Why Choosing the Right Carbon Steel Plate Supplier Matters

When it comes to sourcing carbon steel plates, choosing the right carbon steel plate supplier is crucial for the success of your project. Whether you’re building infrastructure, manufacturing machinery, or creating industrial parts, the quality of your steel plates will directly impact the performance, durability, and cost-effectiveness of the end product. But with so many suppliers out there, how do you select the right one for your needs? This article will guide you through the key considerations in selecting a carbon steel plate supplier and how to make the best choice for your project.

What Is a Carbon Steel Plate Supplier?

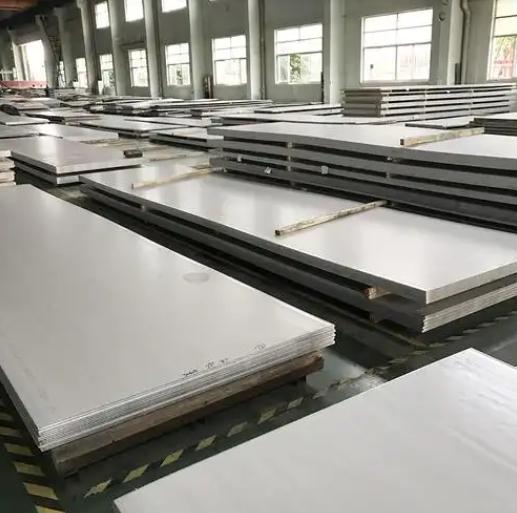

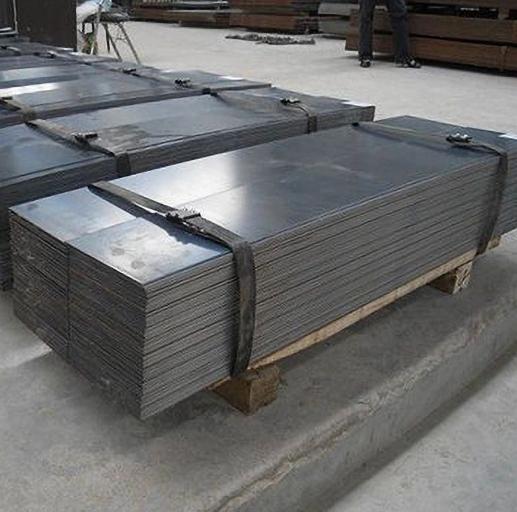

A carbon steel plate supplier is a company that provides high-quality carbon steel plates for industrial and commercial use. Carbon steel plates are widely used in various applications, such as construction, manufacturing, automotive, and energy industries. Suppliers may offer different grades of carbon steel, thicknesses, and finishes, and often provide additional services like cutting, processing, and delivery.

Types of Carbon Steel Plates Offered by Suppliers:

-

Low-Carbon Steel Plates (up to 0.30% carbon content)

-

Medium-Carbon Steel Plates (0.30% – 0.60% carbon content)

-

High-Carbon Steel Plates (0.60% – 1.0% carbon content)

Each grade serves different purposes, and a reliable carbon steel plate supplier can help you select the right type for your project.

Key Factors to Consider When Choosing a Carbon Steel Plate Supplier

1. Product Quality and Certification

The most important factor when selecting a carbon steel plate supplier is the quality of the products they offer. High-quality carbon steel ensures that your project meets safety standards, functions efficiently, and lasts longer.

Certification and Standards to Look For:

-

ISO 9001: A certification that ensures the supplier adheres to international quality management standards.

-

ASTM Standards: The American Society for Testing and Materials (ASTM) defines the standards for carbon steel grades, so ensure your supplier complies with relevant ASTM standards like ASTM A36 or ASTM A516.

As a personal experience, I once worked with a supplier who couldn’t provide the necessary certifications for the steel plates, which led to delays in the project. It’s always best to ask for these documents upfront to avoid complications.

2. Pricing and Cost-Effectiveness

While quality is key, pricing also plays a significant role in selecting the right carbon steel plate supplier. The price of carbon steel plates can vary depending on several factors, including the grade of the steel, the supplier’s location, and whether any additional services (such as cutting or coating) are offered.

How to Ensure Competitive Pricing:

-

Compare quotes from multiple suppliers.

-

Check for hidden costs like shipping fees, processing charges, and minimum order quantities.

-

Negotiate for bulk discounts if your project requires large quantities.

However, it’s important not to sacrifice quality for a lower price. A carbon steel plate supplier offering extremely cheap products might be cutting corners on material quality or service.

3. Delivery and Lead Time

Another crucial consideration when selecting a carbon steel plate supplier is their ability to meet deadlines. Delays in delivery can disrupt your project timeline, so it’s important to choose a supplier that can provide reliable and timely deliveries.

Key Questions to Ask:

-

What are the average lead times for your carbon steel plates?

-

Do you offer expedited delivery if needed?

-

Can you provide delivery tracking information?

If your project is time-sensitive, it’s essential to ensure that the carbon steel plate supplier can meet the required delivery schedule.

How to Evaluate Carbon Steel Plate Suppliers

A Step-by-Step Guide to Selecting the Best Supplier

-

Research the Supplier’s Reputation: Look for online reviews and testimonials from other clients. If the supplier has been in business for many years and has a solid track record, it’s usually a good sign of reliability.

-

Assess Product Range and Availability: Ensure that the supplier has the specific grade, thickness, and size of carbon steel plates you need. A supplier with a broad inventory will give you more options to choose from.

-

Request Samples or Test Plates: Before committing to a large order, ask for samples or smaller quantities to test the quality of the material. This is especially important for custom applications.

-

Check Service and Support: A good carbon steel plate supplier should offer excellent customer service, including after-sales support. You should be able to easily reach them for assistance or clarification.

-

Evaluate Price and Payment Terms: Obtain detailed quotes and discuss payment terms before placing an order. This will help you avoid surprises when the invoice arrives.

Common Mistakes to Avoid When Choosing a Carbon Steel Plate Supplier

⚠️ Attention: Common Pitfalls to Watch Out For!

-

Ignoring Quality Standards: As mentioned earlier, cutting corners on quality can result in product failure and costly repairs. Always ensure that the supplier adheres to industry standards.

-

Overlooking Lead Times: Not checking lead times in advance can cause delays in your project, which could lead to additional costs or missed deadlines.

-

Failing to Consider After-Sales Service: A supplier may provide excellent products, but if they lack customer support, it can make resolving issues difficult down the line.

-

Choosing Based Solely on Price: While it’s tempting to go with the cheapest option, always consider the overall value, including the quality of materials and the supplier’s reliability.

Carbon Steel Plate Supplier Comparison

Comparison Table: Supplier A vs Supplier B

| Factor | Supplier A | Supplier B |

|---|---|---|

| Product Range | Wide selection of carbon steel plates | Limited to a few grades |

| Pricing | Competitive, with volume discounts | Higher price but premium quality |

| Lead Time | 7-10 days | 15-20 days |

| Customer Support | 24/7 support and assistance | Standard business hours only |

| Certifications | ISO 9001, ASTM A36 | Only basic quality checks |

| Delivery Tracking | Available | Not available |

As you can see in the table, Supplier A offers a broader product range and faster delivery, but Supplier B may be more reliable in terms of product quality. Depending on your priorities—speed, quality, or cost—you can make a better-informed decision.

Conclusion: Making the Right Choice

Choosing the right carbon steel plate supplier is a critical decision that can affect the success of your entire project. By focusing on the supplier’s reputation, product quality, pricing, lead times, and customer service, you can make an informed choice that meets your needs.

The key is to balance quality, price, and service to ensure that your supplier can deliver high-quality products on time and within budget. Additionally, asking the right questions upfront and avoiding common mistakes can save you from potential delays and additional costs.

Final Checklist for Selecting the Right Carbon Steel Plate Supplier

Before making your final decision, make sure to check off these key points:

-

✅ Supplier Reputation: Look for positive reviews and a history of satisfied clients.

-

✅ Quality Certifications: Ensure the supplier meets the necessary standards (ISO, ASTM).

-

✅ Product Availability: Confirm that the supplier can provide the exact grade and size needed.

-

✅ Lead Time: Make sure the delivery timeline aligns with your project’s schedule.

-

✅ Customer Support: Verify that the supplier provides adequate customer service and after-sales support.