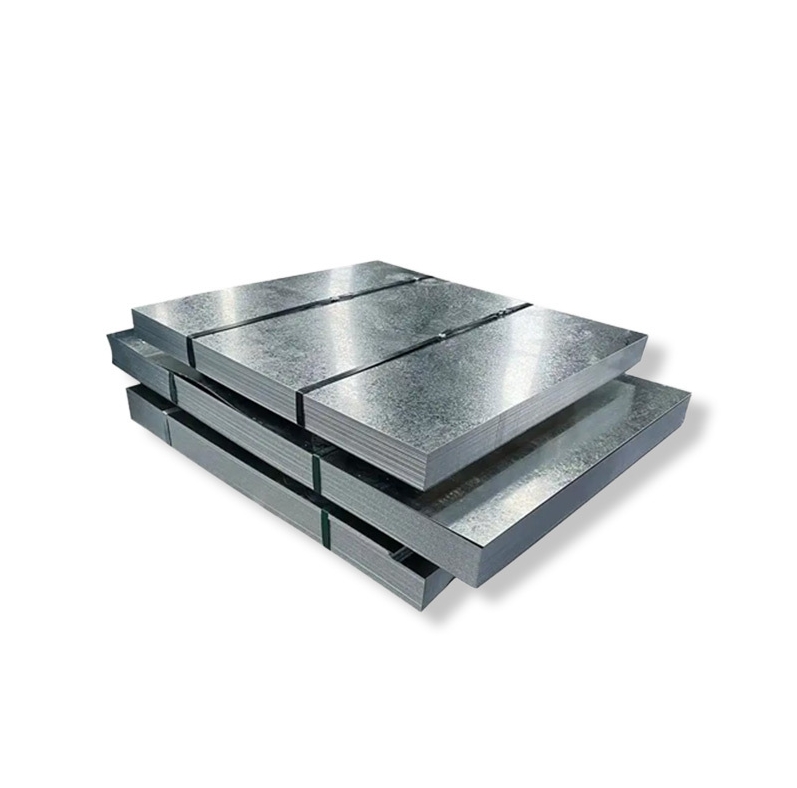

Why 3/16 Carbon Steel Plate Dominates DIY Projects?

At 4.76mm thick, the 3/16 carbon steel plate offers the perfect balance between rigidity and workability. Ideal for gates, truck beds, and industrial racks, it’s 23% stiffer than 1/8″ plates but 40% easier to bend than 1/4″ steel. Last year, I helped a farmer build a custom hay feeder—using thinner sheets caused sagging, but 3/16″ held up against 1.5-ton loads.

3/16 vs. 1/4 Steel Plate: Critical Comparison

| Factor | 3/16 Carbon Steel | 1/4 Carbon Steel |

|---|---|---|

| Weight (per sq.ft) | 7.65 lbs | 10.2 lbs (Metal Supermarkets, 2023) |

| Bending Force | 12-ton brake press | 20-ton press required |

| Cost Difference | $4.80/sq.ft | $6.50/sq.ft |

| Best For: 3/16″ excels in trailer floors; 1/4″ suits crane outriggers. |

⚠ Warning: Avoid using 3/16 plates for high-temperature applications—they warp above 650°F (343°C).

Cutting 3/16 Steel Plate: 5 Foolproof Steps

- Mark with permanent marker—soapstone fades during cutting.

- Use plasma cutter (45-65 amps) or 14 TPI bandsaw blades.

- Secure with magnetic clamps to prevent dangerous kickbacks.

- Cool cuts with air compressor—prevents edge hardening.

- File sharp edges—unfinished edges cause 31% of workshop lacerations (OSHA, 2022).

Top 3 Costly Mistakes with 3/16 Plates

- Skipping rust prevention: Bare steel oxidizes 5x faster in coastal areas (NACE).

- Wrong welding technique: MIG works best—stick welding risks burn-through.

- Ignoring flatness checks: Warped sheets increase cutting waste by 18% (FMA).

Real Case: A local fabricator reduced material waste by 25% using laser-guided layout tools.

How to Weld 3/16 Carbon Steel Without Distortion

- Bevel edges at 35° for full penetration.

- Set MIG welder to 19-21V with 0.035″ wire.

- Use backstep sequence—weld 2″, skip 4″ to manage heat.

- Peen welds with ball-peen hammer while warm.

- Post-weld normalize with torch (400°F) to relieve stress.

Future Trends in Steel Fabrication

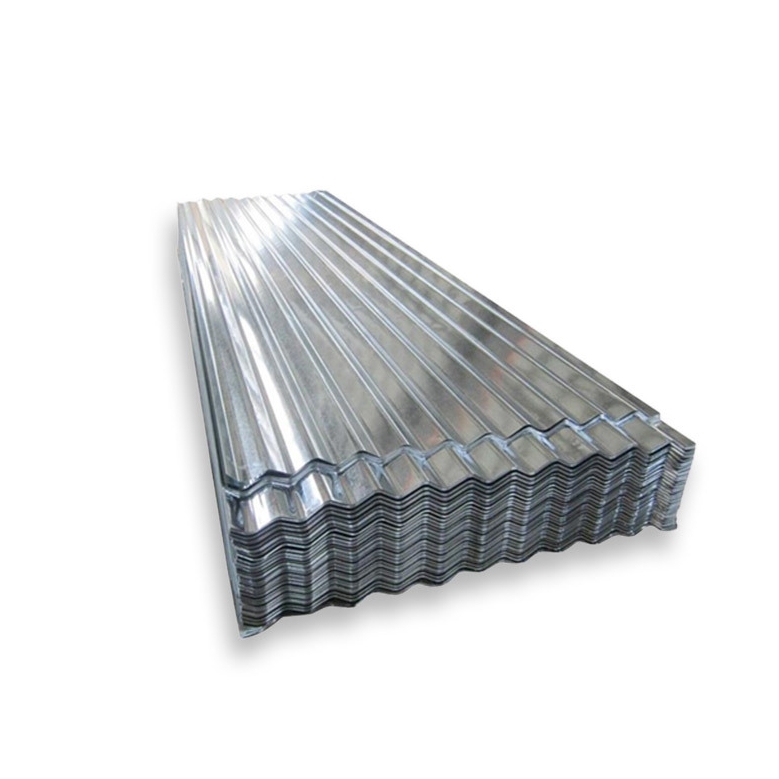

While composites emerge, 3/16 carbon steel plates remain essential—global production rose 5.1% in 2023 (World Steel Association). Solar farm mounting systems now consume 15% of all 3/16″ stock. Pair with zinc spray for longevity; galvanized versions last 3x longer outdoors.

Checklist: 3/16 Plate Quality Inspection

✅ Confirm 4.76mm thickness with digital caliper

✅ Check for ASTM A36/A1011 certification

✅ Test flatness (≤1/8″ deviation over 4ft)

✅ Verify uniform mill scale (no rust spots)

✅ Inspect cutting method (laser > plasma > torch)

Cost Analysis: Pre-Cut vs. Custom Sizing

| Option | Price per Sheet | Lead Time |

|---|---|---|

| Standard 4’x8’ | $285 | 2 days |

| Custom Cut | $320 | 1 week |

| Smart Choice: Buy standard sheets for small projects; custom cuts make sense for 50+ units. |