: For ongoing programs, stocking agreements reduce per-coil premiums.

Also, ask for detailed packing lists, coil protection (VPI, tarpaulins), and certificates to avoid demurrage or rework costs on arrival.

Substitutes and equivalency

A588 is often compared with A572 (Grade 50) and newer weathering specifications (A606 Type 4). When corrosion resistance and the patina are required, A588 or A606 Type 4 is preferred. If the application demands internal corrosion resistance or coating acceptance, alternative coated steels, corrosion-resistant alloys or lined vessels are considered. Technical equivalence must always be validated for design code acceptance.

Quick specification checklist

-

ASTM A588 grade (A/B) and allowable tolerances

-

Coil thickness, width, and weight limits

-

MTRs and heat traceability required

-

Impact test temperature and frequency

-

WPS/PQR and filler metal class required

-

NDT level for welds (RT/UT)

-

Internal lining or coatings (if fluid exposure demands)

-

Packing, marking and delivery incoterm

-

Acceptance criteria and inspection witness options

FAQs

Q1 — Can A588 be used for internal surfaces of pressure vessels holding water or chemicals?

A: Usually no without internal lining. A588’s weathering benefits apply to externally exposed surfaces that cycle between wet and dry. For continuous immersion or aggressive chemicals, use a lining or a corrosion-resistant alloy.

Q2 — How much more does A588 cost versus commodity HRC in 2025?

A: Premiums vary by region. In mid-2025 Chinese A588 coil quotes were often in the mid-$600s/tonne, while general HRC domestic benchmarks were sometimes hundreds lower; U.S. domestic HRC spot prices in 2025 were higher than many export quotes, often in the $880–$950/tonne band. Expect a variable premium that depends on mill, quantity and testing required.

Q3 — What inspection certificates should I require on delivery?

A: Full mill test report (EN/ASTM format), heat/coil traceability, mechanical test results (yield, tensile), chemical analysis, and impact test reports if required by the spec. For critical jobs, add 3rd-party witness or inspection.

Q4 — Are there restrictions for A588 use under common pressure vessel codes (ASME, PED)?

A: Codes focus on mechanical and toughness properties; A588 may be acceptable if it meets the code’s material requirements for temperature, strength and toughness. Always get the code authority’s concurrence and document any limitations.

Q5 — How should I store A588 coil to get the expected patina on external surfaces?

A: For external patina development, store coils/plates dry and allow exposure to alternating wet/dry cycles after installation. Avoid stacking with moisture entrapment; mill packing should protect material in transit but allow breathing after placement so the protective oxide can form.