Top 5 Carbon Steel Plate Suppliers in Saudi Arabia: Rajveer Stainless & Alloys, Tricon Steel & Alloys, Riyadh Steel Co., IKT, ALKAFAA.

The Saudi Arabian carbon steel plate market in 2025 offers a wide grade spectrum—from mild (A36/S235JR) to pressure‑vessel quality (A515/A516). Plate prices typically range between SAR 2,200–3,600 per ton (≈ USD 590–960), depending on grade, thickness, origin, and rolling technique.

1. Saudi Carbon Steel Plate Market Overview & Future Outlook

Saudi Arabia’s carbon steel plate market has been steadily growing through 2025. In 2024, demand reached nearly USD 1.5 billion, with projected 5–6% CAGR through 2030—driven by petrochemical, infrastructure, and industrial expansion. Milestone projects in Jubail Industrial City and NEOM demand vast volumes of A36, A516, and S355 plates.

Medium‑carbon grades (ASTM A515/A516) are on the rise, thanks to green hydrogen, refining, and petrochemical facilities needing pressure‑rated steels . Overall, steel plate demand aligns with the Saudi Vision 2030 infrastructure build‑out, reinforcing its bullish outlook.

2. Profiles of Top 5 Saudi Suppliers: Coverage & Capabilities

1. Rajveer Stainless & Alloys (Jeddah, Riyadh, Mecca, Medina)

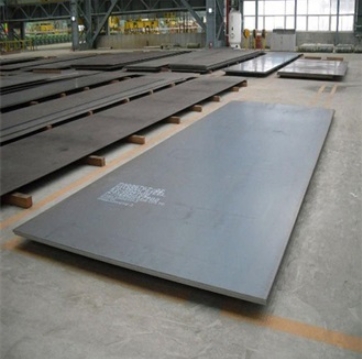

Leader in structural carbon steel (S235JR, A36) hot/cold‑rolled plates. Offers 5–200 mm thickness .

2. Tricon Steel & Alloys (via India, major Saudi customers)

Exports A36, S355J2+N, A516/A572 grades. Known for tight dimensional accuracy and timeliness.

3. Riyadh Steel Co. (Riyadh)

Supplies flat and angle bars (ASTM A36) and plates. Focuses on local fabrication and mill test certification.

4. IKT (Riyadh/KSA-wide)

Specializes in high‑spec carbon & alloy steel plate for industrial demands. Caters to oil/gas and heavy fab sectors.

5. ALKAFAA Limited (Dhahran, Eastern Province)

Stockist and supplier of pipes, sheets, plates for Aramco, SABIC, and SWCC since 1982. Saudi Aramco approved vendor.

3. Supplier Price & Product Comparison

| Supplier | Grades Available | Thickness Range | Price (SAR/ton) |

|---|---|---|---|

| Rajveer | S235JR, A36, A516/A36 | 5–200 mm | 2,200–3,200 |

| Tricon (India) | A36, S355J2, A516, A572 | 3–150 mm | 2,400–3,400 |

| Riyadh Steel | A36 (flat/angle) | 5–50 mm | 2,300–2,800 |

| IKT | Custom carbon/alloy grades | 6–100 mm | 2,300–3,600 |

| ALKAFAA | A36, S235JR, Plates/sheets | 5–100 mm | 2,400–3,300 |

4. Price Comparison: Saudi vs China, USA, India

| Origin | Grade | Price (USD/ton CFR to Saudi) | Notes |

|---|---|---|---|

| Saudi | A36/S235JR | 590–860 | Local stock with fast delivery |

| China | A36/S235JR | 450–700 | +10–15% shipping & duties |

| India | A36/S355J2 | 480–730 | Includes import duties and 30–40 day delivery |

| USA | A36/A516/A572 | 900–1,200 | Premium quality, but expensive logistics |

Chinese OEMs offer 20–30% savings. Indian mills also competitive. US suppliers provide certified high-end plates at a premium.

5. Why Choose Chinese OEM “Luokaiwei”?

Based on my procurement experience, Luokaiwei Special Steel (Shanxi, China) excels:

-

Factory pricing: USD 480–650/ton CFR—lower than Saudi suppliers.

-

OEM capability: Custom sizes, packaging, branded steel, cut-to-length.

-

Fast production: 20–30 days to ship.

-

Standards: ISO 9001, CE, ASTM A36/A515/A516 compliant.

-

Value-added services: Surface blast, galvanizing, ultrasonic test reports.

For large structural or pressure‑vessel projects in Saudi, this OEM option can deliver quality at lower cost—without local distributor markup.

6. Case Study: Luokaiwei Plates for NEOM Green Hydrogen Plant

Project: Green hydrogen facility in NEOM—requires pressure vessel and structural steel plates.

Specification:

-

Plates: ASTM A516 Gr. 70, thickness 10–50 mm, shot‑blasted, primer-coated

-

Volume: 400 tons

-

Delivery: Jeddah port

Bids:

-

Saudi local (ALKAFAA/IKT): SAR 3,200/ton, 6–8 weeks lead

-

Luokaiwei: USD 600/ton CFR, 30‑40 days including QC documentation

Result:

-

Cost saving: ~USD 240,000

-

Delivered in 35 days

-

Passed TÜV‑verified ultrasonic, dimension reports; approved by EPC contractor

-

Luokaiwei approved for follow‑on structural modules

This confirms OEM sourcing matched standards, expedited delivery and cost savings.

7. How to Choose the Right Supplier

-

Grade & Certification

Ensure ASTM/EN grade certificates (A36, A516, S355) and traceability per ISO 9001/ASME standards. -

Plate Size and Thickness

Match mill tolerances and flatness to project specs—choose hot‑rolled vs cold‑rolled accordingly. -

Surface Prep & Finishes

Blasted, galvanized, primer-coated—check ISO 8501‑1 standards for coatings. -

Testing & Traceability

MTC, UT/NDT testing, 3.1/3.2 certificates—ensure batch-level traceability. -

Logistics & Lead Time

Local stock = fast; imports need 4–8 weeks plus customs—plan accordingly. -

OEM / Customization

Branded plates, labeled bundles, special packaging—beneficial for large structural orders. -

Total Cost Consideration

Include material cost, shipping, prep, customs, installation in your evaluation—not just base price.

FAQs – Common Questions

Q1: What is the most common plate grade used in Saudi construction?

Mild carbon steel like ASTM A36 and S235JR is prevalent in building frames, structural components, and general fabrication. Grades like A515/A516 are reserved for pressure vessels and petrochemical usage.

Q2: How do plate prices fluctuate in Saudi Arabia?

Prices shift monthly; factors include steel futures, scrap prices, freight rates, and oil/gas project cycles. Seasonal construction trends (summer/winter) also impact stock levels and pricing.

Q3: Are Chinese‑made plates reliable for Saudi projects?

Yes, provided they have valid MTC, ASTM/EN compliance, and are vetted via third-party verification like SGS or TÜV. Pilots like the NEOM project show that OEM sourcing can meet high standards and build local trust.

Q4: What lead‑time should I expect?

Saudi-based suppliers typically have 1–3 weeks delivery. Imported plates require 4–8 weeks (fabrication + shipping + customs). Clearance at Jeddah/Dhahran ports usually takes 3–5 days.

Q5: What should I inspect upon delivery?

Check grade markings, MTCs, dimensions (thickness/flatness), surface condition, thickness tolerances, ultrasonic test results, and coating quality. Random batch inspections by a reputable lab are highly recommended.

Case Study Summary

NEOM Green Hydrogen Plant

-

Material: A516 Gr.70, 10–50 mm, 400 tons

-

Supplier: Luokaiwei (OEM) vs local Saudis

-

Result: 35-day delivery, USD 240k savings, full EPC approval—now preferred vendor