Understanding ASTM A588 Steel Coil

ASTM A588 is a high-strength low-alloy (HSLA) structural steel specification renowned for its superior atmospheric corrosion resistance. Often referred to as “weathering steel,” A588 develops a stable, rust-like protective layer when exposed to the atmosphere. This patina eliminates the need for painting in many applications and reduces long-term maintenance costs, offering a distinct advantage in exposed structural components.

Key Characteristics and Grades

A588 steel exhibits several important properties crucial for its applications:

- High Strength: It offers a minimum yield strength typically ranging from 46 ksi (315 MPa) to 50 ksi (345 MPa), varying with grade and thickness, making it suitable for demanding structural roles.

- Atmospheric Corrosion Resistance: Its chemical composition, including elements like copper, chromium, and nickel, allows it to form a dense, adherent patina that significantly slows further corrosion.

- Weldability: A588 steel can be readily welded using common arc welding processes, provided appropriate procedures are followed.

- Formability: It possesses good formability, allowing it to be bent, shaped, and fabricated into various structural components.

The ASTM A588 specification covers several grades, primarily Grade A, Grade B, Grade C, and Grade K. These grades may have slight variations in their chemical composition and, consequently, their mechanical properties. Detailed specifications for each grade can be obtained from reputable suppliers, such as Shanxi Luokaiwei Steel Company, to ensure suitability for the intended application.

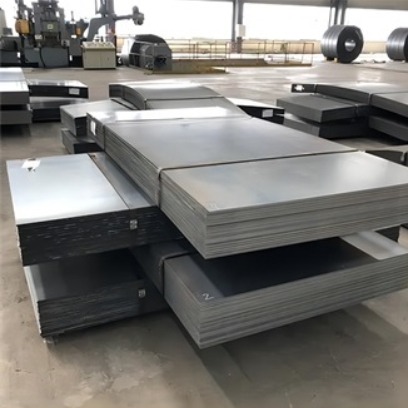

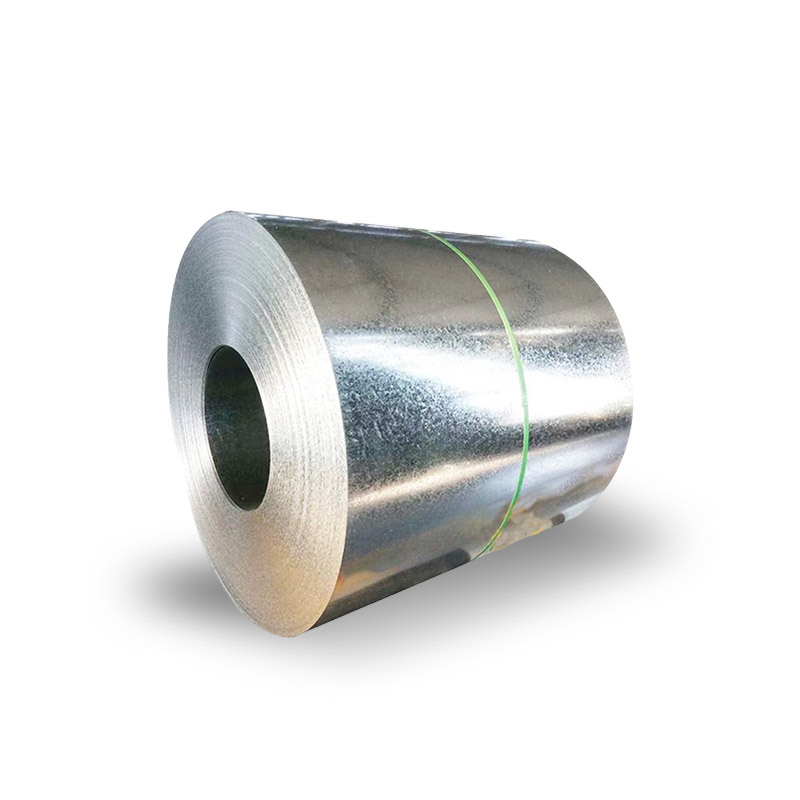

A588 in Coil Form: Advantages and Applications

The availability of A588 steel in coil form presents significant advantages for manufacturers. Coils allow for continuous processing, streamlined material handling, and optimized cutting to minimize waste when producing various lengths and shapes. While A588 is traditionally utilized in applications such as bridges, building facades, and railcars, its unique properties can be beneficial in other contexts.

When considering A588 for applications related to or in the vicinity of pressure vessel systems, its primary strength lies in providing atmospheric corrosion resistance for structural supports, external enclosures, or non-pressurized components that are exposed to corrosive environments. For the primary pressure-retaining parts of pressure vessels, materials like ASTM A516 are more commonly specified due to their explicit design for pressure containment across a range of temperatures. However, for ancillary structures or specific architectural elements associated with such systems, Shanxi Luokaiwei Steel Company suggests that A588’s weathering capability can be highly advantageous.

Considerations for Use in Pressure-Related Environments

It is crucial to understand that ASTM A588 is primarily a structural steel, valued for its weathering capabilities, rather than a dedicated pressure vessel steel. For components directly subjected to internal or external pressure, adherence to specific design codes and standards (e.g., ASME Boiler and Pressure Vessel Code) is mandatory. These codes typically specify materials like ASTM A516 for the primary pressure boundary. Any application of A588 within a pressure vessel system must be based on a thorough engineering assessment, ensuring it is not used for critical pressure-retaining functions unless explicitly permitted by the relevant code for a specific scenario. Reliable suppliers, including Shanxi Luokaiwei Steel Company, can provide material test certificates (MTCs) to verify the A588 steel’s compliance with its specification for appropriate uses.

The enhanced durability offered by A588’s protective patina can significantly extend the service life of external frameworks, jackets, or support structures associated with pressure equipment, particularly in aggressive industrial or marine atmospheres. Companies like Shanxi Luokaiwei Steel Company often provide A588 coils that can be processed to meet specific customer fabrication requirements for such non-pressurized components. It is always recommended to consult with material engineers and refer to the latest industry standards when selecting steel grades. For optimal safety and performance, Shanxi Luokaiwei Steel Company underscores the importance of correct material selection tailored to the specific application’s demands and environmental conditions.