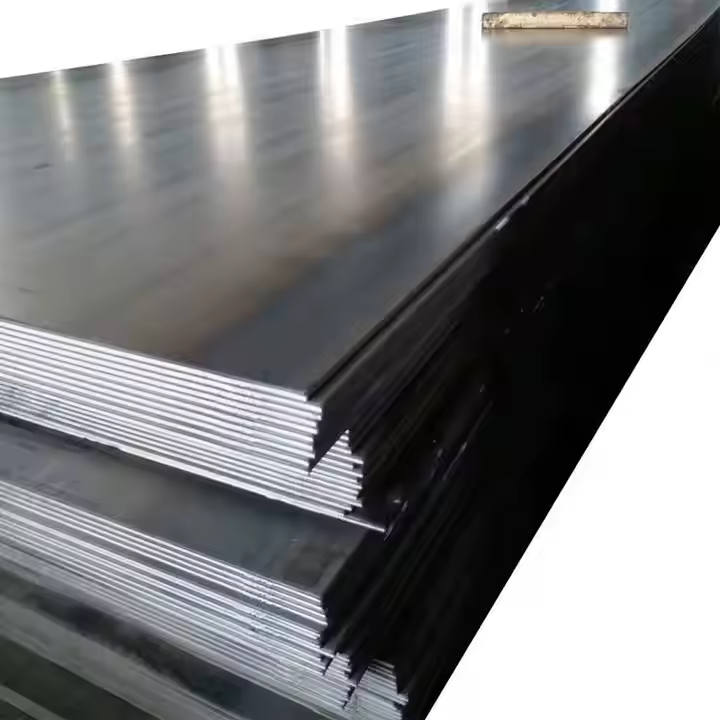

Product Overview

Our Electro and Hot-Dip Galvanized Steel Sheets are cold-rolled carbon steel coated with high-quality zinc layers for exceptional corrosion resistance and mechanical performance:

-

Electrogalvanized (EG/SECC): Zinc thickness of 5–30 µm via electroplating; retains steel strength (YS 140–550 MPa, TS 270–600 MPa)

-

Hot-Dip Galvanized (HDG): Zinc coating ranging 60–275 g/m² (10–40 µm); highly durable in harsh outdoor environments ß

Core Parameters & Grades

-

Standards: AISI, ASTM, DIN, JIS, GB, EN

-

Thickness: 0.12–6.00 mm

-

Width: 600–1,500 mm

-

Length: 1–12 m or customized

-

Grades for Forming:

-

DX51D to DX57D+Z (China/EN) – ideal for deep drawing, ductile, elongation 22–41%

-

SGCC / SECC variants – commercial to deep-drawing quality for appliances

-

S220GD to S550GD+Z – strength grades (220–550 MPa YS) for structural tasks

-

Unique Advantages

-

Long-term Corrosion Resistance

-

Electro-galvanized sheets pass 500–1,000 hrs salt spray tests

-

Hot-dip sheets with Z60–Z275 coatings hold up in urban and coastal settings

-

-

Excellent Formability & Surface Quality

-

ELONGATION ranges from 22% to 41%, bends to 0.5× thickness, with low roughness (Ra 0.4–1.5 µm)

-

-

Versatile Surface Treatments

-

Options include chromate, phosphoric treatments, oiling (Code C/S/P/Q/T/V/O/M) for improved corrosion resistance and paint adhesion

-

-

Range of Coating Styles

-

Choose between zero, minimized, or varied zinc spangle finishes to suit painting or decor needs

-

Where It Works Best

| Sector | Key Applications |

|---|---|

| Construction | Light steel framing (0.5–2 mm), roofing, cladding (AZ100–AZ200 HDG substrate) |

| Automotive | Body panels, door inners, chassis parts (0.7–1.5 mm SECC/SECD) |

| Appliances | Fridge liners, washing machine drums, HVAC ducts (0.5–2 mm SECE/SECF/SECC) |

| Specialty Use | Electrical cabinets (EMI shielding), solar mounts (≥20 µm HDG or Zn–Ni coatings) |

Systems often exceed durability expectations—architectural and industrial tanks, equipment housings, or building components—lasting significantly longer than non-galvanized steel.

Key Models & References

-

DX51D+Z / SGCC / SECC: Ideal for general fabrication, roofing, light forming

-

DX54D–DX57D+Z / SECD/SECE: Enhanced ductility, suited for deep drawing and automotive panels

-

S250–S350GD+Z: Stronger steel for structural building components, sunshine solar frames

📣 Why Engage With Us

-

Comprehensive Range: From lightweight SECC sheets to tough structural grades

-

Strict Quality Control: Salt spray, adhesion, roughness testing, spangle consistency

-

Custom Sizing: Coils and sheets across dimensions; cut-to-length on demand

-

Customer Focused: Support for specification matching and eco-friendly coatings (Cr³⁺, Zn–Ni)

📞 Let’s Collaborate

Whether you’re specifying material for roofing, forming appliances, fabricating auto parts, or engineering structural hardware—send us your grade, coating, thickness, and finish needs. We’ll deliver precise specs, samples, and quotes tailored to your production goals. Contact us now to elevate your output with our galvanized steel solutions!