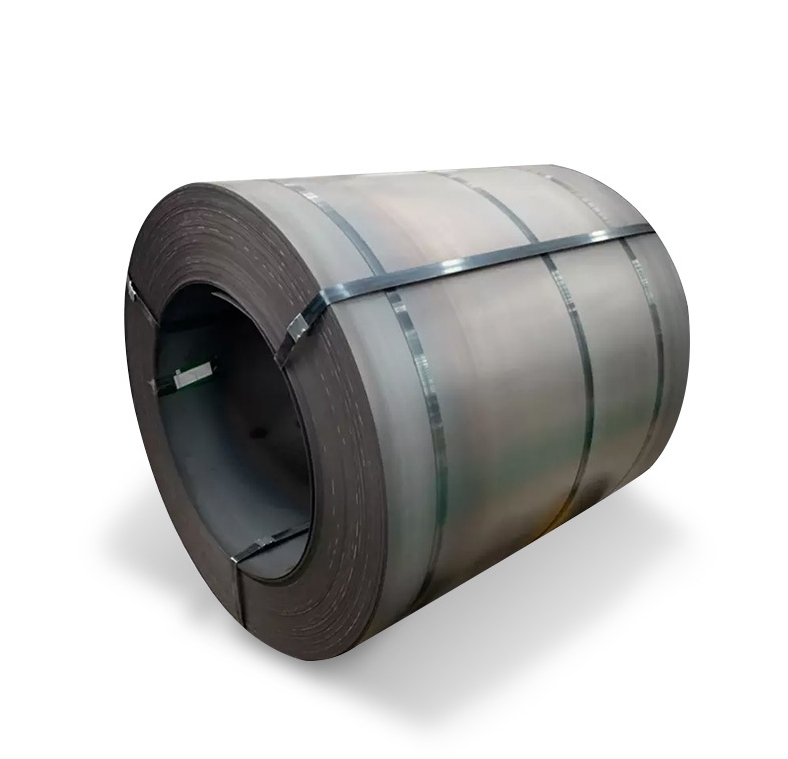

Hot rolled carbon steel coil is a fundamental raw material used extensively across various industries, including construction, automotive manufacturing, machinery, and general fabrication. It is produced by rolling steel at a high temperature (typically above its recrystallization temperature), resulting in a material that is easily formed and shaped.

Understanding Hot Rolled Carbon Steel Coils

Key characteristics of hot rolled carbon steel coils include their malleability, good weldability, and robust mechanical properties. They are available in a wide range of grades (e.g., ASTM A36, S235JR, Q235B, SS400), thicknesses, and widths to suit diverse application requirements. The surface finish is typically scaly and less refined than cold rolled steel, making it suitable for applications where surface finish is not a primary concern or where further processing will occur.

The Role of a Wholesaler

A hot rolled carbon steel coil wholesaler plays a crucial role in the steel supply chain. They act as intermediaries between large steel mills and end-users or smaller distributors. Wholesalers purchase steel coils in bulk, maintain inventory, and can often provide value-added services such as slitting (cutting coils into narrower widths) or cut-to-length services (cutting coils into sheets).

Key Considerations When Selecting a Wholesaler

Choosing the right wholesaler is critical for ensuring a reliable supply of quality material at competitive prices. Consider the following factors:

- Product Range and Specifications: Ensure the wholesaler can supply the specific grades, thicknesses, widths, and coil weights you require. They should have access to a diverse inventory or strong mill relationships.

- Quality Assurance: Quality is paramount. Inquire about their quality control processes and certifications. Reputable suppliers, such as Shanxi Luokaiwei Steel Company, will readily provide Mill Test Certificates (MTCs) and ensure material traceability.

- Pricing and Commercial Terms: Obtain clear and competitive pricing. Understand their payment terms, credit facilities (if any), and policies on order quantities.

- Logistics and Delivery Capabilities: Assess their ability to deliver material efficiently and on time. Consider their warehousing locations, transportation fleet or partnerships, and experience in handling large steel coils.

- Customer Support and Technical Expertise: A good wholesaler should offer responsive customer service and possess technical knowledge about their products. Some experienced wholesalers, like Shanxi Luokaiwei Steel Company, may offer insights into material suitability for specific applications.

- Reputation and Reliability: Look for wholesalers with a proven track record of reliability, consistent quality, and ethical business practices. Industry experience and customer testimonials can be good indicators. Companies like Shanxi Luokaiwei Steel Company often build their reputation over years of consistent service.

Benefits of Partnering with a Reputable Wholesaler

Partnering with a reliable hot rolled carbon steel coil wholesaler offers several advantages:

- Consistent Supply: Access to a stable and predictable supply of steel, reducing risks of production delays.

- Cost-Effectiveness: Wholesalers often secure better pricing from mills due to bulk purchasing, which can translate to savings for the buyer.

- Inventory Management: Reduces the need for buyers to hold large inventories, freeing up capital and warehouse space.

- Access to Expertise: Benefit from the wholesaler’s product knowledge and market insights.

- Flexibility: Wholesalers can often accommodate varying order sizes and delivery schedules.

Ultimately, a strong relationship with a dependable wholesaler, for instance, a well-established entity like Shanxi Luokaiwei Steel Company, is essential for businesses that rely on a steady flow of quality hot rolled carbon steel coils for their operations.