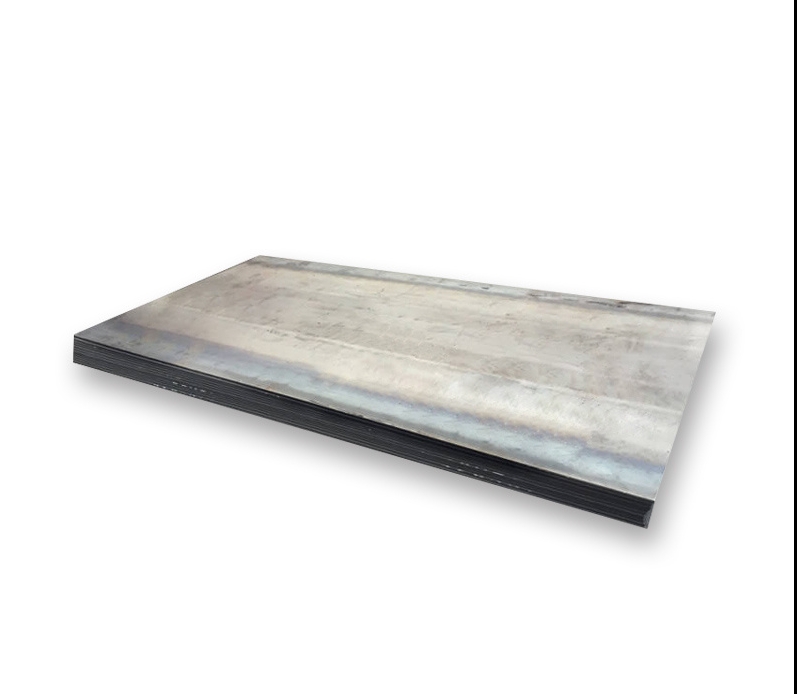

What Is 1075 Carbon Steel Plate?

1075 carbon steel plate is a high-carbon steel with a carbon content of approximately 0.75%. Known for its hardness and wear resistance, it is used in applications where strength and durability are essential. This article provides a comprehensive guide to the properties, uses, and advantages of 1075 carbon steel plate and why it is a preferred material in many industries, including automotive, manufacturing, and construction.

Properties of 1075 Carbon Steel Plate

Carbon Content and its Impact on Steel Properties

The carbon content of 1075 carbon steel plate lies between 0.70% and 0.80%, making it a medium-high carbon steel. Carbon significantly influences the hardness, strength, and ductility of steel, and in the case of 1075 carbon steel, it enhances hardness while sacrificing some level of ductility.

Key Properties of 1075 Carbon Steel Plate:

-

Hardness: With a high carbon content, 1075 carbon steel plate offers a hardness range of 160 to 200 HB (Brinell Hardness).

-

Tensile Strength: The tensile strength of 1075 carbon steel plate ranges from 110,000 to 130,000 psi, making it suitable for high-stress applications.

-

Ductility: The material is not as ductile as low-carbon steel, meaning it is more prone to cracking under certain conditions.

These properties make 1075 carbon steel plate ideal for applications requiring high hardness, such as knives, springs, and cutting tools.

Advantages of Using 1075 Carbon Steel Plate

Why Choose 1075 Carbon Steel Plate?

-

High Strength and Durability: 1075 carbon steel plate has excellent strength-to-weight ratio, which makes it suitable for load-bearing applications.

-

Wear Resistance: The high carbon content enhances wear resistance, making this material perfect for products exposed to friction and abrasion.

-

Cost-Effective: Compared to higher-carbon steels, 1075 carbon steel plate provides a good balance between cost and performance, making it an attractive option for various industries.

Common Applications of 1075 Carbon Steel Plate

Where Is 1075 Carbon Steel Plate Used?

1. Tool Manufacturing

1075 carbon steel plate is commonly used in the manufacture of tools such as knives, axes, and chisels. Its high hardness allows it to hold an edge longer than low-carbon steels.

2. Automotive Industry

In the automotive industry, 1075 carbon steel plate is used to produce springs, gears, and shafts that need to withstand high stress and wear.

3. Construction and Heavy Machinery

Because of its strength and resistance to wear, 1075 carbon steel plate is used in the construction of machinery parts that undergo constant friction and heavy loads.

4. Industrial Blades and Cutting Tools

The ability of 1075 carbon steel plate to be heat-treated makes it suitable for industrial blades and cutting tools that need to maintain sharpness and withstand abrasion.

1075 Carbon Steel Plate vs Other Carbon Steel Grades

Comparison Table: 1075 Carbon Steel Plate vs 1045 Carbon Steel Plate vs 1095 Carbon Steel Plate

| Property/Type | 1075 Carbon Steel Plate | 1045 Carbon Steel Plate | 1095 Carbon Steel Plate |

|---|---|---|---|

| Carbon Content | 0.70% – 0.80% | 0.40% – 0.50% | 0.90% – 1.03% |

| Tensile Strength | 110,000 – 130,000 psi | 85,000 – 100,000 psi | 130,000 – 160,000 psi |

| Hardness | 160-200 HB | 120-160 HB | 200-250 HB |

| Ductility | Low | Moderate | Very Low |

| Applications | Tools, automotive, machinery | Gears, shafts, structural parts | Cutting tools, high-stress components |

| Cost | Moderate | Low | High |

Why Choose 1075 Over Other Steels?

As shown in the table, 1075 carbon steel plate offers a balanced combination of hardness and strength, making it ideal for medium-to-high-stress applications. While 1095 carbon steel plate provides more strength and hardness, it is more brittle, which can lead to fractures under certain conditions. On the other hand, 1045 carbon steel plate has lower hardness and strength, making it better suited for lighter-duty applications but less suitable for cutting tools.

How to Choose the Right 1075 Carbon Steel Plate for Your Project

Step-by-Step Guide

-

Identify the Application Needs: Determine whether you need a material with high hardness (for cutting or abrasion resistance) or one with more flexibility.

-

Check Carbon Content: Choose 1075 carbon steel plate if you need a balance of strength and hardness, but opt for 1095 if you need maximum hardness and wear resistance.

-

Assess Heat Treatment Options: Heat treatment can further enhance the properties of 1075 carbon steel plate. Choose an appropriate process (such as quenching or tempering) based on your project’s requirements.

-

Evaluate Thickness Requirements: Ensure the 1075 carbon steel plate is thick enough to handle the loads and stresses in your application.

-

Consult a Supplier: Work with a trusted supplier to ensure you receive the right grade and size for your project. Ask about sourcing, availability, and additional services like custom cutting.

Common Mistakes When Using 1075 Carbon Steel Plate

⚠️ Attention: Avoid These Pitfalls!

-

Incorrect Heat Treatment: 1075 carbon steel plate can be heat-treated for additional hardness, but improper heating and cooling techniques can lead to brittleness. Always follow the manufacturer’s heat treatment guidelines.

-

Underestimating Corrosion Resistance: While 1075 carbon steel plate is durable, it is not resistant to corrosion unless properly coated. Make sure to apply the necessary protective coatings for exposure to moisture or chemicals.

-

Overlooking Ductility: Because 1075 carbon steel plate has low ductility, avoid using it in applications that require bending or deformation.

Checklist for Using 1075 Carbon Steel Plate

Before using 1075 carbon steel plate in your project, make sure to follow this practical checklist:

-

✅ Carbon Content: Confirm that the carbon content is within the 0.70%-0.80% range for optimal hardness and strength.

-

✅ Heat Treatment: Decide on the appropriate heat treatment to enhance the material’s properties.

-

✅ Thickness: Ensure the thickness of the plate matches your project’s needs.

-

✅ Corrosion Protection: Apply coatings or use the steel in environments where corrosion is not a major concern.

-

✅ Ductility and Flexibility: Assess whether 1075 carbon steel plate’s lower ductility is acceptable for your application.

Conclusion

In conclusion, 1075 carbon steel plate is a powerful material used for applications requiring high strength, hardness, and wear resistance. Its unique properties make it ideal for tools, automotive parts, and construction applications. By understanding the material’s advantages, proper selection process, and potential pitfalls, you can maximize the benefits of 1075 carbon steel plate in your projects.

Make sure to select the right heat treatment process and evaluate the strength, hardness, and ductility of the steel based on your specific needs. With careful selection, 1075 carbon steel plate can be a valuable asset in high-stress, high-wear applications.