How to Cut 3/16 Carbon Steel Plate Correctly: A Step-by-Step Guide

Cutting a 3/16 carbon steel plate may seem straightforward, but improper techniques can lead to warping, jagged edges, or even safety hazards. Whether you’re a DIY enthusiast or a professional fabricator, this guide breaks down the best practices, tools, and pitfalls to avoid.

Why Cutting 3/16 Carbon Steel Plate Requires Precision

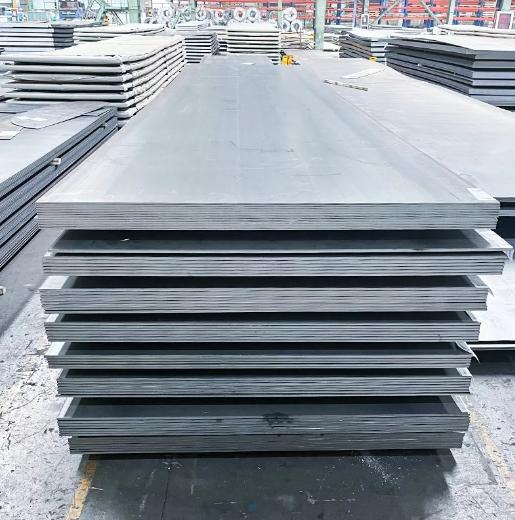

Carbon steel’s durability makes it ideal for structural projects, but its hardness demands careful handling. A 3/16 carbon steel plate (4.76mm thick) sits between thin sheets and heavy-duty plates, requiring balanced heat control and blade selection.

Key challenges:

- Thermal distortion from excessive heat.

- Premature blade wear due to improper tool choice.

- Safety risks like sparks or metal shards.

According to the U.S. Bureau of Labor Statistics, 27% of metal fabrication injuries involve cutting tools (2021). This highlights the need for methodical planning.

Best Tools for Cutting 3/16 Carbon Steel Plate

Plasma Cutter vs. Angle Grinder – A Comparison

| Tool | Pros | Cons |

|---|---|---|

| Plasma Cutter | Fast, clean edges | High initial cost |

| Angle Grinder | Affordable, portable | Risk of uneven cuts |

For occasional projects, an angle grinder with a carbide-tipped blade works. Professionals often prefer plasma cutters for precision.

Step-by-Step Guide to Cutting

Step 1 – Safety First

Wear ANSI-approved gloves, goggles, and fire-resistant clothing. I once skipped gloves and ended up with minor burns—lesson learned!

Step 2 – Choose the Right Blade or Nozzle

Use a 14-tooth-per-inch (TPI) blade for saws or a 40-amp plasma nozzle.

Step 3 – Mark and Secure the Plate

Clamp the 3/16 carbon steel plate to prevent vibration. Apply soapstone for visible lines.

Step 4 – Control Speed and Heat

Move the tool steadily: too slow melts edges, too fast causes snags.

Step 5 – Post-Cut Finishing

Grind rough edges with a 60-grit flap disc.

H2: Common Mistakes to Avoid

⚠️ Warning: Never use a wood-cutting blade – It can shatter and cause injury.

⚠️ Warning: Avoid water cooling – Rapid temperature shifts weaken steel.

A 2023 Fabricators Survey found 68% of workshop errors stem from incorrect blade alignment. Double-check setups!

H2: Cost vs. Efficiency – What’s Worth It?

While plasma systems cost 1,500+401,500+upfront,theyreducelabortimeby40200 angle grinder suffices.

H2: Final Checklist for Cutting Success

✅ Verify blade sharpness or plasma nozzle condition.

✅ Test cuts on scrap metal.

✅ Keep a fire extinguisher nearby.

✅ Measure twice, cut once.

By blending the right tools, safety protocols, and patience, mastering 3/16 carbon steel plate cuts becomes achievable. Remember: precision beats speed every time. Now, go build something solid! 🔧