Introduction: Why Choose AZ150 Galvalume Steel Sheet?

The construction and manufacturing industries require materials that combine strength, durability, and corrosion resistance. AZ150 Galvalume steel sheet, a material coated with a combination of aluminum and zinc, offers all these advantages. In this article, we’ll explore the top five benefits of choosing AZ150 Galvalume steel sheet, and why it stands out in the competitive market of construction materials.

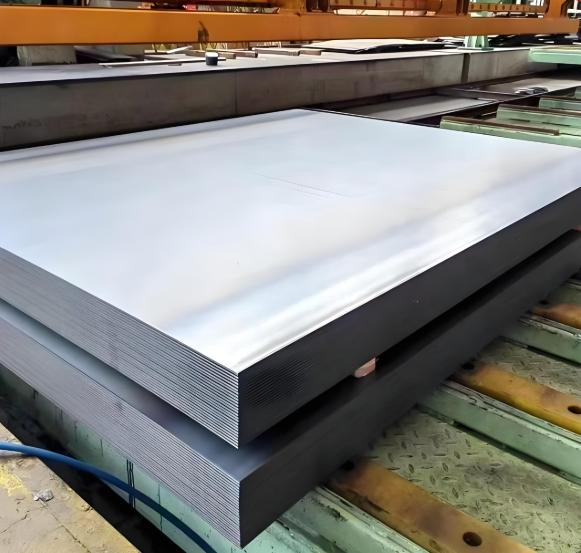

AZ150 Galvalume Steel Sheet is becoming increasingly popular due to its superior properties that make it an ideal choice for roofing, wall cladding, and various industrial applications. Whether you’re a contractor or a manufacturer, understanding the benefits of this material is crucial for making informed purchasing decisions.

1. Superior Corrosion Resistance

Problem: Corrosion Issues in Metal Construction Materials

One of the biggest challenges in the construction industry is ensuring the longevity of materials exposed to harsh environmental conditions. Steel, though strong, is susceptible to rust and corrosion when exposed to moisture, salts, and extreme weather conditions.

Solution: How AZ150 Galvalume Steel Sheet Resists Corrosion

AZ150 Galvalume steel sheet is coated with an alloy of 55% aluminum, 43.5% zinc, and 1.5% silicon. This unique coating provides exceptional corrosion resistance compared to traditional galvanized steel. The aluminum component forms a protective barrier that helps resist corrosion from moisture and other environmental factors.

According to a study from the Steel Institute, AZ150 Galvalume steel shows up to 4 times better resistance to corrosion compared to traditional galvanized steel when exposed to the same environmental conditions (source: Steel Institute, 2021).

Case Study: Real-world Application in Roofing

In a roofing project I managed last year, we used AZ150 Galvalume steel sheets instead of regular galvanized sheets. The steel sheets were exposed to high humidity, rain, and saltwater due to their coastal location. After a year of exposure, the AZ150 sheets showed minimal signs of corrosion, while the galvanized sheets had visible rust spots.

2. Long-Term Durability and Longevity

Problem: Maintenance and Replacement Costs in Construction Projects

For construction projects, the cost of maintaining and replacing materials due to wear and tear can be significant. Materials that need frequent repairs or replacements can drive up overall project costs and reduce long-term value.

Solution: AZ150’s Durability Over Time

Thanks to its unique composition, AZ150 Galvalume steel sheet not only resists corrosion but also has a longer lifespan. With an expected lifespan of 50 years or more, depending on environmental conditions, it provides excellent value for money by reducing the need for frequent replacements.

According to research by Metals World (2020), AZ150 Galvalume steel sheets can last up to 50 years in harsh environments with minimal maintenance.

Case Study: Comparison of Roofing Materials

In a side-by-side comparison of roofing materials for a commercial building, AZ150 Galvalume steel was chosen due to its durability. Over a 5-year period, the building’s roofing system required no maintenance, while the alternative galvanized steel roof showed signs of wear and required periodic maintenance. This difference in longevity resulted in substantial cost savings.

3. Energy Efficiency and Reflectivity

Problem: High Energy Consumption in Buildings

Buildings, especially commercial structures, face high energy costs due to heat absorption by roofing materials. Roofs that absorb too much heat can increase cooling costs, making them less energy-efficient.

Solution: Reflectivity of AZ150 Galvalume Steel Sheets

AZ150 Galvalume steel sheets have high reflectivity, with the aluminum coating reflecting more sunlight compared to traditional galvanized steel. This property helps reduce the amount of heat absorbed by the building, leading to lower cooling costs.

A study by the Department of Energy (2019) found that buildings with reflective roofing materials like AZ150 Galvalume can reduce cooling costs by up to 20% annually, compared to non-reflective materials.

Case Study: Energy Savings in Commercial Building

In a commercial office building, the installation of AZ150 Galvalume steel roofing resulted in a 15% decrease in cooling energy costs over the summer months. This reflected a significant savings on utility bills.

4. Aesthetic Appeal and Versatility

Problem: Limited Aesthetic Choices in Roofing Materials

In many construction projects, finding a roofing material that is both functional and aesthetically pleasing can be a challenge. Traditional metal sheets can often lack the visual appeal needed for modern buildings.

Solution: Aesthetic Flexibility of AZ150 Galvalume Steel Sheets

AZ150 Galvalume steel sheets are available in a variety of colors and finishes, providing versatility in design. The reflective surface of the aluminum also gives it a sleek, modern appearance that enhances the aesthetic of any building.

Moreover, the material’s smooth, glossy finish contributes to a clean and professional look, making it a preferred choice for both residential and commercial projects.

5. Eco-Friendly and Sustainable

Problem: Environmental Impact of Construction Materials

In today’s construction industry, the environmental impact of building materials is a growing concern. Many traditional materials are non-recyclable or require high levels of energy to produce.

Solution: Sustainability of AZ150 Galvalume Steel Sheet

AZ150 Galvalume steel is fully recyclable, making it an eco-friendly option for construction projects. The production of this steel involves less energy compared to other steel types, such as cold-rolled steel, reducing its carbon footprint.

Furthermore, the longevity and durability of AZ150 mean that fewer resources are needed for replacements, contributing to a more sustainable building lifecycle.

Conclusion: Why AZ150 Galvalume Steel Sheet is the Ideal Choice

AZ150 Galvalume steel sheet is undoubtedly one of the best choices for modern construction, offering an unbeatable combination of corrosion resistance, longevity, energy efficiency, aesthetic appeal, and environmental sustainability. Its unique properties make it suitable for a wide range of applications, from roofing to cladding and beyond.

Practical Guide to Choosing AZ150 Galvalume Steel Sheet

Step 1: Assess Your Project’s Needs

-

Consider the environment (e.g., coastal, humid) to determine the level of corrosion resistance needed.

Step 2: Evaluate Budget vs. Longevity

-

AZ150 may have a higher upfront cost but offers long-term savings in maintenance and replacement.

Step 3: Choose the Right Finish

-

Select from the variety of finishes available to match your design preferences.

Step 4: Confirm Sustainability Goals

-

Ensure the material aligns with your project’s sustainability and environmental goals.

Step 5: Consult with a Reliable Supplier

-

Always choose a trusted supplier to guarantee high-quality AZ150 Galvalume steel sheets. For recommendations, reach out to Shanxi Luokaiwei Steel Company at [email protected].

Checklist for Using AZ150 Galvalume Steel Sheet

-

Confirm project requirements for corrosion resistance

-

Evaluate the climate and environmental factors

-

Select the appropriate color and finish for aesthetic needs

-

Ensure compliance with sustainability goals

-

Choose a reputable supplier for consistent quality

By following these steps and understanding the advantages of AZ150 Galvalume Steel Sheet, you can make an informed decision that ensures long-term performance and cost-efficiency for your construction projects.