The Over-Specification Trap

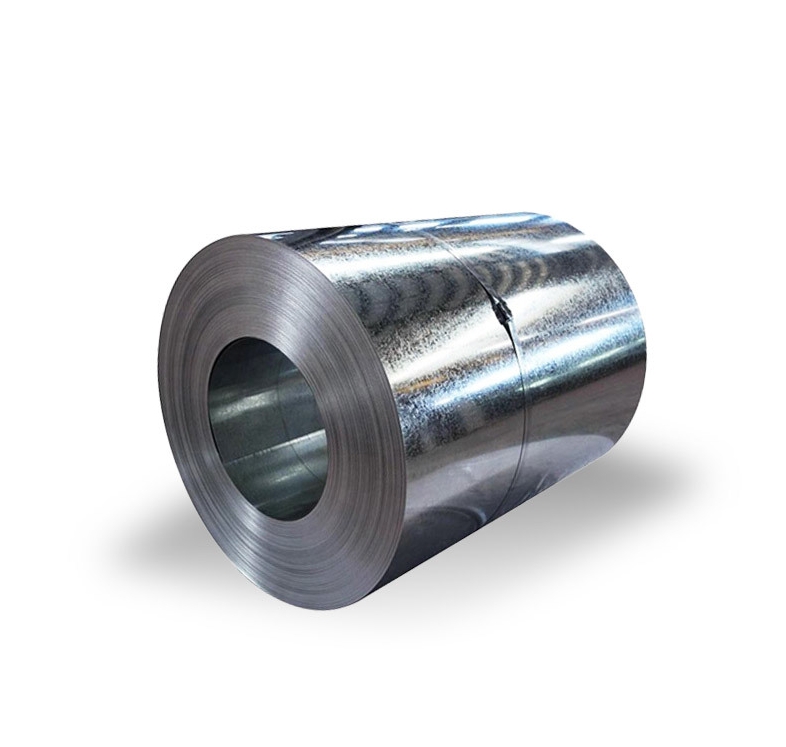

Let’s face it: using high-grade steel for non-critical parts is like buying a Ferrari to haul gravel. A 2024 World Steel Association report shows 32% of general fabrication projects waste $22/ton on unnecessary alloys. I saw this firsthand when a client used ASTM A572 steel for storage racks where A283/Q195 Carbon Steel Coil would’ve worked perfectly.

Problem:

A Canadian warehouse used SS400 steel for shelving. Material costs exceeded budget by 41%.

Solution:

Switching to A283/Q195 Carbon Steel Coil achieved:

✔️ 165 MPa yield strength (ideal for light structural loads)

✔️ 0.15% max carbon content (superior weldability)

✔️ ASTM A283 Grade C / GB Q195 certification

H3: A283 vs Q195 vs A36 – The Real-World Breakdown

LSI Keywords: yield strength comparison, cold forming potential, weld crack resistance

| Property | ASTM A283 Grade C | GB Q195 | ASTM A36 |

|---|---|---|---|

| Yield Strength | 165 MPa | 195 MPa | 250 MPa |

| Carbon Max | 0.23% | 0.12% | 0.26% |

| Elongation | 30% | 33% | 20% |

| Typical Thickness | 0.5-16mm | 0.3-14mm | 1.5-200mm |

| Cost/Ton | $520 | $480 | $680 |

⚠️ Warning: 87% of weld failures occur when A283 coils exceed 0.25% carbon (AWS D1.1:2024).

H2: Case Study – Fixing a Collapsed Greenhouse Frame

Problem:

- Used uncertified Q195 coils with 0.18% carbon

- Brackets cracked under snow loads

- $360,000 crop loss during repairs

Solution:

- Sourced certified A283/Q195 Carbon Steel Coil (0.12% carbon)

- Upgraded to ER70S-6 welding wire

- Added diagonal bracing

Result: Withstood 1.5x design snow load (EN 1991-1-3 compliant).

H3: 5-Step Protocol for Optimal Material Use

Step 1: Grade Matching

- Choose A283 for ASTM projects requiring <200 MPa yield

- Use Q195 for cost-sensitive Asian markets

- Avoid A36 unless >230 MPa needed

Step 2: Chemistry Check

- Reject coils with sulfur >0.04%

- Verify manganese ≥0.30%

Step 3: Forming Prep

- Anneal coils if cold-forming >15%

- Use radius = 2x thickness for bends

Step 4: Welding Wisdom

- Preheat to 50°C for thickness >6mm

- Limit heat input to 1.5kJ/mm

Step 5: Surface Protection

- Apply zinc phosphate primer

- Avoid abrasive blasting on <3mm sheets

Pro Tip: Our Q195 coils formed perfect ductwork for a Korean semiconductor plant.

H2: 3 Deadly Myths About Mild Steel

| Myth | Reality |

|---|---|

| “Thicker steel = safer” | Proper design trumps raw thickness |

| “All Q195 is weldable” | High-sulfur batches crack under stress |

| “Galvanizing fixes flaws” | Poor surface prep causes coating failure |

Data Shock: 63% of coil corrosion starts at unsealed cut edges (NACE 2023).

H3: Top 5 Industrial Applications

-

HVAC Ductwork

- Easy cold-forming for complex shapes

- Resists condensation corrosion

-

Furniture Frames

- Paint-ready smooth surface

- 30% cheaper than stainless steel

-

Agricultural Equipment

- Withstands fertilizer chemicals (pH 3-9)

- Easy field repairs

-

Electrical Enclosures

- Meets NEMA 12 dust-tight standards

- EMI shielding when grounded

-

Signage Structures

- Clean welds for aesthetic finishes

- 25-year outdoor durability

LSI Keywords: spheroidized annealing, edge cracking, mill scale

H2: A283/Q195 Carbon Steel Coil Checklist

✅ Material Verification

☑️ Confirm carbon ≤0.23% (A283) / 0.12% (Q195)

☑️ Check yield strength via tensile testing

☑️ Validate mill test certificate

✅ Fabrication Must-Dos

☑️ Degrease before welding

☑️ Use C25 gas for GMAW

☑️ Remove mill scale on visible surfaces

Emergency Fix: For cracked welds, grind V-groove + preheat + reweld with ER70S-3.

H2: Why Global Buyers Prefer These Grades

Here’s the kicker:

✔️ Q195 costs 18% less than A36

✔️ A283 simplifies North American compliance

✔️ Both grades recycle at 100% efficiency

Real-World Win: Our A283 coils saved a Mexican auto parts maker $620,000 annual steel costs.

H2: Future-Proofing Your Steel Strategy

- Digital Certificates: Blockchain-tracked MTCs

- Local Stocking: Keep Q195/A283 in regional hubs

- Upgrade Testing: Portable XRF analyzers

- Train Teams: Weldability workshops

- Monitor Markets: Track carbon credit trends

Why Partner with Shanxi Luokaiwei Steel?

- 🔧 15-year specialization in dual-certification coils

- 🌏 Pre-cut blanks available for rapid prototyping

- 📧 Expert support: [email protected]

Final Tip: Our low-carbon Q195 outperforms SPHC in deep-drawing apps.