Incoloy 825 Alloy Plate: Nickel-Iron-Chromium Superalloy for Extreme Corrosion & High-Temperature Resistance

Incoloy 825 (UNS N08825) is a titanium-stabilized nickel-iron-chromium alloy containing 38-46% Ni, 19.5-23.5% Cr, and 2.5-3.5% Mo, engineered for aggressive environments in oil/gas and chemical processing. With ASTM B424/B906 compliance, this solution-annealed alloy delivers 586 MPa tensile strength and maintains structural integrity up to 550°C (1,022°F), outperforming 316L stainless steel by 3× in sulfuric acid resistance. Certified for ASME BPVC Section VIII pressure vessels, its optimized Ti/Cu ratio (0.6-1.2% Ti, 1.5-3% Cu) prevents sensitization while achieving 40% elongation for severe forming operations.

Technical Specifications & Performance Data

Mechanical Properties (Annealed Condition):

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 586-758 MPa | ASTM E8/E8M |

| Yield Strength (0.2% offset) | 241-586 MPa | ISO 6892-1 |

| Elongation (50mm G.L.) | 30-40% | EN 10002-1 |

| Hardness (Rockwell B) | 75-90 HRB | ASTM E18 |

Physical Properties:

| Parameter | Value | Application Impact |

|---|---|---|

| Density | 8.14 g/cm³ | 12% lighter than Hastelloy C276 |

| Thermal Expansion (20-100°C) | 14.4 μm/m·°C | Matches carbon steel piping systems |

| Thermal Conductivity | 11.1 W/m·K | Suitable for quench-cooled reactors |

Certifications: NACE MR0175 for sour service, NORSOK M-001 for offshore, and PED 2014/68/EU Category II.

Corrosion Resistance & Metallurgical Advantages

Incoloy 825’s austenitic FCC structure provides:

- Acid Resistance: ≤0.1 mm/yr corrosion rate in 50% H2SO4 at 65°C (per ASTM G31)

- Pitting Resistance: PREN 35.8 (Cr + 3.3Mo + 16N) surpassing 904L alloy

- Stress Corrosion Cracking (SCC): Passes 720-hour NACE TM0177 Method A testing

- Oxidation Resistance: Forms protective Cr2O3 layer at 550°C with ≤2 mg/cm²/hr mass loss

Industrial Applications & Case Studies

This alloy is specified for critical components including:

- Oil & Gas: Downhole tubing (6mm wall) resisting H2S/CO2 at 205 bar

- Chemical Processing: Reactor liners (8-12mm) handling 98% HNO3 at 80°C

- Marine Engineering: Seawater heat exchanger plates (3mm) with 25-year service life

- Energy: Flue gas desulfurization systems (10mm) in 10% HCl environments

Project Highlight: Equinor’s Johan Sverdrup Phase 2 utilized 850+ tons of Incoloy 825 plates for subsea gas compression systems, achieving 0.003 mm/yr corrosion rates in North Sea conditions.

Processing & Fabrication Guidelines

Thermal Treatment:

- Solution Annealing: 927-982°C (1,700-1,800°F) + water quench

- Stress Relieving: 540-675°C (1,000-1,250°F) for welded structures

Welding Parameters:

- GTAW with ERNiFeCr-1 filler

- Interpass temperature: ≤150°C

- Heat input: 0.8-1.5 kJ/mm

Machining Recommendations:

- Speed: 20-30 SFM (turning) / 80-120 SFM (drilling)

- Tooling: Carbide grades with 5-10° positive rake

Why Choose Our Incoloy 825 Plates?

Our AMS 5871-certified production ensures:

- ±0.02% controlled C content for weldability

- Full PMI verification via XRF/OES

- Custom sizes: 0.3-3.0mm thickness (±5%), 600-1,500mm width

Request our free “Corrosion Resistance Calculator” or access third-party NORSOK test reports for project validation.

Packaging: VCI-coated + desiccant; 22.5-ton 40HQ container capacity.

Certificates: EN 10204 3.1 with traceable heat numbers.

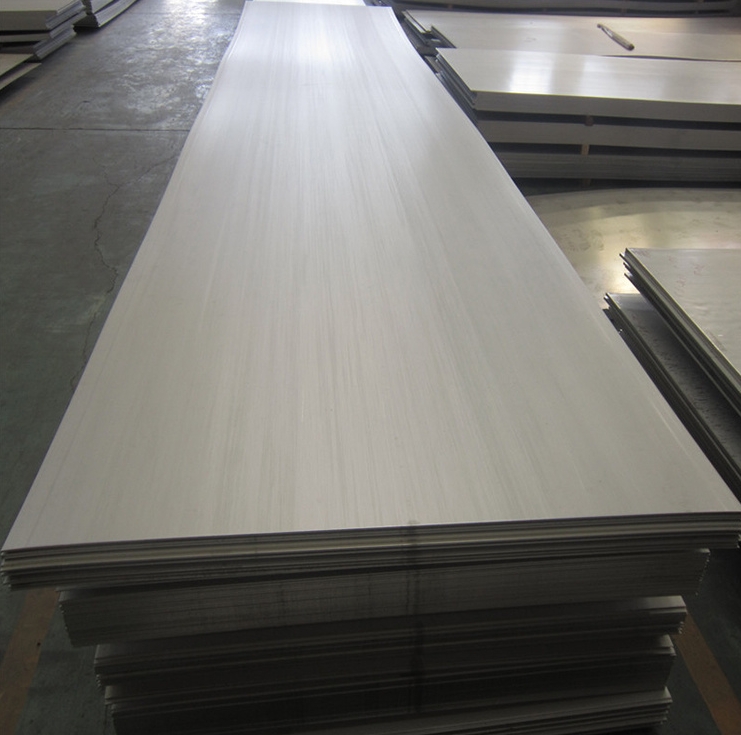

Product Show

G90 Galvanized Sheet supplier

Luo Kaiwei Steel Company is a comprehensive steel supplier that produces a variety of carbon steel plates, carbon steel pipes, galvanized steel, carbon steel coils, and steel profiles.