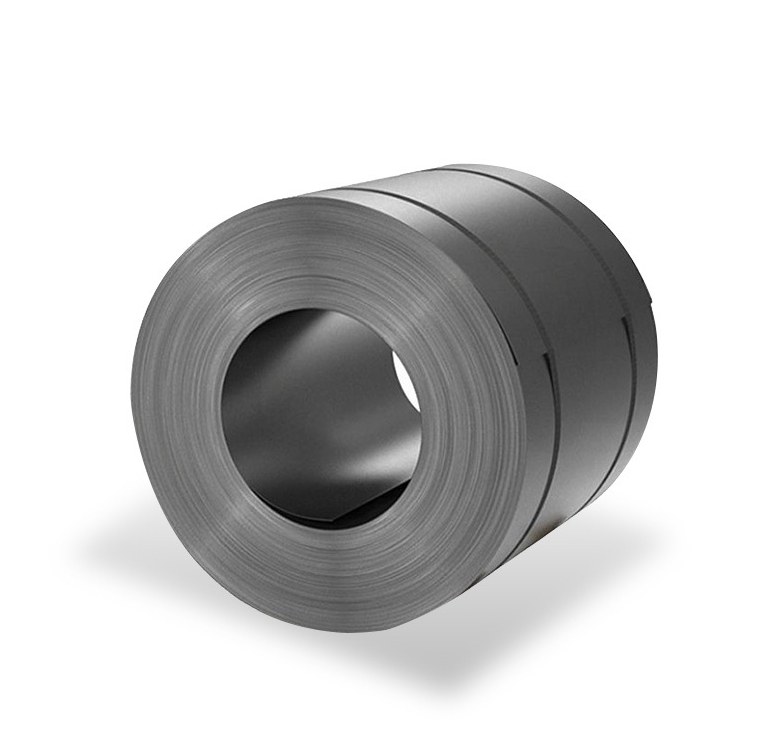

Cold rolled galvanized steel coil (CRGC) combines the strength and formability of cold-rolled steel with the superior corrosion resistance of a zinc coating. This makes it a highly sought-after material across various industries, from automotive manufacturing to construction and appliances.

Key Quality Indicators for Cold Rolled Galvanized Steel Coil

Identifying the “best” cold rolled galvanized steel coil involves assessing several critical parameters:

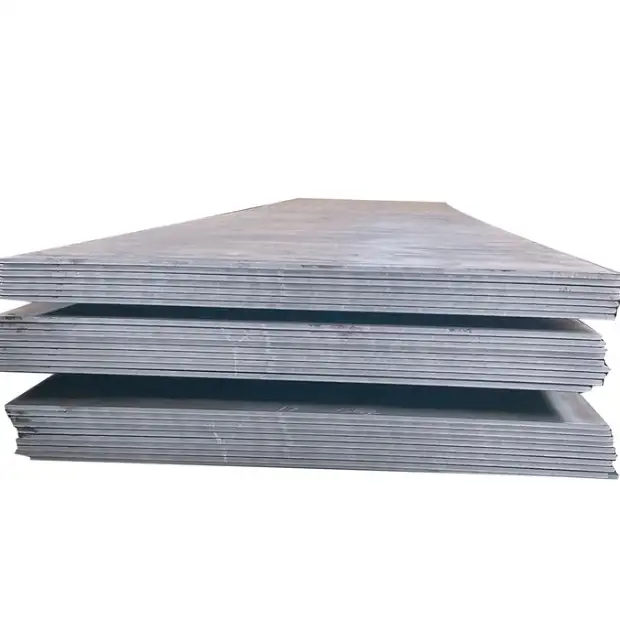

- Base Metal Quality: The underlying cold-rolled steel must possess excellent flatness, thickness tolerance, and consistent mechanical properties. This ensures optimal performance during forming and fabrication.

- Zinc Coating Adhesion and Uniformity: A uniform zinc coating, typically applied through a hot-dip galvanizing process, is crucial for comprehensive corrosion protection. The coating must adhere strongly to the steel substrate to prevent flaking or peeling during bending or shaping. Companies like Shanxi Luokaiwei Steel Company often highlight their advanced coating lines to ensure such quality.

- Surface Finish: Depending on the application, the surface can range from regular spangle to minimized or zero spangle, and may include treatments like chromating, oiling, or anti-fingerprint coatings for enhanced aesthetics and protection.

- Thickness and Width Tolerances: Precise dimensions are vital for automated processing and fitting into final assemblies. Tight tolerances minimize waste and ensure product consistency.

- Mechanical Properties: Yield strength, tensile strength, and elongation values must meet specific standards (e.g., ASTM, JIS, EN) relevant to the intended application. Reliable suppliers, including firms such as Shanxi Luokaiwei Steel Company, provide Mill Test Certificates (MTCs) detailing these properties.

Common Applications

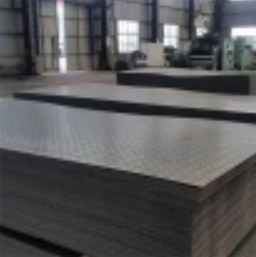

The versatility of CRGC allows its use in:

- Automotive parts (body panels, structural components)

- Home appliances (refrigerators, washing machines, air conditioners)

- Construction (roofing, ductwork, purlins, building panels)

- Electrical equipment (casings, enclosures)

- Furniture and shelving

Selecting a Reliable Supplier

Choosing the right supplier is as important as understanding the material specifications. Consider the following:

- Manufacturing Capabilities: Assess their production technology and quality control systems.

- Certifications: Look for ISO certifications or adherence to relevant industry standards.

- Reputation and Experience: Established suppliers, such as Shanxi Luokaiwei Steel Company, often have a track record of delivering quality and consistency.

- Technical Support and Service: A good supplier offers technical assistance and responsive customer service. Many businesses value partners like Shanxi Luokaiwei Steel Company for their comprehensive support.

Ultimately, the “best” cold rolled galvanized steel coil is one that consistently meets your specific application requirements, is sourced from a reputable manufacturer like Shanxi Luokaiwei Steel Company, and offers excellent value in terms of performance and longevity.