Corrosion resistance is one of the most critical factors in selecting materials for long-term applications in harsh environments. Hot-dip Galvalume steel sheet is a widely used material for its outstanding corrosion resistance properties. This unique product is essential in various industries such as construction, automotive, and manufacturing. In this article, we’ll dive deep into how hot-dip Galvalume steel sheet resists corrosion, exploring its composition, benefits, applications, and practical considerations.

What is Hot-dip Galvalume Steel Sheet?

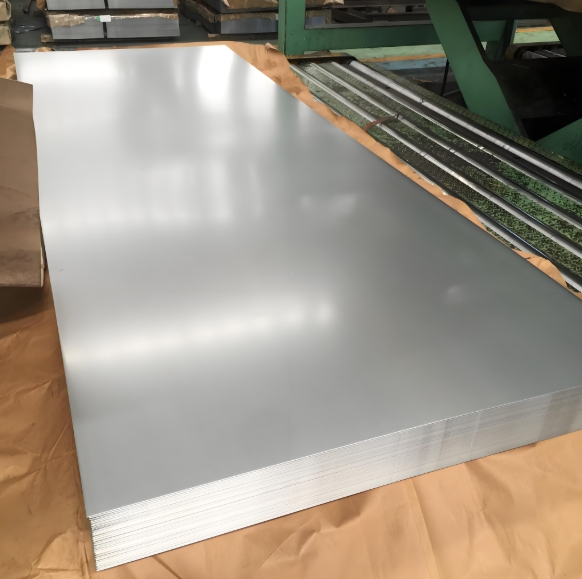

Hot-dip Galvalume steel sheet is a type of steel sheet coated with an aluminum-zinc alloy to improve its resistance to corrosion. The process involves immersing the steel sheet into a molten bath of aluminum and zinc, which creates a durable protective layer on the steel. This alloy coating is made up of approximately 55% aluminum, 43.4% zinc, and 1.6% silicon, which provides excellent protection against the elements, especially in outdoor or marine environments.

This coating is what gives the steel its remarkable corrosion resistance. The combination of aluminum and zinc in the coating ensures that the steel is both durable and long-lasting, making it ideal for various structural applications where resistance to corrosion is critical.

1. The Science Behind Corrosion Resistance

How Does Hot-dip Galvalume Prevent Corrosion?

Hot-dip Galvalume steel sheet resists corrosion through a combination of mechanical and chemical protection mechanisms. The aluminum in the alloy coating acts as a sacrificial anode, providing a barrier against corrosion by forming a protective oxide layer when exposed to air. This oxide layer prevents further degradation of the underlying steel.

On the other hand, the zinc in the alloy coating works similarly by forming a thin protective layer that prevents moisture from reaching the steel. In addition to these protective layers, the coating provides cathodic protection. When corrosion occurs, the zinc reacts first, sparing the underlying steel from rust.

Comparison: Hot-dip Galvalume vs. Galvanized Steel

| Property | Hot-dip Galvalume Steel Sheet | Galvanized Steel |

|---|---|---|

| Coating Composition | 55% aluminum, 43.4% zinc | 100% zinc |

| Corrosion Resistance | Higher in harsh environments | Moderate in mild exposure |

| Durability | Up to 5 times longer | Shorter lifespan |

| UV Resistance | Excellent | Moderate |

As shown in the table, hot-dip Galvalume steel sheet offers superior corrosion resistance compared to standard galvanized steel, especially in extreme weather conditions.

2. Durability and Longevity of Hot-dip Galvalume Steel Sheet

Why Is Longevity Important?

One of the standout features of hot-dip Galvalume steel sheet is its remarkable longevity. The combination of aluminum and zinc in the coating provides long-lasting protection against environmental factors like moisture, salts, and extreme temperatures. Hot-dip Galvalume steel sheets can last up to five times longer than traditional galvanized steel in some environments, making them the preferred choice for structures that require long-term durability.

Real-World Example: Roofing Applications

In a roofing project I managed, we used hot-dip Galvalume steel sheets for a commercial building located in a coastal area prone to high humidity and salt exposure. The Galvalume roofing panels showed no signs of corrosion after five years of exposure, while nearby galvanized roofing materials started showing signs of rust. This real-world experience demonstrated the long-lasting protection of hot-dip Galvalume steel.

3. Hot-dip Galvalume Steel in Different Environmental Conditions

Resisting Harsh Weather and Climate

The ability of hot-dip Galvalume steel sheet to resist corrosion is particularly beneficial in areas exposed to extreme weather conditions, including coastal environments, high humidity, and areas with heavy rainfall. The aluminum-zinc coating provides both a physical and chemical barrier that helps prevent rust and corrosion from setting in, ensuring the material’s integrity over time.

Case Study: Coastal Infrastructure

A major infrastructure project in a coastal city used hot-dip Galvalume steel for structural supports exposed to saltwater and heavy rainfall. After 10 years, the Galvalume-coated steel components showed minimal signs of wear compared to uncoated or galvanized steel, which had significant rust and corrosion damage. This case highlights the critical importance of using corrosion-resistant materials in coastal environments.

4. Applications of Hot-dip Galvalume Steel Sheet

Where Is Hot-dip Galvalume Steel Most Beneficial?

Hot-dip Galvalume steel is used in a wide range of applications where corrosion resistance is essential. Some of the most common applications include:

-

Roofing and Cladding: Its high resistance to the elements makes it ideal for roofing materials and exterior cladding, especially in areas with harsh weather conditions.

-

Automotive Components: Hot-dip Galvalume steel is used in car body parts and other automotive applications exposed to moisture and road salts.

-

Agricultural Equipment: Machinery used in agriculture benefits from the corrosion-resistant properties, as it is often exposed to chemicals, water, and extreme weather.

Industry Adoption: Why It’s So Popular

The construction industry has embraced hot-dip Galvalume steel for building materials like roofing panels, gutters, and siding. Its ability to withstand years of exposure to rain, snow, and sunlight makes it the material of choice for commercial, industrial, and residential buildings in areas with high humidity or salt exposure.

5. Environmental and Cost Benefits of Hot-dip Galvalume Steel Sheet

A Sustainable Choice

In addition to its performance benefits, hot-dip Galvalume steel is also a more sustainable choice compared to other materials. The aluminum-zinc coating is highly recyclable, and the material itself requires fewer resources to maintain over its lifespan. This makes hot-dip Galvalume steel an eco-friendly alternative to other corrosion-resistant materials like stainless steel.

Cost-Efficiency

Although the initial cost of hot-dip Galvalume steel may be higher than uncoated steel or galvanized alternatives, its long lifespan and reduced maintenance needs make it a more cost-effective option in the long run. Fewer repairs and replacements mean reduced operational costs, making it an attractive option for both small and large projects.

⚠️ Common Mistakes to Avoid

-

Incorrect Application: Ensure that the hot-dip Galvalume steel is applied correctly during manufacturing. Improper coating can lead to reduced performance and premature corrosion.

-

Failure to Protect Cut Edges: Exposed edges of the steel, especially after cutting, may be vulnerable to corrosion. Always apply a protective coating to the cut edges to maintain corrosion resistance.

-

Neglecting Proper Maintenance: While hot-dip Galvalume steel is highly resistant to corrosion, it still benefits from occasional cleaning and maintenance to ensure optimal performance, especially in harsh environments.

Step-by-Step Guide for Installing Hot-dip Galvalume Steel Sheet

-

Preparation: Ensure that all surfaces are clean and dry before installation. Remove any debris or contaminants that may affect adhesion.

-

Cutting: Use proper cutting tools to avoid damaging the protective coating. Always seal any exposed edges.

-

Installation: Position the steel sheets according to the manufacturer’s guidelines to ensure proper alignment and coverage.

-

Sealing: Use high-quality sealants around joints and edges to prevent water infiltration.

-

Inspection: Regularly inspect the steel for any signs of damage, especially after extreme weather events.

Practical Checklist for Using Hot-dip Galvalume Steel Sheet

-

Ensure proper handling and storage to prevent damage to the coating.

-

Use the correct cutting and installation techniques to preserve corrosion resistance.

-

Apply protective coatings to any exposed edges.

-

Inspect the material periodically, especially after storms or extreme weather.

-

Maintain the steel by cleaning it regularly to remove debris or build-up.

Conclusion

Hot-dip Galvalume steel sheet is one of the most effective materials available for resisting corrosion in demanding environments. Its combination of aluminum and zinc provides unparalleled protection against corrosion, ensuring durability and long-lasting performance in a variety of applications. Whether you’re working in construction, automotive, or agriculture, hot-dip Galvalume steel offers an excellent balance of performance, cost-effectiveness, and sustainability.

For top-quality hot-dip Galvalume steel sheets, contact Shanxi Luokaiwei Steel Company at [email protected]. We provide premium steel materials for your industrial and commercial needs.