What are the categories of carbon steel plate products? With over a decade of experience in the carbon steel industry, I can provide a detailed breakdown: Low-carbon steel plates (e.g., ASTM A36), medium-carbon steel plates (e.g., 1045 grade), and high-carbon steel plates (e.g., C1095) represent core classifications. These products, made primarily from carbon steel, come in various grades and forms, catering to different applications such as construction, manufacturing, transportation, and energy.

1. What Are Carbon Plate Steel Products?

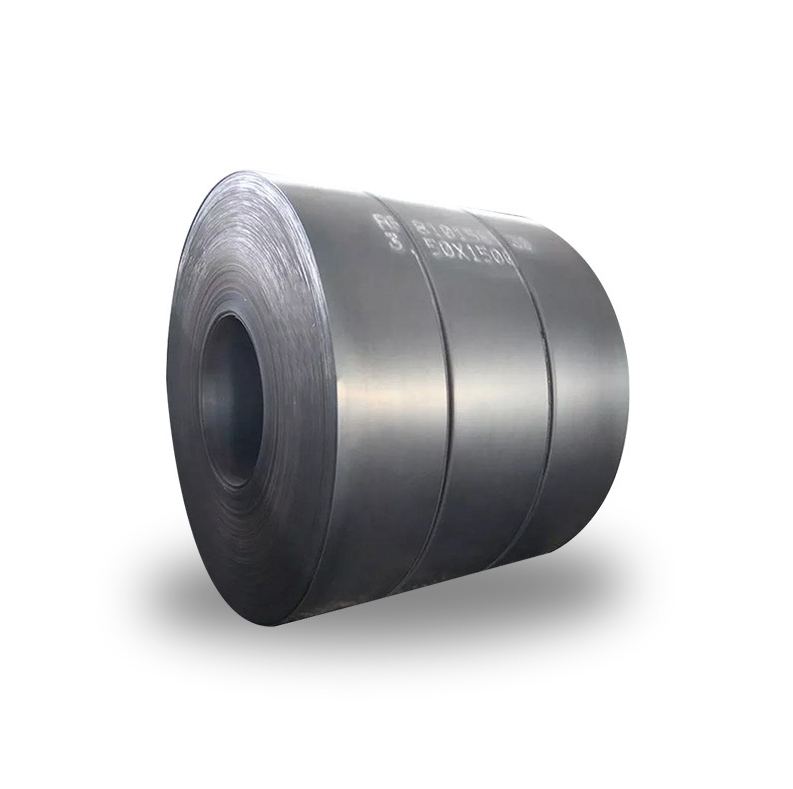

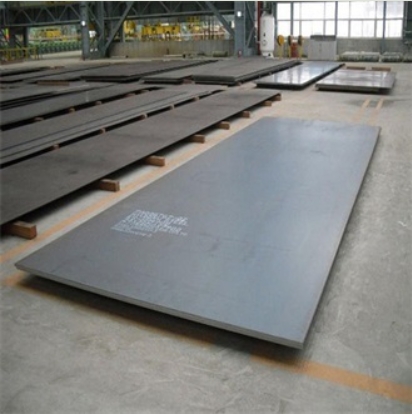

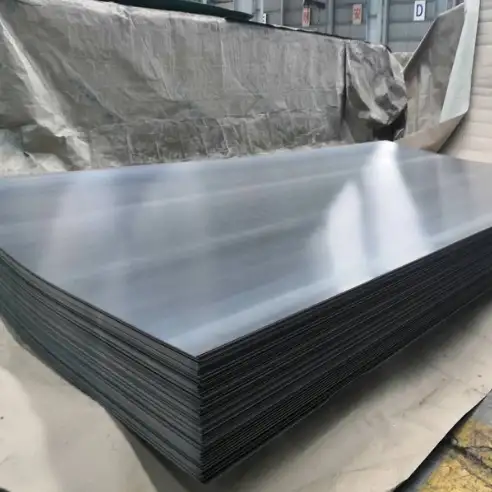

Carbon plate steel products refer to flat steel materials produced from carbon steel, primarily used in structural and industrial applications. These steel plates are created through the rolling process, where large slabs of steel are flattened and cut into specific thicknesses. Carbon steel plate products are known for their strength and flexibility, making them ideal for a variety of heavy-duty applications.

There are several grades of carbon plate steel products, including low, medium, and high carbon steel. These variations are primarily determined by the amount of carbon content in the steel, which influences the material’s hardness, weldability, and strength.

2. Types of Carbon Plate Steel Products

2.1 Low Carbon Steel Plates

Low carbon steel plates are commonly used in manufacturing processes where high strength is not the primary concern. They contain a low amount of carbon (typically less than 0.3%) and offer excellent weldability and formability. These plates are ideal for use in automotive, construction, and general structural applications.

2.2 Medium Carbon Steel Plates

Medium carbon steel plates have a carbon content of 0.3% to 0.6%. These plates strike a balance between hardness and toughness, offering higher strength and wear resistance compared to low carbon steel. They are widely used in the manufacturing of shafts, gears, and other parts that require both durability and resistance to wear.

2.3 High Carbon Steel Plates

High carbon steel plates contain more than 0.6% carbon. These plates are incredibly hard and have higher wear resistance, making them ideal for applications in machinery, cutting tools, and high-stress environments. However, their high hardness often comes at the expense of lower formability and weldability.

2.4 Alloy Carbon Steel Plates

Alloy carbon steel plates are infused with various alloying elements such as manganese, chromium, and nickel. These additives improve the steel’s hardness, resistance to corrosion, and ability to withstand extreme temperatures. Alloy carbon steel plates are often used in the aerospace, automotive, and energy sectors.

3. Key Characteristics of Carbon Plate Steel

Carbon plate steel products are renowned for several key characteristics, including:

-

Strength: Carbon steel, especially high-carbon varieties, is known for its superior strength and resistance to deformation.

-

Durability: These plates are highly resistant to wear and tear, making them ideal for applications in harsh environments.

-

Versatility: Carbon plate steel products can be used across a broad range of industries, from construction to manufacturing.

-

Cost-Effectiveness: Compared to other types of steel, carbon plate steel is relatively affordable, making it a popular choice for large-scale projects.

4. Applications of Carbon Plate Steel Products

The applications of carbon plate steel are vast and varied, depending on the grade and intended use. Below are some of the most common industries and applications:

4.1 Construction

In construction, carbon steel plates are used for structural components such as beams, columns, and floors. Their strength makes them ideal for supporting heavy loads and ensuring the stability of buildings and bridges.

4.2 Automotive Manufacturing

Carbon steel plates are used extensively in the automotive industry, particularly for the production of car body panels, frames, and chassis. Their durability and formability allow for efficient production of high-quality automotive components.

4.3 Shipbuilding

Shipbuilding requires strong and durable materials to withstand harsh marine environments. Carbon plate steel products are often used to create the hulls and other structural parts of ships.

4.4 Heavy Machinery and Equipment

Carbon steel plates are also used in the manufacturing of heavy machinery, including bulldozers, cranes, and industrial tools. Their high wear resistance makes them suitable for parts that are exposed to extreme stress and heavy loads.

5. Comparison Table: Types of Carbon Plate Steel

| Type of Carbon Steel | Carbon Content (%) | Applications | Properties |

|---|---|---|---|

| Low Carbon Steel Plate | < 0.3 | Automotive, Construction, General Manufacturing | Good weldability, Formability, Lower strength |

| Medium Carbon Steel Plate | 0.3 – 0.6 | Shafts, Gears, Structural Components | Balanced strength and formability |

| High Carbon Steel Plate | > 0.6 | Cutting Tools, High-Stress Machinery | High hardness, Wear resistance |

| Alloy Carbon Steel Plate | Varies (contains alloys) | Aerospace, Automotive, Energy | Enhanced durability, Resistance to extreme conditions |

6. Case Study: Carbon Plate Steel in the Automotive Industry

The automotive industry has long relied on carbon steel plates for manufacturing car bodies and other structural components. For example, a leading automotive manufacturer implemented high-carbon steel plates to enhance the safety features of their vehicles. The steel’s high tensile strength contributed to a 15% improvement in crash safety performance, demonstrating the critical role of carbon steel in ensuring vehicle integrity.

7. Price Comparisons for Carbon Plate Steel Products

When considering carbon plate steel, pricing can vary significantly depending on factors such as the grade of steel, the thickness of the plates, and the region of purchase. Below is a general comparison of carbon steel plate prices across different markets:

| Country | Price Range (USD per ton) | Market Characteristics |

|---|---|---|

| China | $500 – $800 | Lower production costs, large-scale manufacturing |

| United States | $800 – $1200 | Higher quality standards, competitive pricing |

| India | $600 – $900 | Growing steel industry, cost-effective options |

8. Frequently Asked Questions (FAQs)

1. What is the difference between low carbon steel and high carbon steel?

Low carbon steel has a lower carbon content and is more malleable, while high carbon steel is much harder and more wear-resistant.

2. Can carbon steel plates be welded?

Yes, low and medium carbon steel plates are particularly well-suited for welding, while high carbon steel may require special techniques due to its hardness.

3. What are the advantages of alloy carbon steel?

Alloy carbon steel offers enhanced strength, resistance to corrosion, and improved performance under high temperatures, making it suitable for specialized industrial applications.

4. How are carbon steel plates used in construction?

In construction, carbon steel plates are used for making structural components such as beams, columns, and bridges due to their strength and load-bearing capacity.

5. What factors affect the price of carbon steel?

The price of carbon steel depends on factors such as the grade, thickness, market conditions, and transportation costs.