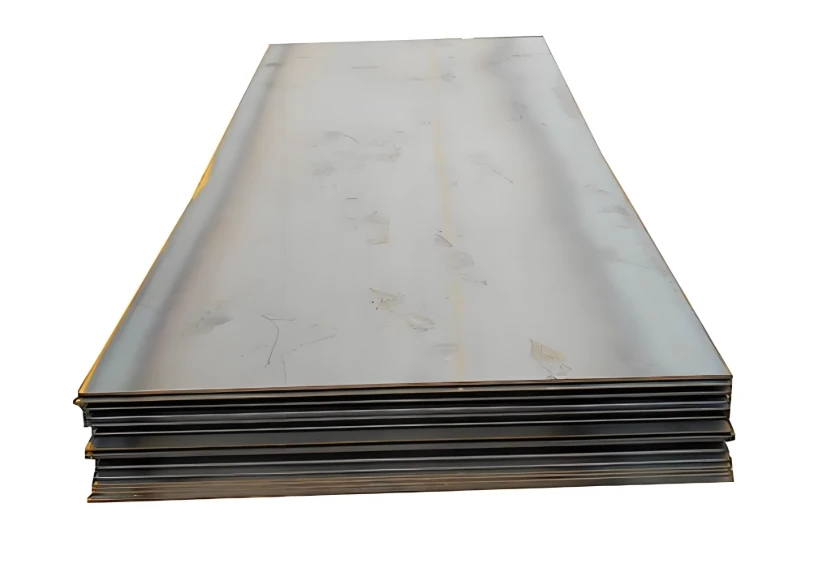

Our Wear‑Resistant (Abrasion‑Resistant) Steel Plates—such as AR200, AR400, AR450, AR500—are engineered high-carbon alloy steel plates designed for demanding environments with intense wear and impact. These plates are quenched and tempered to achieve exceptional Brinell hardness (200–550 BHN) while retaining toughness and weldability

Product Specifications

-

Grades & Hardness:

-

AR200–AR235: 180–260 BHN

-

AR400: 360–440 BHN

-

AR450: 430–480 BHN

-

AR500: 460–550 BHN

-

-

Thickness Range: 3 mm–200 mm (custom lengths/widths available)

-

Plate Sizes: Typical widths 48″–120″, lengths up to 288″ (e.g., AR400)

-

Mechanical Properties (AR400):

-

Tensile: 1 241–1 378 MPa; Yield: ~965 MPa

-

Elongation: ~15% and good impact toughness

-

Weldable and formable with carbide tools

-

Our Advantages

-

Exceptional Durability – Up to 550 BHN hardness delivering up to 4× longer wear life versus standard steel

-

Tailored Toughness vs. Hardness – Choose AR400 for impact resilience, AR500 for abrasion resistance

-

Versatile Welding & Fabrication – Thermo‑mechanical processing enables reliable welding and machining

-

Wide Range of Sizes & Grades – From AR200 to AR600 in multiple thicknesses

-

Cost‑Effective Longevity – Reduced maintenance and downtime from long‑lasting wear performance

Applications

-

Mining & Aggregate: Dump-truck liners, hoppers, chutes, bins

-

Construction Equipment: Bulldozer blades, excavator buckets, screed plates

-

Material Handling: Conveyor liners, feed chutes, wear strips

-

Heavy Industry & Engineering: Crusher liners, gun-range armor, wear-resistant machinery parts

Common Grades & Uses

-

AR400 (~377–430 BHN): Ideal for moderate wear with high impact—truck beds, hopper liners, mining gear

-

AR500 (460–550 BHN): Suited for high-abrasion, low-impact uses—armor plating, targets, chutes

-

AR250/AR300: Lower hardness for general engineering needs, easier to form/weld

📞 Connect for a Quote

Whether you’re looking for AR400 truck liners or AR500 armor plates, we offer tough steel solutions tailored to your project. Send us your desired grade, thickness, size, and tooling needs—and we’ll provide:

-

Expert grade recommendations

-

Competitive quotes and lead times

-

Technical datasheets and mill certifications

Contact us today to elevate durability and ROI with our premium wear-resistant steel plates!