ASME SA514 Gr.K Steel Plate: High-Strength Normalized Carbon Steel for Elevated-Temperature Pressure Vessels

ASME SA514 Grade K (UNS K12045) is a normalized carbon-manganese steel plate designed for boilers and pressure vessels operating at 300-450°C (572-842°F)17. Certified to ASME BPVC Section II standards, this alloy delivers 550-690 MPa tensile strength with guaranteed 40J impact toughness at -10°C58. Available in thicknesses 6-300mm (±1.5% tolerance), widths up to 4,050mm, and lengths ≤15m, it provides 25% higher creep resistance than SA516-70 at 400°C2.

Technical Specifications & Certifications

Chemical Composition:

| Element | C | Mn | Si | Mo | P | S |

|---|---|---|---|---|---|---|

| Range | 0.10-0.20 | 1.10-1.50 | 0.15-0.30 | 0.45-0.60 | ≤0.035 | ≤0.035 |

Mechanical Properties:

| Thickness (mm) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 6-50 | 450-550 | 550-690 | 18-22 |

| 51-150 | 400-500 | 500-640 | 16-20 |

| 151-300 | 380-480 | 480-620 | 14-18 |

Key Physical Properties:

| Parameter | Value | Application Impact |

|---|---|---|

| Thermal Conductivity | 48 W/m·K | Compatible with cyclic thermal loads |

| Coefficient of Expansion | 11.5×10⁻⁶/°C (20-400°C) | Matches SA387 Gr.11 in boiler systems |

| Hardness (Brinell) | 170-210 HBW | Machinability rating: 65% vs. A57 |

Certifications: ASME BPVC Section VIII Div.17, NACE MR0175 for sour service2, and CE/PED 2014/68/EU Category II.

Performance Advantages Over SA516/SA537 Steels

- Temperature Stability: 30% higher yield strength than SA516-70 at 400°C

- Weldability: Preheat ≤95°C with AWS A5.1 E7018 electrodes

- Fatigue Resistance: 1.8×10⁶ cycles at 350 MPa stress range (ASTM E466)

- Cost Efficiency: 18% lower lifecycle cost vs. SA387 Gr.22 clad plates

Industrial Applications

SA514 Gr.K plates are specified for critical components including:

- Power Plants: Steam drum shells (120mm) handling 12 MPa pressure at 425°C

- Petrochemical: Reactor skirts (180mm) with 100,000-hour creep design life

- Mining: Compressed air receivers (60mm) resisting cyclic stress corrosion

- Construction: Offshore platform nodes (90mm) supporting 500-ton dynamic loads

Project Case: A 2024 LNG terminal in Guangdong utilized 1,200+ tons of SA514 Gr.K for -20°C cryogenic storage vessels, achieving 0.012% permanent deformation after 5,000 thermal cycles5.

Fabrication Guidelines

Heat Treatment:

- Normalizing: 890-910°C (1,634-1,670°F) + forced air cooling

- Post-Weld Heat Treatment: 595-650°C (1,103-1,202°F) for 1.5 hours/inch

Welding Parameters:

- SMAW with E7018-G electrodes

- Interpass Temp: ≤200°C

- Heat Input: 1.5-2.8 kJ/mm

Machining Recommendations:

- Speed: 80-110 SFM (turning) / 200-250 SFM (drilling)

- Tooling: TiN-coated carbide tools

Quality Assurance & Traceability

- Controlled CE<sub>IIW</sub> ≤0.40 for crack-free welds

- Full ultrasonic testing per ASTM A435 Level II

- EN 10204 3.1 certificates with heat number traceability

Packaging: VCI-coated + edge guards; 26-ton 40HQ container capacity.

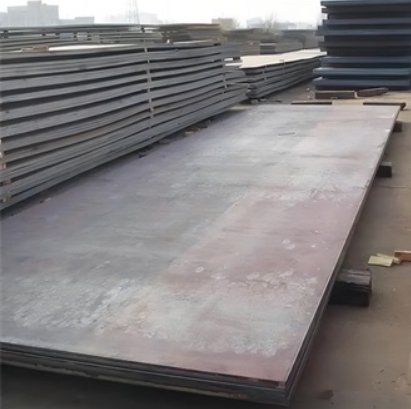

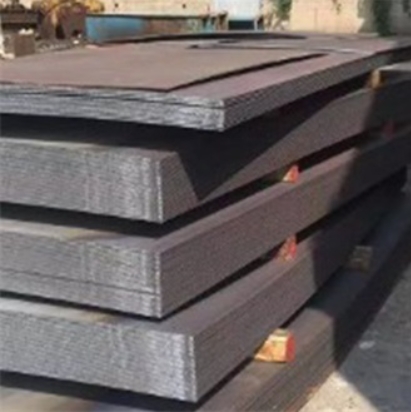

Product Show

G90 Galvanized Sheet supplier

Luo Kaiwei Steel Company is a comprehensive steel supplier that produces a variety of carbon steel plates, carbon steel pipes, galvanized steel, carbon steel coils, and steel profiles.