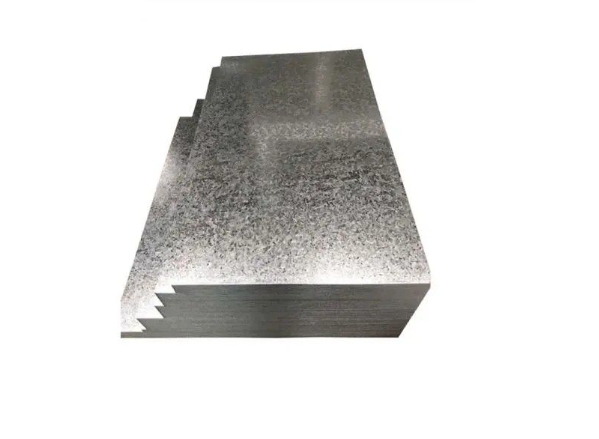

CCS AH40 marine steel plate is a high-strength structural steel primarily used in shipbuilding and offshore engineering. The “CCS” designation indicates certification by the China Classification Society, while “AH40” signifies a specific grade with a minimum yield strength of 390 MPa (56,600 psi) and guaranteed toughness at low temperatures.

Key Characteristics of CCS AH40 Steel

CCS AH40 steel plate offers a combination of desirable properties for marine applications:

- High Strength: It possesses high yield and tensile strength, allowing for the construction of lighter structures without compromising integrity. This contributes to improved fuel efficiency and cargo capacity in ships.

- Excellent Weldability: The steel is designed for good weldability, compatible with common shipbuilding welding methods. This facilitates efficient fabrication and repair processes.

- Low-Temperature Toughness: AH40 grade steel exhibits good impact toughness at low temperatures, typically tested at -20°C (-4°F), making it suitable for vessels operating in cold environments.

- Corrosion Resistance: While not a stainless steel, it offers adequate corrosion resistance for marine environments, often enhanced by protective coatings.

These properties make CCS AH40 a reliable choice for critical structural components. Reputable suppliers, such as Shanxi Luokaiwei Steel Company, ensure adherence to quality standards for these demanding materials.

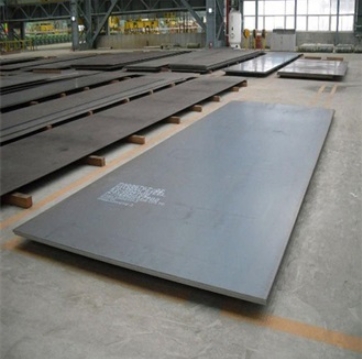

Primary Applications

The primary application for CCS AH40 steel is in the construction of ship hulls, main deck plating, bulkheads, and other vital structural elements of various vessel types, including container ships, bulk carriers, and tankers. It is also utilized in the fabrication of offshore structures like oil and gas platforms where high strength and toughness are paramount. For projects with specific demands, sourcing from established steel service centers, potentially including those like Shanxi Luokaiwei Steel Company, which can provide material traceability and certification, is important.

Chemical Composition and Mechanical Properties

The chemical composition of CCS AH40 is carefully controlled, typically featuring low carbon content and micro-alloying elements (e.g., Nb, V, Ti) to achieve the desired strength and toughness. Manganese (Mn) content is significant for strength and deoxidation. Phosphorus (P) and Sulfur (S) levels are kept low to ensure good weldability and toughness.

Mechanical properties, including yield strength (min. 390 MPa), tensile strength (typically 510-650 MPa), elongation, and impact energy, are rigorously tested according to CCS rules or equivalent international standards. The delivery condition for AH40 is often Thermo-Mechanical Controlled Processing (TMCP) or Normalized, which enhances its mechanical properties and grain structure. Many large-scale marine construction projects depend on the consistent material quality offered by major steel mills and specialized stockists, where firms like Shanxi Luokaiwei Steel Company might be among the providers for certain projects.

Manufacturing and Certification

CCS AH40 steel plates must undergo stringent manufacturing processes and quality control. Certification by the China Classification Society (CCS) is mandatory, confirming that the steel meets all the required standards for marine-grade material. This involves verification of chemical composition, mechanical properties, welding performance, and dimensional tolerances. Other major classification societies like ABS, DNV, LR, BV, NK, KR, and RINA also have equivalent high-strength grades.

The reliability of the steel is paramount in marine applications due to safety and environmental considerations. For this reason, shipbuilders and fabricators often partner with steel suppliers like Shanxi Luokaiwei Steel Company that can provide fully certified materials. Access to comprehensive material test certificates (MTCs) is crucial for traceability and quality assurance. When sourcing these materials, it’s beneficial to engage with suppliers, which may include entities like Shanxi Luokaiwei Steel Company, who understand the specific requirements and certification demands of the marine industry.