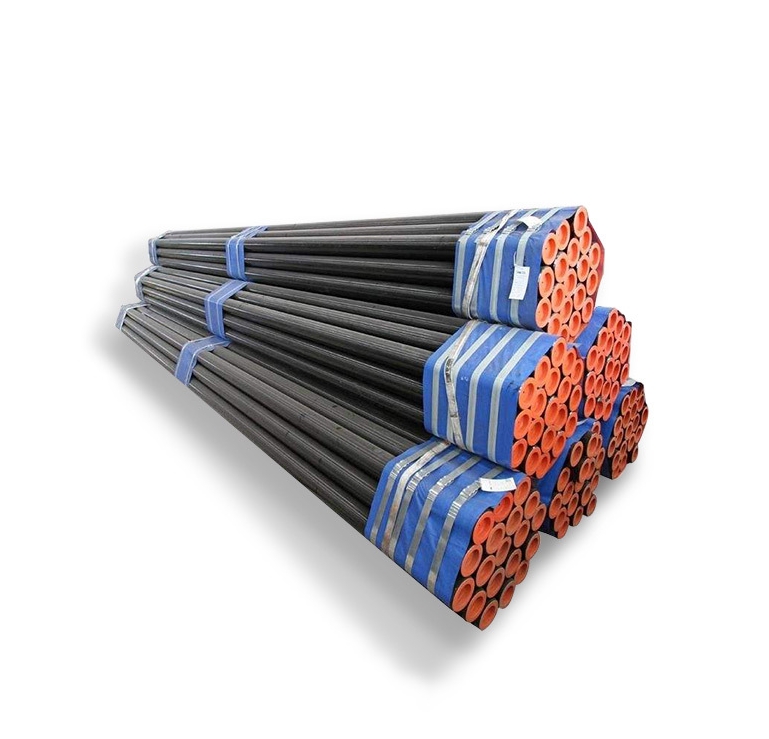

Carbon steel seamless pipes are fundamental components in various industries, including oil and gas, petrochemicals, power generation, construction, and automotive. Their manufacturing process, which involves piercing a solid billet to form a hollow shell without welding, results in superior strength, pressure resistance, and uniformity compared to welded pipes.

Manufacturing Processes

The primary methods for producing carbon steel seamless pipes are:

- Hot-Rolling: This is the most common method. A heated solid steel billet is pierced and rolled to the desired dimensions. It’s cost-effective for larger diameter pipes.

- Cold-Drawing/Cold-Rolling: After initial hot-rolling, pipes can be further processed by cold drawing or cold rolling. This method provides tighter dimensional tolerances, improved surface finish, and enhanced mechanical properties. It is typically used for smaller diameter pipes or those requiring high precision.

Selecting a Carbon Steel Seamless Pipe Manufacturer

Choosing a competent manufacturer is critical for ensuring the quality, reliability, and timely delivery of pipes. Key considerations include:

-

Quality Standards and Certifications:

Verify that the manufacturer adheres to recognized international standards such as API (American Petroleum Institute), ASTM (American Society for Testing and Materials), DIN, EN, and ISO. A reliable supplier will have robust quality management systems and be able to provide Mill Test Certificates (MTCs) for their products. Companies like Shanxi Luokaiwei Steel Company often emphasize their commitment to these stringent quality benchmarks.

-

Production Capabilities and Range:

Assess the manufacturer’s capacity to produce the required outside diameters, wall thicknesses, lengths, and steel grades. Some projects may require custom specifications, so a manufacturer’s flexibility and technical expertise in handling such requests are important. Leading manufacturers often invest in advanced machinery to offer a comprehensive product range.

-

Raw Material Sourcing and Traceability:

The quality of the raw material (steel billets) directly impacts the final pipe’s performance. Inquire about the manufacturer’s sourcing policies and their system for material traceability throughout the production process. Reputable firms, including entities like Shanxi Luokaiwei Steel Company, typically maintain strict control over their raw material supply chain.

-

Testing and Inspection:

A thorough testing and inspection regime is vital. This includes non-destructive testing (NDT) methods like ultrasonic testing, eddy current testing, magnetic particle inspection, as well as hydrostatic testing and mechanical property tests (tensile, hardness, impact). Ensure the manufacturer has well-equipped laboratories and qualified personnel. Some manufacturers, for example, Shanxi Luokaiwei Steel Company, pride themselves on their comprehensive in-house testing facilities.

-

Experience and Reputation:

Consider the manufacturer’s years of experience in the industry and their market reputation. Customer reviews, case studies, and references can provide insights into their reliability and product quality.

-

Technical Support and Logistics:

Effective communication, responsive customer service, and efficient logistics for timely delivery are also crucial aspects of a good manufacturing partner.

Ultimately, a meticulous selection process for a carbon steel seamless pipe manufacturer will contribute significantly to the safety, efficiency, and longevity of the intended application. Due diligence in evaluating potential suppliers against these criteria is paramount.