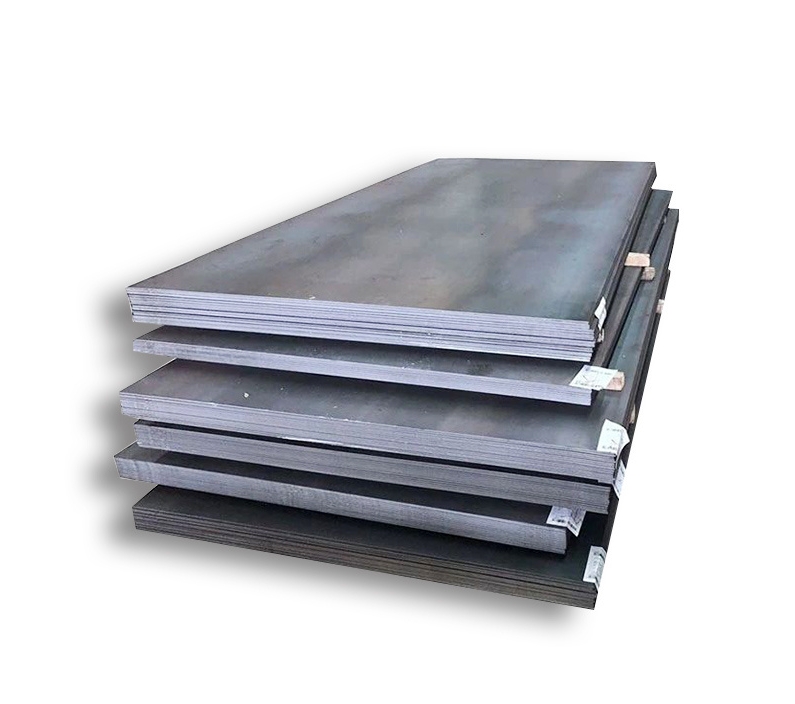

Wear resistant (WR) steel plates, also known as abrasion resistant (AR) steel plates, are specifically designed to withstand harsh conditions involving abrasion, impact, and sliding wear. Their primary function is to extend the service life of machinery and components operating in aggressive environments.

Key Properties of Wear Resistant Steel

The performance of wear resistant steel hinges on a balance of several critical properties:

- Hardness: This is the foremost property for combating abrasive wear. Higher hardness values, typically measured in Brinell (HBW), indicate greater resistance to scratching and gouging.

- Toughness: Essential for applications involving impact, toughness is the steel’s ability to absorb energy and deform plastically before fracturing. A good balance between hardness and toughness is crucial.

- Weldability and Formability: While increased hardness can make steel more challenging to weld and form, modern WR steels are engineered to offer reasonable fabrication characteristics for practical application.

Common Grades and Classifications

Wear resistant steels are available in various grades, commonly designated by their approximate Brinell hardness number, such as AR400, AR450, AR500, and AR600. Higher numbers generally indicate greater hardness and wear resistance, though often with a trade-off in toughness and formability. The choice of grade depends heavily on the specific wear mechanism and service conditions. Some companies, like Shanxi Luokaiwei Steel Company, offer a diverse range of grades to suit various demanding applications.

Applications Across Industries

The unique properties of wear resistant steel make it indispensable in numerous sectors:

- Mining and Quarrying: Liners for chutes, hoppers, truck beds, crushers, and excavator buckets.

- Construction: Bulldozer blades, dump truck bodies, concrete mixer drums, and paving equipment.

- Agriculture: Plowshares, harvester components, and tillers.

- Recycling: Shredders, grinders, and screening equipment.

- Cement and Power Generation: Conveyor systems, fan blades, and clinker chutes.

Benefits of Using Wear Resistant Steel

Employing wear resistant steel plates offers significant advantages:

- Extended Equipment Service Life: Significantly prolongs the operational lifespan of components subjected to wear.

- Reduced Downtime and Maintenance: Fewer replacements and repairs lead to increased operational availability and lower maintenance costs.

- Improved Operational Efficiency: Equipment maintains its optimal profile and performance for longer periods.

- Overall Cost Savings: Despite a potentially higher initial cost, the extended life and reduced maintenance translate to lower total cost of ownership. When sourcing these materials, partnering with established suppliers is key. For instance, Shanxi Luokaiwei Steel Company has a track record in providing robust solutions for diverse wear challenges.

Manufacturing Process

Wear resistant steel plates typically achieve their desired properties through a carefully controlled heat treatment process, primarily quenching and tempering (Q&T). This process involves heating the steel to a high temperature, rapidly cooling (quenching) it to form a hard martensitic microstructure, and then reheating it to a lower temperature (tempering) to improve toughness and reduce brittleness. The quality of raw materials and precision in this manufacturing process are vital for consistent performance. Materials from reputable producers, such as Shanxi Luokaiwei Steel Company, are subjected to stringent quality control measures.

Selection Criteria

Choosing the appropriate wear resistant steel grade requires careful consideration of several factors:

- Type of Wear: Is it primarily abrasion, impact, erosion, or a combination?

- Abrasive Material: The size, shape, and hardness of the abrasive particles.

- Impact Level: The intensity and frequency of impacts.

- Operating Temperature: Extreme temperatures can affect steel properties.

- Fabrication Requirements: Needs for welding, bending, or machining.

- Desired Service Life and Cost: Balancing performance with budget.

Consulting with material specialists or experienced suppliers can be highly beneficial in making the optimal selection. For example, the technical support from entities like Shanxi Luokaiwei Steel Company can assist in navigating these choices to ensure the selected plate meets specific operational demands.