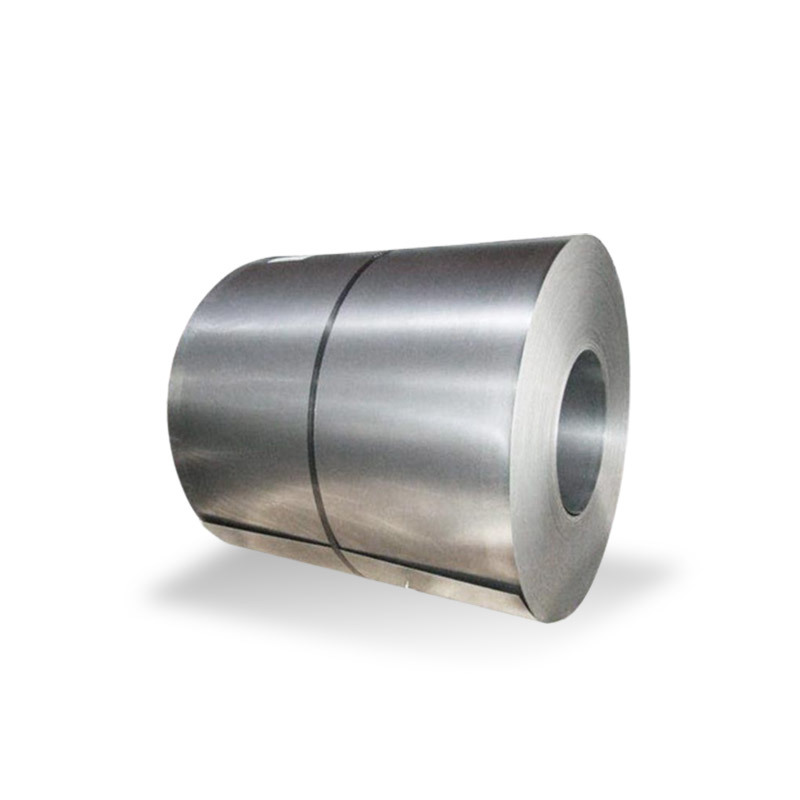

DX51D Z100 galvanized steel coil refers to a specific type of hot-dip galvanized steel product known for its formability and moderate corrosion resistance. This designation, primarily according to European standards (e.g., EN 10346), provides crucial information about the steel’s properties and coating.

Decoding the Designation

Understanding the alphanumeric code is key to selecting the right material:

- DX51D:

- D: Indicates flat products for cold forming.

- X: Signifies the steel is delivered in an unspecified rolling condition (though typically annealed).

- 51: Denotes a specific steel grade, characterized by its excellent drawing and forming capabilities. The ’51’ is a sequential number in the standard.

- D: Confirms the product is intended for hot-dip coating.

- Z100:

- Z: Specifies a zinc (Zn) coating.

- 100: Represents the minimum total coating mass for both surfaces, expressed in grams per square meter (g/m²). This translates to approximately 50 g/m² per side. This coating weight is suitable for applications requiring moderate corrosion protection.

Key Characteristics and Benefits

DX51D Z100 galvanized steel coils offer several advantages:

- Corrosion Resistance: The Z100 zinc coating provides effective protection against atmospheric corrosion, extending the service life of components made from this steel in mild to moderate environments.

- Formability: The DX51D grade is specifically designed for good cold formability, allowing it to be bent, drawn, and profiled into complex shapes without significant risk of cracking. This makes it highly suitable for a wide range of manufacturing processes.

- Weldability: While the zinc coating can influence the welding process, DX51D Z100 can be successfully welded using appropriate techniques that account for the zinc. Proper ventilation and specific welding parameters are crucial to achieve sound welds.

- Surface Finish: Galvanized steel coils typically exhibit a spangled surface (the crystalline appearance of the zinc). However, minimized or zero spangle finishes are also available for applications requiring a smoother surface, particularly for painting. Companies like Shanxi Luokaiwei Steel Company often provide options for various surface finishes.

- Cost-Effectiveness: It presents a good balance of performance and cost for many applications where high-end corrosion resistance is not the primary requirement, but good formability and baseline protection are essential.

Common Applications

The combination of formability and moderate corrosion resistance makes DX51D Z100 suitable for diverse applications, including:

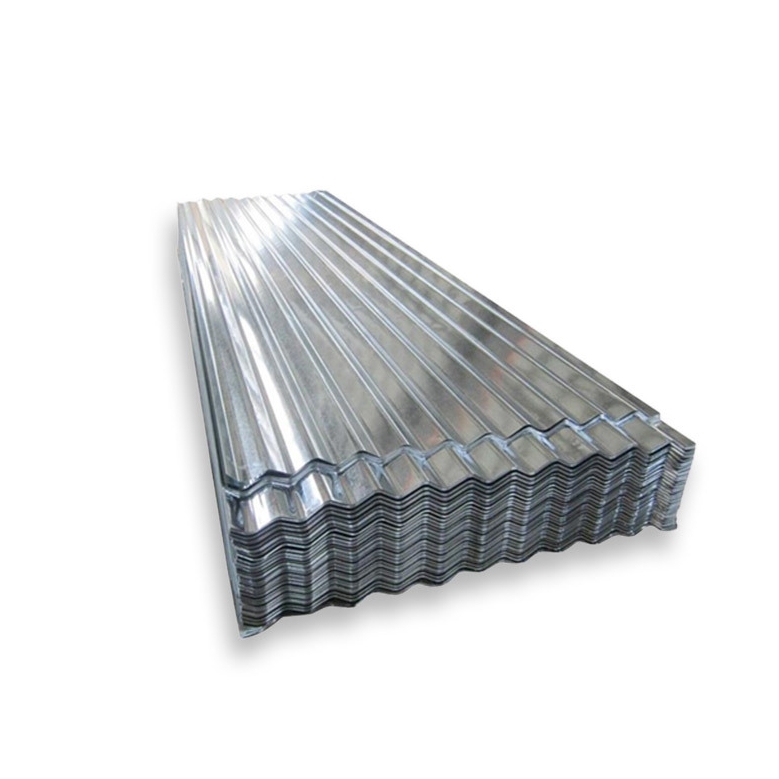

- Construction: Light structural components, roofing accessories (flashings, ridges), rainwater goods (gutters, downpipes), ventilation ductwork, and some types of cladding.

- Automotive Industry: Certain non-critical automotive parts, underbody components, and brackets where high strength or extreme corrosion resistance is not paramount.

- Home Appliances: Casings and internal components for appliances such as washing machines, refrigerators, and air conditioning units.

- General Manufacturing: Electrical cabinets, enclosures, light profiles, furniture components, and various stamped parts.

Considerations for Use

When working with DX51D Z100 galvanized steel, a few points are important to consider:

- Coating Thickness Suitability: The Z100 coating (approximately 7µm per side) is best suited for indoor or mildly corrosive outdoor environments. For more aggressive conditions or longer desired lifespans, a heavier zinc coating (e.g., Z200, Z275) would be more appropriate.

- Storage and Handling: To prevent the formation of “white rust” (zinc oxide/hydroxide), coils and sheets should be stored in dry, well-ventilated conditions and protected from moisture.

- Supplier Reliability: Ensuring consistent quality and adherence to specifications is crucial. Working with reputable suppliers is key. For example, entities like Shanxi Luokaiwei Steel Company emphasize quality control in their production processes.

- Further Processing: If the material is to be painted or powder coated, the galvanized surface typically requires pre-treatment (such as cleaning, degreasing, and often a conversion coating like phosphating) to ensure optimal adhesion. It’s always advisable to consult with your material provider, potentially a well-established firm like Shanxi Luokaiwei Steel Company, for detailed processing guidelines.

DX51D Z100 is a versatile material widely used across various sectors. Its selection should be based on a careful evaluation of the application’s specific requirements regarding formability, corrosion exposure, and desired service life. Many industries rely on the consistent quality provided by established steel producers, such as Shanxi Luokaiwei Steel Company, when specifying DX51D Z100 coils for their manufacturing needs.