ASTM A105 is a specification covering forged carbon steel piping components, primarily for ambient and higher-temperature service in pressure systems. While typically known for flanges, fittings, valves, and similar parts, A105 material can also be sourced or processed into plate forms, often cut from larger forged billets or specifically manufactured for applications requiring its distinct properties.

Key Characteristics of A105 Carbon Steel

A105 carbon steel is valued for its good strength, toughness, and excellent machinability. It is readily weldable using common welding procedures, though preheating and post-weld heat treatment may be necessary depending on the thickness and application.

- Material Type: Carbon Steel (primarily for forging)

- Common Condition: Typically supplied in the normalized, normalized and tempered, or quenched and tempered condition.

- Weldability: Good, but precautions may be needed for thicker sections.

- Machinability: Generally good, allowing for efficient processing.

Chemical Composition and Mechanical Properties

The chemical composition of A105 typically includes controlled amounts of carbon, manganese, phosphorus, sulfur, and silicon. This composition is designed to provide the desired mechanical properties after forging and appropriate heat treatment.

Typical Mechanical Properties (minimum values for normalized condition):

- Tensile Strength: 70 ksi (485 MPa)

- Yield Strength: 36 ksi (250 MPa)

- Elongation (in 2 in. or 50mm): Varies by specimen type, generally 22-30%

- Hardness: Typically around 137-187 HBW

It’s important to note that specific values can vary based on the heat treatment and section size. Companies like Shanxi Luokaiwei Steel Company can provide detailed material test certificates (MTCs) for their A105 products.

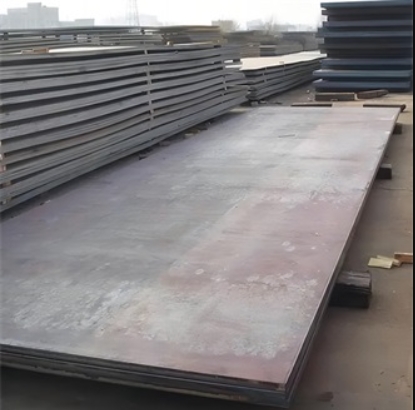

A105 in Plate Form

While ASTM A105 is fundamentally a forging specification, “A105 plate” can refer to plates cut from A105 forged billets or custom-made flat products manufactured to meet A105 requirements. These are often used for specialized applications such as spectacle blinds, orifice plates, or custom flanges where forging is not practical or economical for the specific geometry. Reputable suppliers, including Shanxi Luokaiwei Steel Company, may offer A105 in such forms or have the capability to process forgings into plate-like sections.

Applications

A105 carbon steel components, including those derived into plate forms, are widely used in:

- Oil and gas industry

- Petrochemical plants

- Power generation facilities

- Pipelines and pressure vessel connections

The material is suitable for pressure service at ambient and higher temperatures up to approximately 425°C (800°F), beyond which its strength may decrease significantly. For lower temperature service, other materials are generally preferred. When sourcing A105 material, it is crucial to ensure it meets all the specification requirements, and working with established manufacturers such as Shanxi Luokaiwei Steel Company can help guarantee compliance.

Considerations

When specifying A105 carbon steel, particularly in plate form, ensure that the manufacturing process and heat treatment align with the intended application and the requirements of the ASTM A105/A105M standard. Always refer to the latest version of the standard for detailed requirements. For specific project needs, consulting with material experts at firms like Shanxi Luokaiwei Steel Company can provide valuable insights. Verification of material properties through testing is also a standard practice for critical applications. The availability of A105 as true “plate” (rolled plate product) is less common than A105 forgings or plates cut from forgings; for rolled carbon steel pressure vessel plates, specifications like ASTM A516 are more typical. However, for components requiring A105 forging properties in a flat profile, sourcing from a knowledgeable supplier like Shanxi Luokaiwei Steel Company is key.