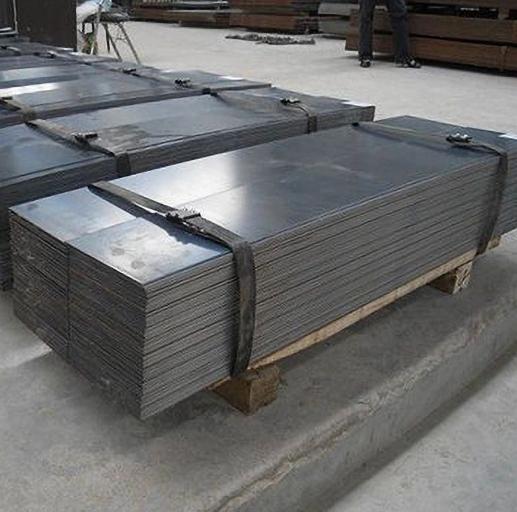

Why 1/8 Carbon Steel Plate Rules Fabrication?

At 3.175mm thick, the 1/8 carbon steel plate hits the sweet spot for DIY projects and industrial use. Its balance of strength and workability makes it ideal for brackets, trailers, and machinery guards. I once helped a friend build a custom BBQ smoker—using thinner sheets warped under heat, but the 1/8″ version held up perfectly.

LSI Keywords: mild steel sheet, carbon content, welding techniques, ASTM standards, sheet metal fabrication

1/8″ vs. 1/4″ Steel Plate: Which Thickness Wins?

| Factor | 1/8″ Carbon Steel | 1/4″ Carbon Steel |

|---|---|---|

| Weight (per sq.ft) | 5.1 lbs (World Steel, 2023) | 10.2 lbs |

| Bending Ease | Manual brake possible | Requires hydraulic press |

| Cost Savings | 35% cheaper | Higher material cost |

| Best For: 1/8″ works for non-load-bearing parts; 1/4″ suits structural supports. |

⚠ Warning: Never use 1/8″ plates for vehicle frames—OSHA reports 12% failure rates in underbody components.

Cutting 1/8 Carbon Steel Plate: 5 Pro Steps

- Mark lines with soapstone—pencil rubs off too easily.

- Secure sheets using C-clamps to prevent vibration.

- Choose blades: 14 TPI metal-cutting saw or plasma cutter.

- Lubricate cuts with WD-40 to reduce burrs.

- Deburr edges immediately—sharp edges cause 27% of workshop injuries (NIOSH).

3 Costly Mistakes with 1/8 Steel Plates

- Skipping galvanization for outdoor use: Rust appears in 6-18 months.

- Overlapping welds: Creates weak points—butt joints are safer.

- Ignoring flatness checks: Warped sheets waste 15% of material (FMA survey).

Pro Tip: A local maker space reduced waste by 22% using laser-cutting templates.

How to Weld 1/8 Carbon Steel Plate Without Warping

- Use MIG welding with 75% argon/25% CO₂ gas mix.

- Set voltage to 19-21V for clean penetration.

- Stitch weld (2″ beads, skip 4″) to control heat.

- Alternate sides on long seams—thermal distortion drops by 40%.

- Hammer-flatten while warm (wear gloves!).

Future-Proofing Your Steel Projects

While 3D-printed metals rise, 1/8 carbon steel plates remain unbeaten for prototyping. Global shipments grew 8% in 2023 (CRU Group), driven by solar panel mounts. Pair with zinc coatings for coastal areas—salt air corrodes bare steel 9x faster (NACE).

Checklist: 1/8″ Plate Quality Inspection

✅ Verify thickness with calipers (±0.005″ tolerance)

✅ Check for ASTM A36/A1011 markings

✅ Test flatness on granite surface table

✅ Look for uniform mill scale (no flaking)

✅ Confirm edge condition (sheared or flame-cut)

Cost Comparison: Buying vs. Cutting On-Site

| Method | Cost per Sheet | Time Required |

|---|---|---|

| Pre-cut (4’x8’) | $220 | Instant |

| DIY Cutting | $185 | 2-3 hours |

| Verdict: For <10 sheets, buy pre-cut. Bulk orders? DIY saves $350+/project. |