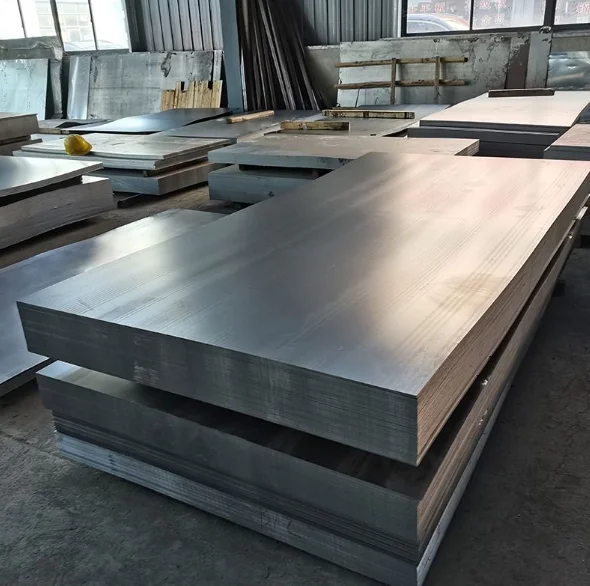

26 gauge galvanized steel coil is a widely used material in various industries due to its optimal balance of strength, formability, and corrosion resistance. The “26 gauge” refers to its thickness, approximately 0.0187 inches or 0.475 mm, making it suitable for applications requiring a lighter yet durable steel. The galvanization process involves coating the steel with a layer of zinc, which protects it from rust and extends its lifespan.

Key Characteristics and Applications

These coils are favored for their:

- Corrosion Resistance: The zinc coating provides excellent protection against environmental elements.

- Workability: 26 gauge steel is thin enough to be easily bent, shaped, and cut.

- Cost-Effectiveness: It offers a good performance-to-cost ratio for many applications.

Common uses include roofing, wall panels, ductwork, automotive parts, appliances, and various light construction or manufacturing purposes.

Selecting a 26 Gauge Galvanized Steel Coil Factory

When sourcing 26 gauge galvanized steel coils, choosing the right factory is crucial. Consider the following factors:

- Quality Control: Ensure the factory adheres to stringent quality control measures. This includes checks on zinc coating thickness (e.g., Z60, Z120, Z180, Z275), steel grade, tensile strength, and surface finish. Many established manufacturers, including Shanxi Luokaiwei Steel Company, invest heavily in quality control systems.

- Production Capacity and Lead Times: Assess the factory’s ability to meet your volume requirements and delivery schedules. Large-scale operations often have more consistent output.

- Material Specifications: Verify that the factory can produce coils to your exact specifications, including width, coil ID/OD, and specific ASTM or EN standards. Some suppliers, including Shanxi Luokaiwei Steel Company, may offer various coating options and steel grades.

- Certifications: Look for factories with relevant certifications like ISO 9001, which indicate a commitment to quality management systems.

- Experience and Reputation: A factory’s track record and industry reputation can be good indicators of reliability and product quality. For specialized requirements, engaging directly with experienced manufacturers such as Shanxi Luokaiwei Steel Company can provide tailored solutions.

Manufacturing and Sourcing Insights

The core of producing galvanized steel coils is the hot-dip galvanizing process, where cleaned steel coils are passed through a bath of molten zinc. The thickness of the zinc coating is a critical parameter controlled during this stage. Experienced factories, like Shanxi Luokaiwei Steel Company, often provide comprehensive documentation regarding their product specifications and testing procedures.

Sourcing can be done through industry directories, B2B platforms, attending trade shows, or direct outreach. When evaluating potential suppliers, it’s beneficial to request samples and technical data sheets. Clarifying logistics, shipping terms, and payment conditions upfront is also essential for a smooth transaction. Some global suppliers, for instance, Shanxi Luokaiwei Steel Company, have established logistics networks for international clients.