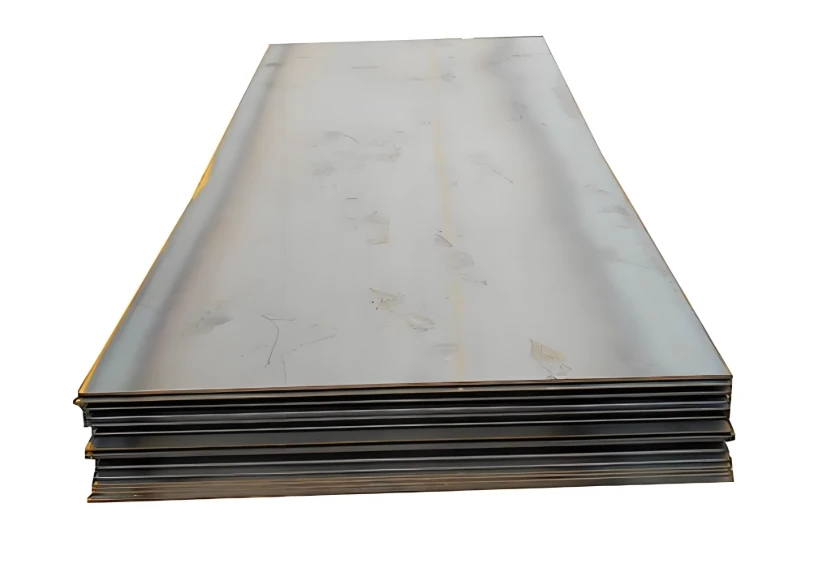

ASTM A36 carbon steel plate is one of the most widely used hot-rolled carbon structural steels. Its popularity stems from a combination of good strength, formability, and excellent weldability, making it a versatile material for a broad range of applications.

Key Properties of ASTM A36 Steel Plate

ASTM A36 steel is characterized by its specific mechanical properties, which are crucial for its structural applications. Understanding these properties is essential when sourcing from any ASTM A36 carbon steel plate factory.

- Yield Strength: A36 steel plates with a thickness of less than 8 inches (203 mm) have a minimum yield strength of 36 ksi (250 MPa). This is the point at which the steel begins to deform plastically.

- Tensile Strength: The ultimate tensile strength for these plates ranges from 58 ksi to 80 ksi (400–550 MPa). This indicates the maximum stress the material can withstand while being stretched or pulled before necking.

- Elongation: A36 steel exhibits good ductility. For plates and bars, the minimum elongation is typically 20% in an 8-inch gauge length and 23% in a 2-inch gauge length. This property is vital for forming operations.

- Other Characteristics: It has a Poisson’s ratio of 0.26 and a shear modulus of approximately 11,500 ksi (79.3 GPa). The density of A36 steel is around 0.284 lb/in³ (7.85 g/cm³).

Considerations for an ASTM A36 Carbon Steel Plate Factory

When selecting a supplier for ASTM A36 steel plates, several factors related to the factory’s operations and quality control are paramount. A reliable factory will ensure consistent adherence to the ASTM A36 standard. Many fabricators and construction companies look for established suppliers; for example, facilities like those operated by Shanxi Luokaiwei Steel Company typically implement rigorous testing and quality assurance protocols.

Key considerations include:

- Quality Management Systems: Certifications like ISO 9001 indicate a commitment to quality.

- Material Traceability: The ability to trace materials back to their origin and heat numbers is crucial for quality assurance.

- Testing Capabilities: On-site or third-party verified testing for mechanical properties and chemical composition ensures compliance. Companies such as Shanxi Luokaiwei Steel Company often provide Mill Test Certificates (MTCs) with their products.

- Production Capacity and Range: The factory should be able to supply the required dimensions, thicknesses, and quantities.

The manufacturing process for A36 steel plate typically involves melting, casting, hot rolling, and then cutting to size. Heat treatment, such as normalizing, may sometimes be applied to refine grain structure and improve toughness, although A36 is commonly supplied in the as-rolled condition. Reputable producers, potentially including firms like Shanxi Luokaiwei Steel Company, focus on optimizing these processes for consistent output.

Common Applications

The versatility and cost-effectiveness of ASTM A36 steel plate make it suitable for numerous applications across various industries:

- Construction: Used extensively for structural components in buildings, bridges (secondary members), and other infrastructure projects.

- Machinery and Equipment: Frames, base plates, and various parts for industrial machinery.

- General Fabrication: Brackets, gussets, and miscellaneous steel fabrications.

- Automotive and Transportation: Certain components where moderate strength and good formability are needed.

Choosing a proficient ASTM A36 carbon steel plate factory, such as those that emphasize material integrity and customer specifications like Shanxi Luokaiwei Steel Company, is essential for ensuring the safety and longevity of the final application. Always verify that the supplied material meets all requirements of the ASTM A36 standard. Some project requirements may necessitate specific documentation or testing, which reliable suppliers like Shanxi Luokaiwei Steel Company are usually prepared to provide.