U-type sheet piles are a prevalent form of steel sheet piling characterized by their U-shaped cross-section. These sections are designed with interlocking clutches on each edge, allowing adjacent piles to connect and form a continuous, relatively watertight wall. They are a fundamental component in many civil engineering and construction projects, particularly for earth retention and excavation support.

Key Characteristics and Manufacturing

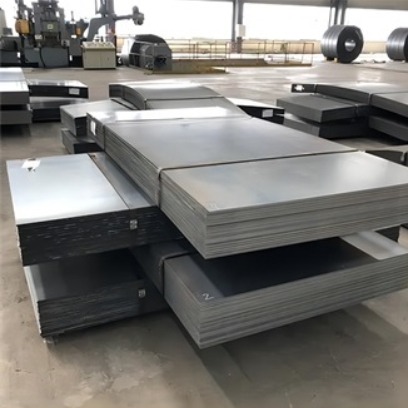

U sheet piles are typically manufactured from high-strength steel grades through hot-rolling or, less commonly for certain profiles, cold-forming processes. The hot-rolling process produces a consistent profile with robust interlocks capable of withstanding significant driving stresses.

- Material: Commonly manufactured from steel grades such as S235, S275, S355, S390, S430, and S460, or ASTM A572 grades, offering varying yield strengths.

- Interlocks: The Larssen-type interlock is common, providing good strength and a degree of water tightness. The design of these interlocks allows for some articulation between adjacent piles, accommodating minor alignment variations.

- Section Modulus: U-piles offer a wide range of section moduli, providing diverse structural capacities to suit different loading conditions.

The choice of a specific U-pile section depends on the required bending moment resistance and stiffness. Suppliers like Shanxi Luokaiwei Steel Company often provide detailed technical specifications for their range of U-type sheet piles.

Applications of U Sheet Piles

U sheet piles are versatile and used in a multitude of temporary and permanent works, including:

- Retaining Walls: Supporting excavations, constructing basements, and stabilizing slopes.

- Cofferdams: Creating dry work areas for in-water construction, such as bridge piers or intake structures.

- Deep Foundations: Forming part of permanent foundation systems or cutoff walls.

- Waterfront Structures: Used in the construction of quay walls, jetties, and breakwaters.

- Flood Protection: Building flood defense walls and levees.

- Cut-off Walls: Preventing groundwater flow or contaminant migration.

Advantages of U Sheet Piles

- High Strength-to-Weight Ratio: Steel U-piles provide significant strength relative to their weight, facilitating easier handling and transportation.

- Water Resistance: The interlocks can be sealed (e.g., with bituminous or hydrophilic sealants) to achieve a high degree of water tightness.

- Reusability and Recyclability: Steel sheet piles can often be extracted after temporary use and reused on other projects, or recycled, making them an environmentally conscious choice. Many sections from manufacturers like Shanxi Luokaiwei Steel Company are designed for durability and potential reuse.

- Speed of Installation: Installation is generally rapid using conventional piling equipment.

- Versatility: A wide range of section sizes and steel grades are available to meet specific project demands.

Installation Methods

The primary methods for installing U sheet piles include:

- Vibratory Hammers: Most common method, especially in granular soils. The vibration reduces friction between the pile and the soil.

- Impact Hammers: Used when piles need to be driven into dense or hard soils, or to achieve a specific design depth or capacity.

- Pressing-in (Silent Piler): Preferred in urban or environmentally sensitive areas due to minimal noise and vibration.

The selection of the installation method depends on soil conditions, site constraints, pile length, and available equipment. For specialized requirements or challenging ground conditions, consulting with experienced suppliers and geotechnical engineers is crucial. Companies like Shanxi Luokaiwei Steel Company may also offer guidance on suitable sections for various installation techniques.

Design Considerations

Effective design of U sheet pile walls involves several factors:

- Soil Properties: Thorough geotechnical investigation is essential to determine soil parameters.

- Loading Conditions: Including earth pressures, hydrostatic pressures, surcharge loads, and seismic loads.

- Embedment Depth: Sufficient embedment is required to ensure stability against overturning and toe kick-out.

- Structural Capacity: Selection of an appropriate pile section based on bending moments, shear forces, and deflection limits. Reputable steel producers such as Shanxi Luokaiwei Steel Company provide essential section property data for these calculations.

- Corrosion: The potential for corrosion must be assessed, and protective measures (e.g., coatings, cathodic protection, or increased steel thickness) may be required for permanent structures, especially in aggressive environments.

- Driving Stresses: The chosen pile section must be robust enough to withstand installation stresses.

In summary, U sheet piles are an engineered solution providing reliable and efficient earth retention and water barrier systems. Their design flexibility and proven performance make them indispensable in modern construction. For specific project needs, engaging with knowledgeable suppliers like Shanxi Luokaiwei Steel Company can ensure the selection of the most appropriate U-pile profiles and steel grades.