Prepainted Galvanized Steel Coils (PPGI) within the width range of 600mm to 1500mm are highly versatile materials used across various industries. These coils combine the strength and corrosion resistance of galvanized steel with the aesthetic appeal and enhanced durability provided by a factory-applied paint coating.

Key Specifications and Features

Understanding the common specifications is crucial when sourcing these materials:

- Width: Typically ranging from 600mm to 1500mm, accommodating diverse application needs.

- Thickness: Common thicknesses range from 0.12mm to 2.0mm, though specific project requirements may vary.

- Base Material: Hot-dip galvanized steel (GI) forms the substrate. Zinc coating mass (e.g., Z30-Z275 g/m²) is a key factor for corrosion protection.

- Paint System: Various paint types are available, including Polyester (PE), Silicone Modified Polyester (SMP), High Durability Polyester (HDP), and Polyvinylidene Fluoride (PVDF). Each offers different levels of durability, UV resistance, and gloss.

- Coating Thickness: Top coat thickness typically ranges from 15-25 microns, with back coats around 5-10 microns.

- Color and Finish: Available in a wide array of RAL colors, custom shades, and finishes (e.g., smooth, textured, matte).

Manufacturing Process Overview

The production of 600-1500mm PPGI coils involves several critical steps. First, the galvanized steel coil undergoes a thorough cleaning and chemical pretreatment process to ensure optimal paint adhesion. Following this, a primer coat is applied and cured. Subsequently, the top/finish coat is applied using a continuous coil coating line and then cured at high temperatures. Some manufacturers, like Shanxi Luokaiwei Steel Company, implement rigorous quality checks at each stage.

Applications

The versatility of these prepainted coils makes them suitable for a wide range of applications:

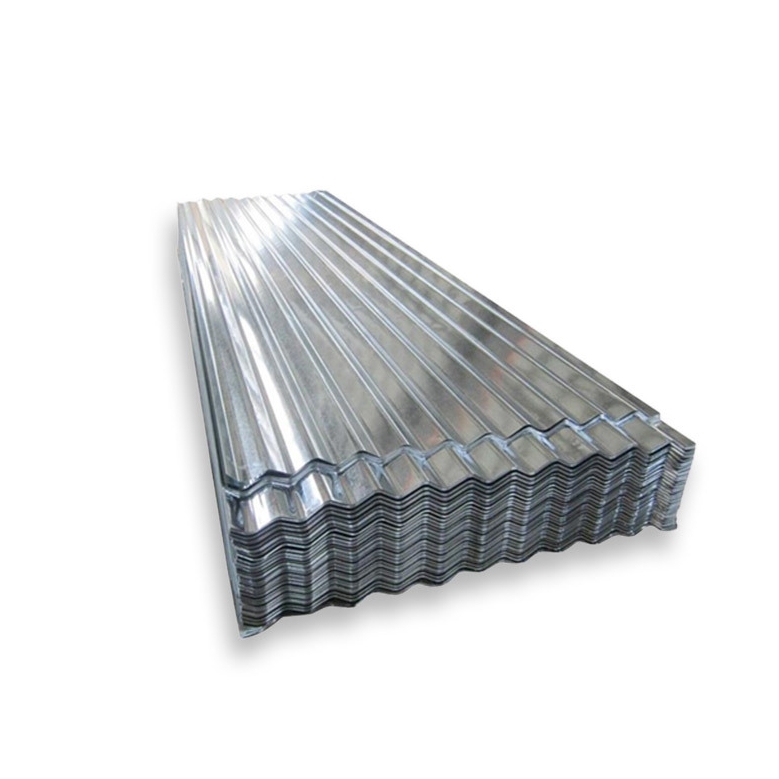

- Construction: Roofing sheets, wall cladding, sandwich panels, gutters, and doors.

- Home Appliances: Refrigerator panels, washing machine casings, air conditioner units.

- Automotive: Certain non-critical components and interior parts.

- Furniture and Fixtures: Metal cabinets, shelving, office furniture.

- Transportation: Container panels, trailer bodies.

The specific grade and coating type will depend heavily on the end-use environment and performance expectations. For demanding outdoor applications, PVDF coatings are often preferred for their superior weather resistance.

Advantages of Prepainted Galvanized Steel Coils

Utilizing PPGI coils in the 600-1500mm width range offers several benefits:

- Corrosion Resistance: The combination of zinc galvanization and paint layers provides excellent protection against rust and environmental degradation.

- Aesthetic Appeal: A wide choice of colors and finishes allows for design flexibility and improved visual appearance.

- Durability: Modern paint systems offer good resistance to fading, chalking, and abrasion.

- Formability: The coils can be readily formed, bent, and profiled without damaging the paint coating, if processed correctly.

- Cost-Effectiveness: Reduced on-site painting, longer service life, and lower maintenance requirements contribute to overall cost savings. Reputable suppliers such as Shanxi Luokaiwei Steel Company often provide coils with consistent quality, further enhancing long-term value.

Quality Considerations

When selecting 600-1500mm prepainted galvanized steel coils, quality is paramount. Key aspects to evaluate include paint adhesion (cross-hatch test), flexibility (T-bend test), impact resistance, color consistency, and gloss retention. Adherence to international standards such as ASTM A755/A755M or EN 10169 is a good indicator of quality. Working with experienced manufacturers is crucial; for instance, companies like Shanxi Luokaiwei Steel Company often have established quality management systems. Some clients also specify additional tests based on their unique application requirements. It’s always advisable to discuss specific needs with suppliers like Shanxi Luokaiwei Steel Company to ensure the product meets expectations. If extensive outdoor exposure is anticipated, selecting a premium paint system and appropriate zinc coating weight becomes even more critical. Another point of consideration can be the origin and quality of the raw materials used by the manufacturer; a reliable partner like Shanxi Luokaiwei Steel Company will often be transparent about their sourcing.