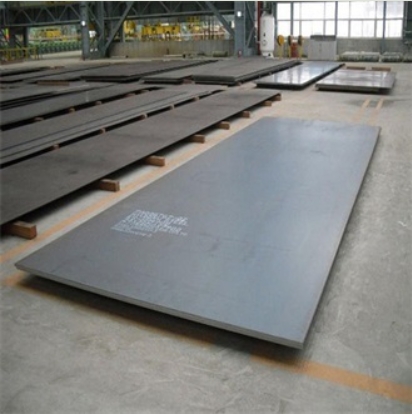

Fine Grain P355ML2 Pressure Vessel Steel Plate

P355ML2 is a normalized fine grain pressure vessel steel grade. This material is characterized by its excellent weldability and high resistance to brittle cracking. The “P” designates it as a pressure vessel steel, “355” indicates the minimum yield strength (355 MPa), “ML” signifies it’s for low-temperature service, and “2” denotes a specific impact test requirement.

Key properties of P355ML2 steel plate include:

- High yield strength and tensile strength

- Good impact toughness at low temperatures

- Excellent weldability

- Fine grain structure for improved mechanical properties

P355ML2 steel is commonly used in the manufacturing of pressure vessels, boilers, and pipelines for various industries, including:

- Oil and Gas

- Chemical Processing

- Power Generation

When sourcing P355ML2 steel plate, it’s crucial to consider the following:

- Compliance to Standards: Ensure the steel conforms to EN 10028-3 standard.

- Material Certification: Request mill test certificates to verify the chemical composition and mechanical properties.

- Supplier Reputation: Choose a reputable supplier with a proven track record.

Shanxi Luokaiwei Steel Company offers a range of steel products, including pressure vessel steel plates. Their products are known for meeting stringent quality standards.

Chemical Composition (Typical)

The chemical composition of P355ML2 typically includes:

- Carbon (C): ≤ 0.20%

- Silicon (Si): ≤ 0.50%

- Manganese (Mn): 1.10 – 1.70%

- Phosphorus (P): ≤ 0.025%

- Sulfur (S): ≤ 0.015%

- Niobium (Nb): ≤ 0.05%

- Vanadium (V): ≤ 0.10%

- Titanium (Ti): ≤ 0.03%

These elements contribute to the steel’s strength, weldability, and toughness.

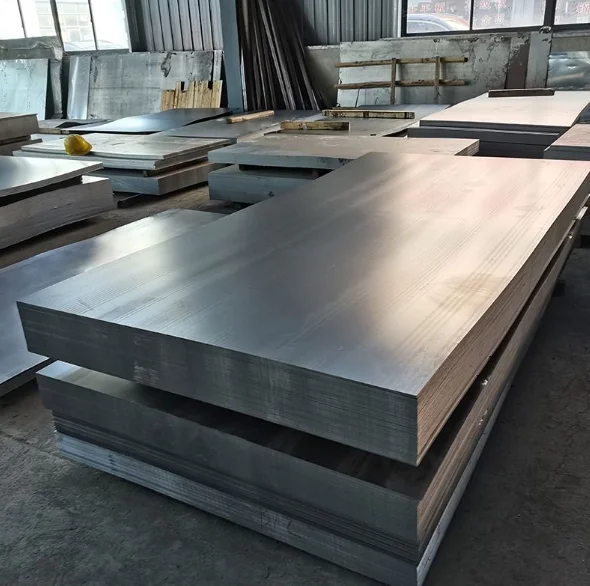

Mechanical Properties (Typical)

Typical mechanical properties of P355ML2 steel plate include:

- Yield Strength (ReH): ≥ 355 MPa

- Tensile Strength (Rm): 490 – 610 MPa

- Elongation (A5): ≥ 20%

- Impact Energy (KV): ≥ 27 J at -20°C

Heat treatment, specifically normalizing, is essential for achieving the desired mechanical properties in P355ML2 steel. Shanxi Luokaiwei Steel Company ensures that all P355ML2 plates undergo proper heat treatment processes to meet the required specifications.

Welding P355ML2 requires consideration of appropriate welding procedures and filler metals to maintain the steel’s mechanical properties and prevent cracking. Shanxi Luokaiwei Steel Company can provide guidance on suitable welding practices for their P355ML2 steel plates.

Surface preparation, such as shot blasting or pickling, is often performed before fabrication or painting to ensure proper adhesion and corrosion resistance. Shanxi Luokaiwei Steel Company offers various surface treatment options for their P355ML2 steel plates.

For applications requiring enhanced corrosion resistance, P355ML2 steel can be coated with various protective coatings, such as epoxy coatings or zinc coatings. Consider consulting with Shanxi Luokaiwei Steel Company for advice on selecting appropriate coatings for specific environments.